Operation of the car on poor-quality roads leads to rapid wear of the suspension. A complete repair of all components will be quite expensive on any machine, but some operations can be performed independently by the driver without the help of the maintenance station, such as replacing the tie rod or tips.

In any wheeled car there is a steering wheel which, through a worm or rack gear, transmits the force for the simultaneous rotation of the driving wheels. Repair kits of popular car brands for this operation are sold in almost every specialty store. It remains only to prepare the necessary tool, and you can proceed.

Content

- 1 Malfunction steering steering

- 2 Symptoms

- 3 How to change the steering tips

Malfunction steering steering

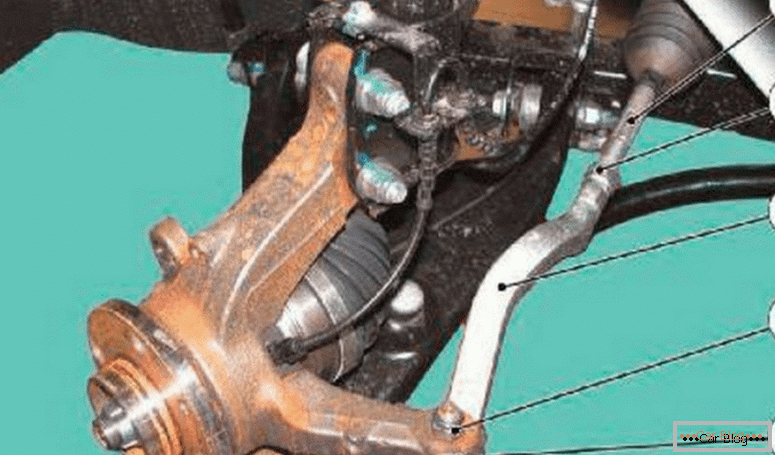

Before replacing the tie rod, you need to know that the most frequently failing suspension elements are ball joints of the steering rod tips. Production can be seen after removal. Noticeable backlash is formed after partial erasure of the spherical structural element.

When there was a shortage of spare parts, then in the old “classic” VAZs, car owners tried to restore these elements on their own. However, this was not for long. Now the replacement of the tips of the steering gear passes without such torment.

About the problem with this part of the suspension driver will tell a clear knock in the front. Tightening up with repairs in such a situation is not worth it, since if a breakdown happens on the run of a car, it will be difficult to avoid an accident.

Symptoms

Replacing the steering tips usually begins with a diagnosis. The problem can be identified by the following features:

- there is an increase in the backlash of the steering wheel;

- there was a tight rotation of the steering wheel;

- knocks are heard in the engine compartment and steering;

- there is a steering beating;

- if the car moves straight without turning the steering wheel, then spontaneous “wagging” of the car can occur in different directions.

One of these symptoms is enough to begin diagnosing the suspension for the performance of the steering tips.

You can make an independent check of this node:

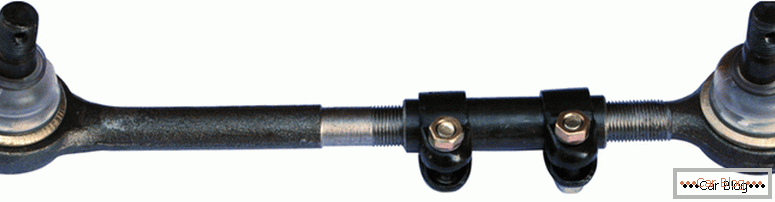

- on the side of the adjusting the clamp should be tightly tightened clamp;

- rubber anthers must be without damage, so that dirt or dust does not penetrate into the working joint, even small punctures or cracks are not allowed;

- The working offset along the axis of the finger by 1-1.5 mm is considered permissible; you can check it yourself when the partner rotates the steering wheel and the driver holds the controlled node under the car.

Identified deficiencies need to be addressed by replacing the spent parts.

How to change the steering tips

The job of replacing tips fits into a simple algorithm:

- Raise one side of the car with a jack and remove the wheel for further work;

- Remove the castellated locknut from the pin;

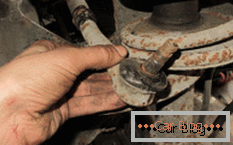

- Knock a finger out of its position with the help of a puller and a hammer, but do not damage the bipod with a blow;

- Remove the tip from the coupling;

- Remove the rubber boot and disconnect the rail;

- Install new traction.

-

- Step 1. Turn off the nut

-

- Step 2. Spin the finger

-

- Step 3. Disconnect the traction.

-

- Step 4. Apply the puller

-

- Step 5. Disassemble the ball joint

-

- Step 6. Change the hinge and assemble the structure

Before removing the old thrust, it is advisable to measure the distance from the coupling to the conventional axis of the tip. New traction must be set in measured dimensions. Next, conducts the entire assembly in the reverse order of disassembly. When tightening the clamp must be careful not to drag it.

It is desirable to change both tips, it will save time and prevent potential problems with the suspension.

After self-replacement of the tips, it is necessary to adjust the camber / toe in the car. This procedure should be done at a special professional stand. Without it, tires can quickly “eat”, which will lead to additional unnecessary costs.