>

Liquefied natural gas has always been cheaper than gasoline, and the difference in price is quite substantial, on average about two times. This makes many car owners to think about installing gas equipment, which allows to significantly reduce operating costs. The urgency of such a step in the current conditions is so great that it is not uncommon to see an elite class car refueling with propane-butane. What can we say about ordinary motorists? The payback of such equipment - from four months to a year, depending on the intensity of operation of the vehicle.

Gas equipment put in the car in order to save on fuel

However, this indicator also depends on other factors - for example, on the quality of components from which similar equipment is assembled. How to choose HBO to achieve significant savings without degrading the performance of the power unit? We will try to highlight in detail all the important details regarding the choice of the "right" gas equipment.

Generation HBO

As in any other field, gas equipment has a tendency to follow the spirit of technological progress. Manufacturers are constantly improving their products, focusing on improving security and improving compatibility with modern engines, which over time also become more and more complex.

There are currently five generations of gas equipment installed on motor vehicles:

- The first generation of the HBO appeared in the 70s of the last century, when carburetor engines were in use. Of course, almost half a century is a very impressive period, and in Western countries the equipment of the first generation can no longer be found. But, oddly enough, in our country, the park of carburetor cars is still huge, so, despite the inconsistency with modern environmental standards, this HBO is still running, to a large extent due to the low cost and ease of installation. Distinctive features of the 1st generation of gas-cylinder equipment are the use of a mechanical gas-type metering unit, vacuum gearboxes, the ability to install on carburetor and mono-injectors cars, the absence of feedback from the lambda probe.

- The second generation is, in fact, an improvement of the first without major changes in the design of equipment. The exception is the appearance of metering devices controlled by electronics, as well as the presence of feedback between the metering unit and the oxygen content sensor. This equipment meets the requirements of the Euro-1 environmental standard, while the first generation has long been banned for use in most countries.

- The third generation of HBO is compatible with the previous one by about 80%. Among the main changes, it is possible to note the presence of an embedded EBU, feedback with several sensors, except for a lambda probe (MAP, TPS, RPM), parallel gas injection, communication with the computer and the presence of a gas motor. For a number of reasons, this equipment is not imported to our country, but it can be found on vehicles imported from EU countries.

- The equipment of the fourth generation can now be called the most popular. In many ways, thanks to the introduction of a number of improvements in the design, making it more reliable, economical and safe. Among these innovations, we can highlight the possibility of a separate supply of propane-butane to each cylinder, work under control of modern ECUs, the ability to automatically switch the mode of operation (when one of the used fuels ends), compliance with environmental standards of Euro-3 standard, unification of connecting nodes / parts. In a word, such HBO is also easier to install, and easier to operate, and it is suitable for most injection vehicles.

- The main difference of the gas equipment of the fifth generation from its predecessor is the gas supply to the nozzles in a liquid form due to the use of a special gas pump. Due to the high cost, it is used much less frequently, mainly on Japanese-made cars of the latest generations, characterized by increased complexity.

Summarizing the above, you can simply remember which generation of HBO to choose for different types of cars: the best option for carburetor / mono-injectors cars will be HBO 1 - 2 generations, for modern injection models the equipment of the fourth generation will be the best choice - it is set to 80 - 90% of cases.

If you want to achieve maximum savings and minimum power loss - you should pay attention to the systems of the 5th generation, but be prepared for the fact that you have to pay a considerable amount for this.

Of course, the calculation of the economic feasibility of installing HBO should be the prevailing criterion. As practice shows, with an annual mileage of less than 10,000 km. Your savings will tend to zero, since the payback will be low, plus you should not forget about the annual maintenance costs, which we will discuss below. But if you are offered a HBO as a gift - you definitely should not refuse such an option.

HBO 4th generation

Since this equipment is the most massive, consider the features of its use.

Very often, cars with gasoline engines are equipped with gas equipment.

Although in our country it began to be used relatively recently, all over the world it is quite actively used to convert a vehicle to use propane-butane as a fuel instead of gasoline. Such equipment is highly versatile and can be used on most modern cars with an injection power plant, including turbocharged engines. Proper adjustment of HBO allows you to combine the work of these devices with self-diagnosis systems, which are equipped with all modern cars (OBD I / II, EOBD). Finally, the equipment of the fourth generation meets European standards for the emission of pollutants EURO-3/4.

We list the advantages thanks to which the 4th generation gas-cylinder installations still remain the most commonly used:

- relatively low cost;

- ease of installation;

- ease of maintenance;

- quite an extensive range.

However, this equipment has disadvantages that complicate its installation and use:

- an additional check is required every 10 thousand kilometers and, if necessary, adjustment (at a cost it is not so noticeable - about 300-700 rubles);

- not every master has enough qualifications to make precise adjustments to the equipment, which could guarantee the absence of failures in the operation of the power unit;

- the quality of the used liquefied gas is an important factor when using HBO of 4 generations, and the filters used do not always provide a solution to this problem;

- hoses that supply propane-butane to the injectors must be replaced periodically;

- This equipment does not guarantee the complete absence of gas odor.

Regarding how to choose the HBO on the car, there are two basic options for installation: buying a ready-made factory kit or installing a system assembled from various components.

In the first case, you get rid of the problem of selecting compatible components. Such companies as Prins, Vialle or Landi Srl offer kits, all components of which were thoroughly tested for teamwork, therefore all the technical characteristics of such systems are well known and “protected” in the ECU. Unfortunately, the cost of such equipment is high, so it is installed mainly in expensive cars.

The mass version is the assembly of a system of dissimilar components. And here comes the fore the knowledge and experience of the installer. The wrong injector or gearbox will inevitably affect the operation of all equipment as a whole. And it’s not even the fact that some masters deliberately use cheap components with obviously unimportant quality - many of them don’t even know that the same company may have a product line that is dramatically different in price and in functionality.

There is no need to go far for an example: STAG, a company specializing in the production of electronic control units, has an entry-level ECU (STAG 200), a standard range of “brains” Standart (STAG 4), an extended series (STAG 300 Plus) The premium class computer (STAG 300 Premium).

These, conditionally speaking, are completely different products, which differ even from the outside, but not every specialist in his practice came across representatives of all the above-mentioned series. Meanwhile, each unit has its limitations and disadvantages. In particular, STAG 4 must not be installed on vehicles manufactured after 2004.

Choosing a gearbox HBO

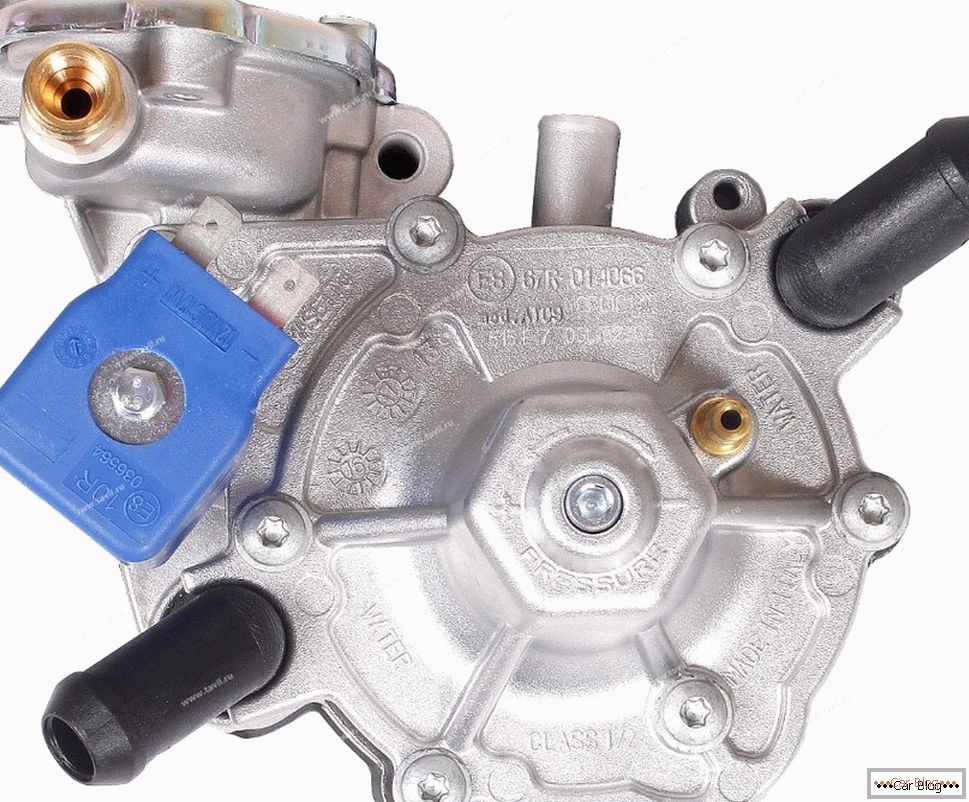

The main task facing this component of HBO is to convert liquefied propane-butane to gaseous form, as well as maintain the required level of pressure in the system. Before giving advice on which gearbox to choose for 4th generation HBO, consider those companies that can be found in domestic auto shops.

In the Russian market, the most popular brand that manufactures gearboxes for gas equipment of the 4th generation is the Italian company Tomasetto, which has three types of gearboxes in its product range: Basic (Normal), Alaska, Artic.

Their common features are a single-stage design, the presence of a protective solenoid valve and the filtering of a liquid (liquefied) gas form. Gearboxes from Tomasetto are characterized by the most attractive ratio of reliability to cost - this is a fairly high-quality and unpretentious to use products. A feature of its gearboxes can be called an interesting design of an emergency valve, which, when the critical pressure threshold (3.50 bar) is exceeded, is triggered by moving excess gas into an additional “unloading” chamber. At the same time propane enters the intake manifold, and the engine stalls due to an excess of fuel, closing the solenoid valve on the basis of feedback.

Proven Tomasetto Propane Reducer

Features line of gearboxes Tomasetto:

- Basic is characterized by the absence of additional heating of the fuel, so these gearboxes are recommended to be used on low-power power units (90 hp and less);

- Alaska gearboxes are equipped with a propane-butane gas heater and can be used for installation on cars with motors of 80 - 140 liters. with.;

- The Arctic series is equipped with another heater that works with gas in liquid form, such gearboxes can be built into the HBO cars with powerful engines (130 - 240 hp).

By installing an inexpensive gearbox on a vehicle with a capacity of 180 "horses", you will not be able to tune the HBO for the careful use of fuel, so this "savings" will result in you a complete lack of economic feasibility.

A characteristic feature of the Gurtner brand gearboxes is the unpretentiousness to the quality of the gas used, its own design of the emergency valve. The rest of the design of the gearbox vanishing with the products Tomasetto. Among the shortcomings, consumers note the "musicality" of the device, which does not always work silently.

HL-Propan gearboxes are compact in size due to the evaporator’s own design. Despite its small size, this device is capable of providing fuel to power units with a capacity of up to 230 - 250 liters. p., however, the relatively low resource and the occurrence of propane-butane in the cooling system caused a certain number of proclamations that slightly spoiled the brand image.

In their operational parameters, Shark gearboxes are in many ways similar to the Alaska analogue from Tomasetto, but they are equipped with a more spacious discharge chamber and provide a higher degree of gas heating, thereby eliminating the ingress of gas into the collector. This makes it easier to start the engine on gasoline after a long idle car.

Nozzles

Вне всякого сомнения, эта компонента любого газобаллонного оборудования является наиболее важной его частью. И если стоит вопрос, как выбрать HBO 4th generation, абсолютно соответствующее конкретной модели автомобиля и его силового агрегата, то в первую очередь обращают внимание именно на форсунки.

Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru Spray nozzles must be matched to the vehicle brand.

adom.ru Spray nozzles must be matched to the vehicle brand.

Many HBO installers do not even suspect the existence of special tables that indicate the type of nozzles for the make and model of the vehicle. As a result, it is not uncommon for vehicles with engines that require minimal fuel injection time (about 2 ms) when operating in certain modes are equipped with injectors with an injection time of 3 milliseconds or more. This means that when entering these modes, the nozzles will be constantly open, significantly increasing gas consumption and reducing the quality of the combustible mixture.

Therefore, the installation of cheap nozzles does not always contribute to the overall economy, and the skill of the master plays a crucial role here.

Оборудование под брендом Valtek как раз и относится к самым бюджетным и потому востребованным форсункам для HBO 4th generation. В частности, Valtek type 30 – это достаточно надёжные и нетребовательные к качеству пропан-бутана форсунки, обладающие хорошей ремонтопригодностью и не слишком точное дозирование горючего.

In the modification of Valtek type 34, this deficiency was eliminated, but at the expense of deteriorating maintainability and reducing the resource (up to 35 - 50 thousand km.).

Nozzles Matrix характеризуются повышенной точностью дозирования, но очень требовательны к качеству газа. Вернее, они боятся присутствия в газе масла, которое может попадать в пропан из насосов. В таких случаях двигатель будет работать неравномерно, но прочистка форсунок облегчается благодаря наличию специальных фильтров-отстойников.

A distinctive feature of Keihin nozzles is almost perfect metering accuracy, lack of irregularity in operation due to temperature differences, as well as omnivorous. The only disadvantage of this brand is its price.

The Barracuda nozzles from the Polish company Alex, at a fairly democratic cost, are characterized by good metering accuracy and resistance to the presence of pollution in the gas.

Another good brand with all the advantages of the products of a Japanese company at a more affordable price is Hana nozzles.

As you can see, the choice of the manufacturer of HBO is not a simple matter, and here you have to completely trust the specialist who makes the installation. Preference should be given to services that have long specialized in performing these operations and have a corresponding reputation.

HBO 5th generation

As noted above, for the most modern engines, which are characterized by increased complexity of design, the 5th generation gas equipment will be an ideal alternative to gas conversion. It is characterized by the following advantages:

- almost perfect match to the original injection parameters;

- low number of alterations during installation;

- increase the power of the power unit when switching to gas;

- complete absence of odors;

- no need for routine maintenance;

- stable working firmware, which ensures the operation of the injectors throughout the entire period of operation of the HBO.

The most revolutionary innovation of the fifth generation is the injection of propane-butane into the reservoir in the liquid phase, which provides the most acceptable fuel parameters (smaller volume and constant density at a constant energy potential).

Currently, such equipment is produced by the Dutch company Vialle, providing a corporate guarantee for HBO without limitation of mileage, but not too long in time (1 year). The manufacturer claims that the estimated resource of gas-cylinder equipment is up to 200 thousand kilometers, but there are frequent cases of vehicles with a mileage of about 350-400 thousand km entering Russia. with quite workable HBO.

Service HBO

If the problem of choosing a company producing gas equipment has already been solved, the installation itself is usually carried out during the working day. It should be borne in mind that the equipment responsible for the engine operation on gas, is characterized by its own set of routine maintenance. Maintenance HBO involves performing operations aimed at increasing the service life of the equipment. Ignoring these jobs can cause damage to both the actual gas supply to the engine and the power unit itself. And in this case, the cost of repair will be at least an order of magnitude higher. The main problem in our conditions is the low quality of gas. Due to this factor, the dirt accumulated by the internal surfaces of the gearbox and nozzles, causes a decrease in the amount of fuel supplied, leads to a significant loss of power and breakdowns of HBO components.

Maintenance of HBO increases its service life

Maintenance of automotive gas equipment involves the following work:

- computer diagnostics of the HBO electronic unit, which allows visualizing equipment performance and identifying problem areas;

- replacement of filter elements (filters of the liquid / vapor phase);

- health checks of electromagnetic valves, when detecting contaminations of shut-off elements - cleaning them using modern methods;

- cleaning nozzles (the need to perform this operation is detected at the stage of CD);

- pipeline purging;

- visual check of tightness of all connections.

It is believed that most of the pollution that accumulates in the filters, gives the reaction between propane and copper pipelines. However, in reality, other pollutants also enter the gas - for example, oils released during the transition of propane-butane to the vapor state. But these heavy fractions, falling into the combustion chamber, successfully and without consequences for the engine burn together with the fuel-air mixture. Resins and other mechanical impurities are filtered using a multi-stage system for cleaning HBO, however, the effectiveness of such cleaning cannot be called ideal.