After the car has been painted, it is necessary to coat it with varnish, which will further protect the car from rust, and also give shine to the car and improve its appearance. In the production of varnishes for cars used synthetic resin. In order not to lose money with a varnish and the car looked like new, it is necessary to choose the right one. car paint.

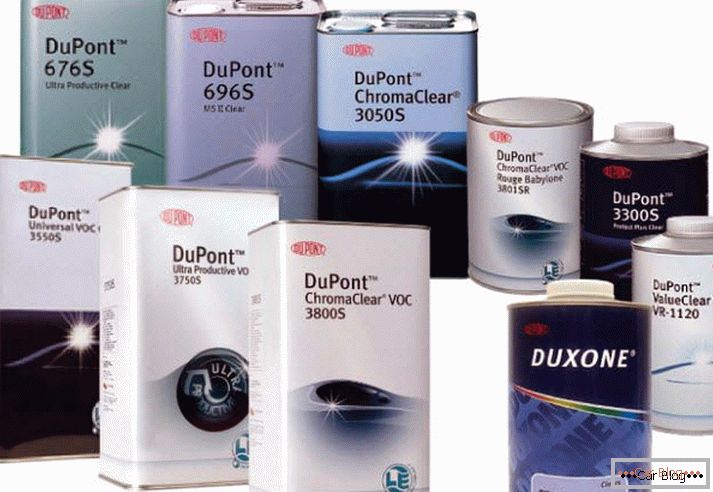

A wide range of varnishes for cars

The history of the appearance of car paints began in the 19th century, then there was a need for high-quality and fast-drying materials.

In our time, automotive lacquer, which is designed to paint the car in most cases - 2-component. The two-part varnish is very resistant to environmental influences, has an excellent gloss.

Before painting the car, you can see that the varnish is packaged with a certain color. Also, there are options when the car painter chooses a certain varnish for a certain paint in order to finally get the desired color of the car.

To date, there are varnishes for cars:

- acrylic;

- metallized;

- cellulose;

- glyphthalic;

- acrylpolyurethane;

- polyurethane.

Cellulose varnish

The very first varnish, which appeared on the market. Nitrocellulose is used for the production of this varnish. What is good for this varnish is that it has a short drying time. There are also disadvantages:

- flammable;

- evaporates quickly;

- over time, it burns out and turns yellow, but if you apply varnish in several layers, you get a good result;

- requires careful polishing.

Today, cellulose lacquer is almost not for sale, it is not even in the catalogs of serious paint and varnish manufacturers.

Glyphthalic varnish

The basis of the glyptal varnish includes synthetic resins. Glyphthalic lacquer replaced the pulp since 1930. This varnish has excellent properties that facilitate the process of painting a car:

- excellent covering ability;

- Shine appears immediately after painting;

- durable and elastic film is formed after drying.

Disadvantages also have this varnish:

- the glyptal varnish dries slowly enough;

- the film hardens only in a day;

- dust protection is required.

To speed up the drying process, today glyptal varnishes are mixed with a hardener. But if the glyptal lacquer is compared with acrylic or polyurethane, then the former is clearly lagging behind in its characteristics and the durability of the coating is clearly weaker.

Recommended article: Repair of the Solex carburetor 21083 (video instruction)Lacquer features:

- It is necessary to observe the temperature regime for the environment to be at a certain temperature. The lower limit of the ambient temperature: + 20C.

- To speed up the drying, it is better to use a drying chamber.

- The higher the temperature, the more solvent is required.

- It is necessary to observe a certain viscosity, to prevent too thick composition, in order to avoid a viscous film, due to which surface swelling and other irregularities may appear.

- Thermoplastic base is not suitable.

- During application, there should be a distance of 20 to 25 cm between the surface of the car and the nozzle.

To make the varnish lay beautifully, you need to go through the following steps:

- apply a very thin first layer, this will be a clutch film;

- after 5 minutes, apply the second layer in a different direction;

- if necessary, apply a third layer;

- after 2-3 days have passed, the car should be coated with a single-component paint, and then, after 12 hours, apply the composition of the glyptal varnish with a hardener;

- dry for the first 10 minutes at a temperature of + 20 ° C;

- then dry for 30-40 minutes at a temperature of + 60-80C.

There is also a hot method of applying glyptal lacquer, which is suitable only for single-component paints, therefore it is used very rarely, because it requires an increase in temperature and the mixture, and the surface for painting.

Metallic lacquer

It appeared around 1960, it contains a metallic dye and tinsel of aluminum or bronze, the size of which is approximately 1 micron. Today, many colorful compositions are made on the basis of acrylic varnish. The properties of this varnish are very similar to the properties of acrylic paints; therefore, it is better to apply this varnish on acrylic paints.

How to apply:

- The distance between the surface for painting and the nozzle should be no more than 20-25 cm, and the diameter of the nozzle should not be more than 1.8 mm;

- First, apply a thin layer of varnish;

- Then apply two wet coats with an interval of 5 minutes.

- And only then the layer of metallized lacquer should be applied last. When applying lacquer, it is necessary to increase the distance from the nozzle to the surface up to 30 cm in order to evenly distribute the metal particles.

Acrylic lacquer

This lacquer is obtained by refining petroleum products; this lacquer first appeared in 1958. This varnish is especially often used in the repair or painting of cars. When drying the solvent evaporates, and this is an excellent property for varnish.

Recommended article: How to repair a carburetor VAZ 2109Features of acrylic lacquer

Benefits:

- dries quickly even at room temperature;

- shines great.

Disadvantages:

- need to pour a lot of thinner;

- not enough good filling capacity;

- It is necessary to use several layers of varnish and a substrate of several types.

Mode of application:

- First you need to prime the surface;

- Apply about 5 layers of spray gun with an interval of up to 10 minutes, in order for the solvent to evaporate, if the solvent remains in the film, then it will interfere with the process of solidification;

- After 2 hours the film will harden.

- If you increase the temperature to + 60C, the drying process will be faster.

- Also, it is possible to make a polishing after 6 hours, if there was no additional heating, and if the heating was, then polishing can be done immediately after the surface has cooled down well.

Acrylic Polyurethane varnish

It is made on the basis of polyurethane mixtures and acrylic resins. If you add a hardener, then the drying rate of varnish will be much higher. It happens in the sale of acrylic polyurethane matt automotive varnish, as well as varnish with metal particles.

This varnish is used to create an opaque coating. Before work, in about 15 minutes a mixture of paint, hardener and thinner is prepared.

Mode of application:

- The first layer is applied thin binder coating;

- Then, at intervals of 10 minutes, two subsequent layers must be sprayed.

- Each layer must be dried for about 30 minutes at a temperature of + 60 ° C.

- Observe that the humidity does not exceed 75%. This requirement is relevant for any automotive varnish.

- The distance from the nozzle to the surface should be 20-25 cm, and the diameter of the nozzle should be 1.8 mm.

- It is possible to polish the surface to eliminate unevenness and trapped dust particles.

Polyurethane varnish

Polyurethane varnish является лидером продаж, его используют автолюбители и автопроизводители. Данный лак считается двухкомпонентным составом, он отлично подходит для покраски почти всех марок автомобилей. Для получения отличного состава необходимо смешать смолу, отвердитель и разбавитель.

Advantages:

- strong film that is highly resistant;

- great shine;

- not exposed to the environment and various chemicals;

- Easy to apply and dry quickly.

Disadvantages:

- to work with this varnish a temperature of at least + 20 ° C

- unacceptable increased air humidity;

Painting features:

- it is necessary to strictly adhere to the dosage specified by the manufacturer;

- Before applying the varnish, it is necessary to hardener, the resin with the dye to mix very carefully;

- for application it is better to use a pneumatic spray;

- It is important to keep the temperature below + 20C.

The technology of applying polyurethane varnish is about the same as when working with acrylic polyurethane varnish:

- apply a bonding layer;

- wait 15 minutes for the solvent to evaporate;

- apply a second coat.

- dry at 60 ° C in a drying chamber.

To apply varnish on the car with your own hands, you must:

- Carefully prepare the surface, completely cleaning it from dirt and dust.

- Do wet sanding with sandpaper No. 360. Use a regular sponge to maintain moisture.

- Put the car in a place where there is no dust.

- If necessary, cover the film with some parts of the machine that do not plan to varnish.

- Completely degrease the surface.

- Observe a distance of 25 cm from the nozzle to the surface.

- Spray varnish or crosswise.

- Multiple layers cover the entire required surface of the car.

- Between applying each layer wait about 10 minutes.

But it is important to know that if you apply a varnish on the surface with a thick layer, then it will stand out compared to other parts of the car that have been varnished with a thin layer.

Applying varnish on a car is a matter in which you cannot hurry. Therefore, if there is an opportunity, then it is better to entrust this process to professionals. But if there is to be a not very voluminous painting, then it is possible to paint everything yourself, the main thing is to select, stir and apply varnish on the surface to be painted.

Then a quick lesson about applying varnish: