It's no secret that a change in tire pressure leads to problems with the car. The decrease in pressure is accompanied by increased wear of the rubber, excessive fuel consumption. Increased pressure also does not lead to anything good: suspension wear increases, the body suffers.

And this is the minimum that can occur. Unregulated tire pressure can cause accidents and fatalities. Of course, we will immediately feel the immediate drop in pressure without any systems. But to prevent undesirable consequences and serves as a tire pressure monitoring system (TPMS).

There are various ways to measure pressure. They are divided into direct and indirect. An indirect method is the measurement using the ABS system. This method is based on measuring the speed of the wheels. The smaller the wheel diameter (which means that it has less air), the more speed it will do, unlike other wheels, which is indicated by the lamp on the control panel. But this method of qualitative, rather than quantitative, determination of deviations.

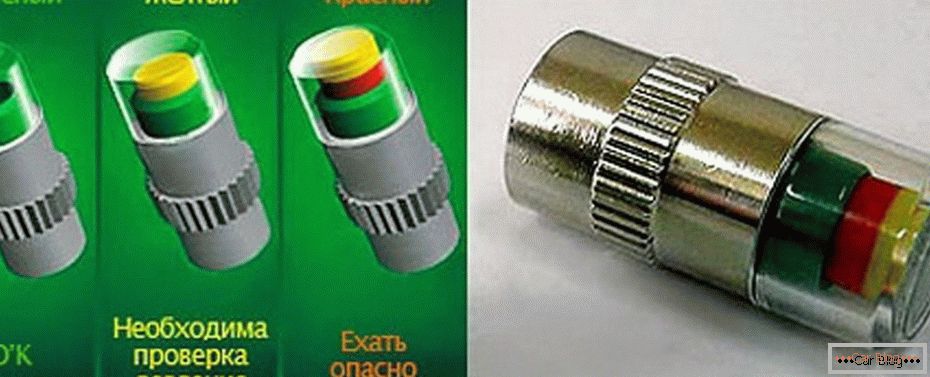

Direct methods of measuring tire pressure are considered more reliable. The oldest and simplest device is a pressure gauge. But while driving, you will not use it, and at each stop you will not run around the car, measuring the pressure. So, this method is used when there are problems with the electronics. A simple mechanical way to control pressure is to use caps with color indicators. You can install the caps yourself without much effort. Green color corresponds to two atmospheres, yellow - 1.7, red - 1.3 atmospheres. But this method is also far from accurate data.

Direct methods of measuring tire pressure are considered more reliable. The oldest and simplest device is a pressure gauge. But while driving, you will not use it, and at each stop you will not run around the car, measuring the pressure. So, this method is used when there are problems with the electronics. A simple mechanical way to control pressure is to use caps with color indicators. You can install the caps yourself without much effort. Green color corresponds to two atmospheres, yellow - 1.7, red - 1.3 atmospheres. But this method is also far from accurate data.

There are quantitative pressure control sensors. They are installed in the tires and transmit signals to the receiving device, which, in turn, is located either on the bottom of the car or on the wheel arch. After that, the signal goes to the control unit, where it is processed.

All data is sent to the display. Measurement frequency - once in 5 minutes in motion, once in 15 minutes when stopped. With such a system, we can immediately see the pressure deviations in quantitative equivalent.

All data is sent to the display. Measurement frequency - once in 5 minutes in motion, once in 15 minutes when stopped. With such a system, we can immediately see the pressure deviations in quantitative equivalent.

There are also sensors in the form of caps that transmit information to a special device or to the owner’s smartphone.