Those who love speed and real drive, often prefer cars with turbo engines. The turbine in the car is needed for forcing more air into the engine, which just contributes to the increase in power. But turbo engines have one significant disadvantage - the supercharger is fragile and often fails. Therefore, each owner of such a car can come in handy with the ability to repair the turbine with their own hands.

Content

- 1 Design features

- 2 Symptoms and Troubleshooting

- 3 We understand turbine

- 4 repair process

- 5 Posleslovie

Design features

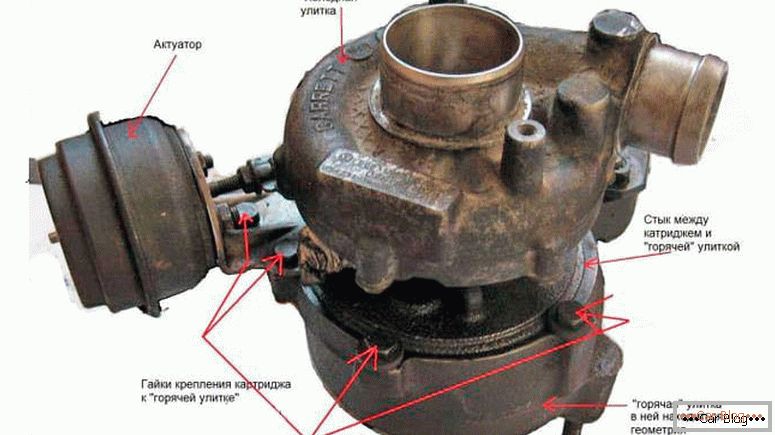

Device turbocharger

In general, the design of the turbine is nothing complicated. It consists of only several key elements:

- enclosures;

- pair of snails connected by the shaft;

- pairs of bearings;

- several sleeves.

The shaft is made of steel, and the body is usually aluminum (today there are ceramic turbines, but in this article we will consider the repair of classical type turbines). If damage has appeared on these parts, there is only one way out - replacement. However, most other problems with the turbocharging system can be diagnosed and fixed without the help of experts. It is about how to check the turbine and fix it, and we will tell further.

Symptoms and Troubleshooting

Often the main cause of a turbine breakdown is the negligence of its owner - the late service carried out was killed by more than one blower. If THAT is carried out on time, you can save both the turbine and your wallet from shocks. So, consider a few signs that indicate the breakdown of the turbocharger of your car:

White smoke may indicate that the turbocharger drain oil pipe is clogged.

- Exhaust blue during an increase in engine speed and lack of it when the revolutions become normal. Often this symptom occurs when the oil supplied to the slide bearings falls into the combustion chamber of the motor.

- Black smoke comes out of the car’s chimney. It is possible that there is an air leak in the injection line, therefore a mixture overpriced with gasoline is fed into the combustion chamber, during the combustion of which black smoke appears.

- Dense white smoke may indicate that the turbocharger drain oil pipe is clogged. The problem is solved by cleaning the highways.

- Oil consumption too high (up to a liter per 1000 km of run). It is also possible to flow turbines. You should also carefully inspect the nozzles for cracks, and check their joints for tightness.

- Sluggish overclocking dynamics. This happens if the motor does not have enough air. The reason may also be covered in the turbocharger control unit.

- When the engine is started whistling is heard. Perhaps a gap has appeared in the air supply system through which air is drawn in.

- During operation of the turbine, a rattle is heard. This may indicate a crack or other damage to the turbine housing itself. Most likely, such a supercharger will have to be replaced.

- The turbine makes too much noise. There may be two reasons: due to the change in the rotor gaps, it can touch the case during rotation, and the second reason is that the turbocharger oil pipe is clogged.

- A sharp increase in fuel consumption or an increase in the amount of harmful substances in the exhaust can often be the result of problems with the supply of air to the supercharger.

The crack on the turbine housing

We understand turbine

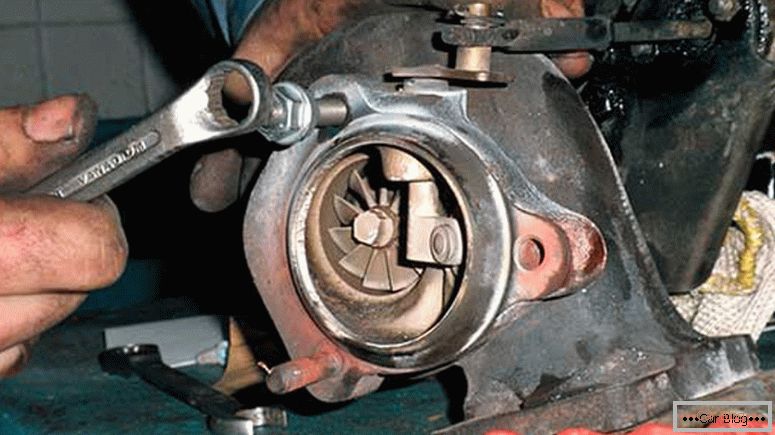

Before you start repairing the turbocharger, you must remove the turbine from the car and disassemble it. We do this in the following order:

- We disconnect the pipelines that lead to the turbine. The process must be approached with accuracy - at this stage you can damage the device.

- Dismantle both snails. Removing the turbine snail, will have to make some effort, with the same compression problems should not arise. At this stage it is important not to break the turbine wheel.

- When the snails are removed, you need to check the turbine shaft. If you do not find a backlash, then the problem is not in the shaft. One should not forget, however, that longitudinal play in the range of 1 mm is a permissible phenomenon.

- Now, using the pliers, remove the wheels of the turbine. Performing this operation, do not forget - the shaft often has a left-hand thread.

- After that, remove the thrust bearing.

- From the end of the turbine we dismantle the liners. Most often they, like sliding bearings, are fixed by means of retaining rings, so this part of the process can take a long time.

If the turbine has already been disassembled, be sure to wash and clean all its elements (regardless of whether they require repair or not).

Repair process

Before you start repairing, you need to disassemble the turbine.

When the process of removing the supercharger is completed, you can begin to repair. To do this, you need to purchase a special repair kit for turbocharging. There must be all the necessary stuff - rings, hardware, bearings and seals. So, let's begin:

- To begin, check the reliability of fixing nominal liners. If there is a strong backlash, they should be machined, it will be useful to also balance the shaft. After grooving the liners clean and lubricate with oil.

- The internal retaining rings are placed in the cartridge so that they are in special grooves.

- Now install the liner turbine. It is also lubricated with engine oil and fix the retaining ring.

- Next, install the compressor liner and bushings (it should be well lubricated).

- Put the plate on the sleeve and tighten it with the existing bolts.

- At the final stage, we install the oil scraper ring and put in place the anti-wear plate. After this, we put in place two snails.

We considered the general principle of disassembling a turbocharger. In your car, the design of the turbine may differ slightly from the example given by us. However, the algorithm will still be similar to the above.

Posleslovie

If the turbine does not require serious repair, then the process of its disassembly and preventive replacement of some elements will not require any special skills or time-consuming. In this process, the main thing is to be extremely attentive and careful.