A great help in the garage is a handmade drum winch made with your own hands. It will be useful when moving oversized cargo, lifting weights, and even for pulling a car into an extreme situation. Such a device can be purchased at a building supermarket or auto shop, but a home-made manual winch will be designed to meet the individual needs of the user.

Content

- 1 The need for mechanized equipment

- 2 Variety of models

- 2.1 Lever view

- 2.2 Drum view

- 2.3 Assembly and traction type

- 3 The simplest imitation winch

- 4 How to make a winch with your own hands

- 5 Building the case

The need for mechanized equipment

There are no significant technical difficulties in the design. The operation of this device involves simple physical and mechanical laws. This allows the product to be widespread. The main advantages of most models are the following factors:

- compactness - comfortable dimensions make it possible to ensure mobility, since a small winch can always be taken with you, putting it in the trunk;

- ease of operation - to use the mechanism there is no need for a long time to deal with a simple design;

- mobility - the product can be used not only in the horizontal plane, pulling up something, but also vertically, for lifting from the ground;

- universality - the models are suitable for solving various tasks that may not be associated with the construction or repair;

- ease of repair and maintenance - stem from the design, which includes a minimum of elements and assemblies.

Even the one who has little knowledge of similar devices can deal with a homemade hand winch.

Variety of models

There are many variants of designs winches. They allow you to solve problems using convenient methods. The most popular are the three types of devices. They are designed for optimal load and are able to solve most of the current tasks.

Lever view

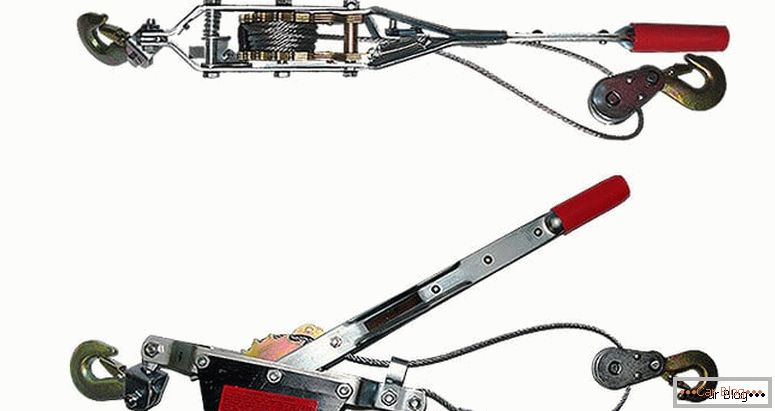

Equipped with a rope lever manual winch, made with his own hands, consists of the following elements:

- ratchet mechanism;

- steel rope;

- axis for winding the cable;

- powerful metal lever.

Its feature is the ability to work in limbo. This avoids in the frame the presence of a powerful base for fixing the product. Pendulum movements of the lever cause the ratchet to rotate, without unwinding the drum, as it is blocked by special clamps in the form of cams.

The disadvantage of the design is the relatively small length of the cable, which rarely exceeds 5-6 m. The advantages include the formation of significant traction. This figure is from 0.8 to 4 tons. The lifting height is limited to 4 meters when working in vertical mode.

See also: What gives the chip engine tuningDrum view

The design of this product consists of the following parts:

- basic support;

- gearbox;

- crank for rotation;

- drum;

- rope with hooks.

Built-in gearbox for the winch is selected worm or gear type. Often use toothed, as it wears less. However, the worm is able to withstand much greater loads.

In some sources, this model is called a cable, as it is equipped with a long steel rope. The principle of operation is as follows:

- the user rotates the L-shaped knob connected to the small gear;

- force is transmitted to the drum with a large gear;

- the cable is wound on the axis of the drum.

Thanks to the locking mechanism, it is possible to fix the mechanism in any position. The brake will also work with a sharp decrease in effort.

The drum type is able to withstand a load from 0.3 tons to 5 tons. With a permissible cable diameter of up to 15 mm and design features, it can be up to 40 m long. This allows not only to extract a car from a pit or swamp, but also to lift large stone or concrete blocks.

Assembly and traction type

There is no drum in the design of this manual winch. In fact, in its parameters it is in many respects similar to lever analogues. The body is equipped with cam clips, creating the required force.

The cams are parallel, so that the force on the steel cable is distributed on all sides approximately equally. This provides a longer life for the system. Lever provides cam locking. The winch has a traction arm, which is designed to protect against overload due to a cut pin.

This type of winch can be used in almost any field of business. More advanced design requires regular lubrication of working units.

Simple imitation winch

The most primitive, but at the same time effective version of the simplest winch consists of all-metal scrap 1.2–1.4 m long, a pipe 40-50 mm in diameter and a cable of the desired length. Scrap must be driven as deep as possible into the ground, as it will become the main axis of rotation in the system.

See also: Doing a spoiler with your own handsAbove the axis we put on the prepared pipe used as a lever. Thus, between the crowbar and the tube, an angle of about 90 degrees is formed. This ratio allows you to rotate the scheme. One end of the cable is attached to the scrap by a powerful carabiner, the second is fixed on the vehicle's drawbar.

The pipe helps wind the rope around the scrap. The longer it is, the less effort the user will have to apply.

How to make a winch with your own hands

To make your own design you will need the following set:

- a pair of gears with different number of teeth;

- shaft in the form of a nozzle for the winding axis;

- bushings;

- a pen;

- framework from a corner or a construction profile.

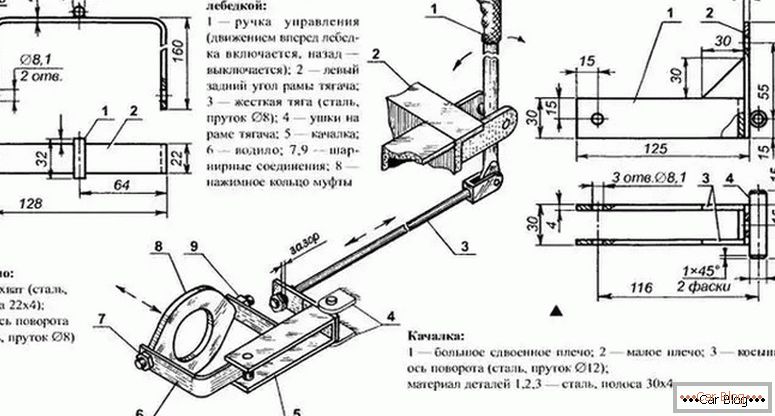

It is more convenient to use real dimensions from a prepared drawing or a sketch, drawn to scale.

The drive gear transfers the main force to the drive shaft. It is advisable to choose it with powerful teeth, providing the ability to transfer considerable effort. As the axial shaft, you can use the cut part of the cardan or other product, similar in size.

On the sides they use "cheeks" in the form of flat round pancakes. On the one hand, the driven gear coaxially fastens to them. Sleeves are used to ensure shaft slip. It is recommended not to put them on plain bearings, but to use rolling bearings, which will increase the endurance and durability of the structure. Also ensure the maintainability of the site.

In the manufacture of the case, it is necessary to ensure maximum alignment of the holes through which the gears will be placed. Drilling in this case is carried out after completion of the welding operations. The gear joint must rotate without jamming or slipping.

Housing assembly

The framework is formed of a channel or a corner. Sheet metal 4 mm thick can also be used. The phased algorithm includes the following actions:

- We cut a couple of channels to a length of 40 and 30 cm. A longer one will be on the right with a gear and a rotator.

- We carry out markup for through drilling.

- We make 4 holes for mounting the strap.

- Must be provided with holes for fixed mounting.

- We put on the driven gear on the shaft.

- Fasten plates with a triangular protrusion bolts to the gear.

- After landing gear fasten bushings.

- We put the shaft on channels.

In fact, the winch is ready. You can install it in any convenient place.