If the car is far from new, then the paint on it looks rather dim, so many car enthusiasts want to make their car as bright as possible so that it looks like new.

Of course, there are various detergents, as well as substances that give the car a shine, but they poorly cope with this task. Therefore, the only really effective means to give freshness to a car is polishing. After polishing the paintwork will be reliably protected, and the car will look brilliant.

For high-quality polishing requires good tools and quality materials. Polishing machines can be done at the station or with their own hands.

A variety of polishing machines and the principle of their action

Any polishing of the car does not do without a polishing machine, as an option, if there is a strong desire to save, you can use a drill, a grinder or just take a flat wooden bar and polish the body manually, but the result of all these handicraft actions will not be particularly impressive.

To be pleased with the result, you need to use a car grinding machine, it is also called polishing machine for cars, today there are a great many of them on the market, there are angle grinders and surface grinders. The working surface in surface grinding machines moves thanks to an eccentric, which is connected to the motor and makes circular motions.

In the newest surface grinding machines, the working surface can rotate clockwise and counterclockwise, such machines are called orbital. These machines, in most cases, are used to work on the putty surface, and for polishing almost never used.

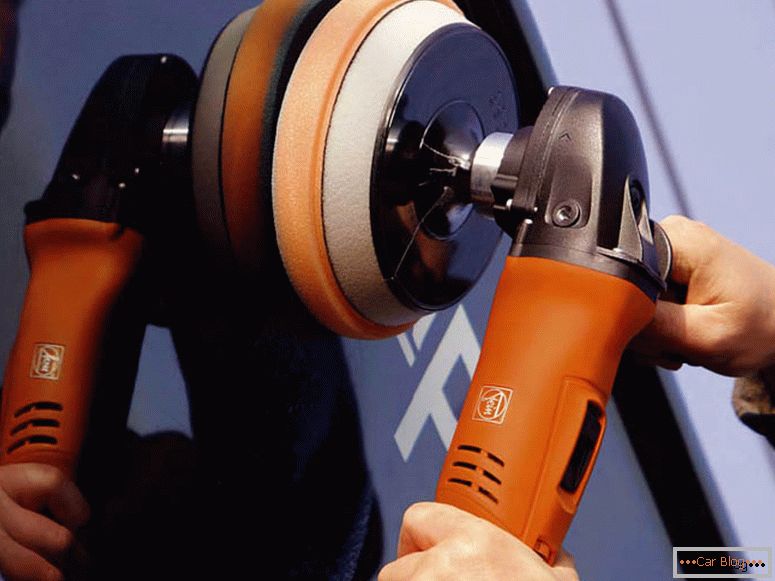

As for the angle grinders, it visually resembles a Bulgarian. To the main axis of the device at an angle of 90 degrees is a working shaft. What is characteristic of an angle polisher is that the gearbox has a higher gear ratio, so this grinder has a large torque and relatively low speed on the output shaft.

The principle of operation of polishing machines

Car polishers work on a fairly simple principle: the voltage is applied to the engine, which is located inside the housing, after which the rotor begins to rotate.

Through the gearbox, the rotational movement from the rotor shaft is transmitted to the output shaft of the grinder. On the working output shaft attached nozzle, it is also called the substrate or polishing disc. With this tape, polishers (fur or foam circles) are attached with Velcro.

Power polishing machines is different, so there are such types of machines:

- rechargeable;

- pneumatic;

- electrical (220 volts).

Advantages and disadvantages of these grinders

The main advantages of pneumatic machines are saving electricity and independence from the network. And the downside of such machines is the need for compressed air. It turns out that in the pneumatic network there must be air pressure necessary for the operation of the machine, and this is constant.

In addition, in order for the tool to serve for a long time, there is an air filter in front of the machine. By the way, without this filter, the manufacturer of pneumatic machines does not guarantee a long tool life. What is good about this filter is that it collects moisture and also adds oil to the air in order to better lubricate the rubbing parts of the machine.

Recommended article: Do-It-Yourself Tuning CaravanWhat else is inconvenient in working with pneumatic machines, so this is their fairly thick air hose. Therefore, in most cases, Grinders for car This type is used in large plants, and rather large service stations.

Rechargeable sander

This type of grinder allows you to polish the car body in the absence of electricity. But the battery will last for 15 minutes, so you have to stock up on spare batteries or do all the work in such a short time.

Angle Electric Grinder

For the treatment of the paintwork of the car should be used electric angle grinders, they are good because they are equipped with special nozzles that help to cope even with cleaning and grinding. Even angular polishing machines come in various modifications, and, produces them a considerable number of manufacturers.

When choosing a grinder that is important to pay attention

First of all, even before buying a sander, it is necessary to familiarize yourself with its characteristics, advantages and disadvantages. Usually, polishing machines are equipped with several types of working discs, which have different diameters.

Standard sizes are 125mm, 150mm and 180mm. The difference is that labor productivity will be higher if you use a larger diameter of the working surface. Therefore, for those who want to quickly finish with polishing their car, you need to use a larger working disc, whose diameter is 180 mm, if you can find an even larger size, you can safely buy it.

But there are certain nuances if working with an uneven surface, and for such a surface it will be inconvenient to work with a large diameter, for this and there are small sizes of the working disk. Unlike the large disk, the small one can crawl almost everywhere.

You also need to check which method of mounting the polishing attachment is used; there are several different mounting options:

- na lipučku;

- with ties and laces.

Depending on the features of the polishing machine, it is necessary to select consumables that are perfect for this type of attachment. For example, if in your typewriter the fastening is carried out with the help of a lace, and there is a desire to use circles of foam rubber, which are mounted on velcro, then it is necessary to purchase the “thrust bearing” for this purpose.

The speed of the grinder should also be adjusted, usually the speed should be kept in the range of 600-3000 rpm. If you adjust the speed correctly, the work will be performed better.

For example, there are polishing pastes with a large abrasive, for robots with them it is necessary to set the speed in the range of 900-1400 r / min. As for working with fine-grained pastes, which are usually used for final processing, the speed is recommended to set this: 2500-2900 r / min.

Grinding power

As in many other tools, power is considered a very important criterion, which affects the overall service life. The best option is a polishing machine, the power of which exceeds 1000 watts. Such power will allow this grinding machine to last much longer when compared with machines that have less power, and to operate them equally. Of course, the price of a more powerful typewriter will be higher.

Recommended article: How to increase the power of the engine VAZ 2109 (carburetor) do it yourselfIn order to install or remove the thrust bearing on polishing machines, it is necessary to lock the working shaft with a key or a special button on a typewriter. Therefore, before buying a polishing machine, make sure that there is such a button, because changing the thrust bearing on a typewriter with such a button is much easier than using a special key.

There are such grinding machines that have a function that fixes the trigger button. Such a function makes work easier, because there is no need to keep the start button all the time, and this is really very convenient. It also happens that there is an independent replacement of brushes in the typewriter, which is an additional advantage of such a machine, thanks to this chip, you will have to go to the service center much less often.

It is also desirable that the typewriter had a “smooth start”, which will eliminate the jerk at the start. Such jerks at the start create a temporary increased load on the network, sometimes even the machine knocks out, moreover, with a sharp start, polishing paste will splash in different directions, and this is very inconvenient.

Also, it is important to choose a machine with the ability to maintain a constant speed, even if the load changes. Grinders with this function allow you to get high quality polishing by maintaining the same number of revolutions despite the different efforts of the grinder to the polishing surface.

And most importantly, it is necessary purely for yourself to determine how the chosen machine will be convenient for you personally. The important thing is whether it is possible to adjust the handles, and you should also feel the comfort while holding such a machine.

Prices for polishing machines

Depending on what is required polishing machine, its price will be different, it depends on the availability of the above options and on the pathos of the brand.

As elsewhere, professional machines will cost more than amateur, but the more expensive the tool, the more reliable it will be and will provide a long service life. If the materials from which the machine is made are of high quality, the price will be higher, then such a machine will work longer, and if the machine is made of cheap materials, the price for it will be lower, but there is a risk that such a machine will break on the first day and this is not at all a pleasant situation. Therefore it is important to know what your goals are, because sometimes it is not necessary to buy an expensive tool for a small amount of work.

Prices for polishing machines are different: machines are considered “inexpensive” at a price of 20-100 American rubles, and high-quality appliances will cost between $ 200 and $ 500, but this will be a rather serious and reliable polishing technique.

Recommended article: A VAZ 2114 idling sensor costs about 350 rubles.Important Operating Tips

There are several stages of polishing the car body. The first step is pre-polishing, here the entire surface is polished, all contamination is thoroughly washed with special means.

The next step is roughing polishing paste with medium or large abrasive particles. This is followed by the last stage - the final one; at this stage the surface of the car body should be brought to brilliant shine when using fine-grained pastes.

The polishing process begins with the application of the paste to the surface that we are going to process, its size should not exceed 50x50 cm. We pre-set the speed on the machine within 1000 rpm for coarse-grained paste. After the process has started, the working disk should be pressed to the surface evenly, and also evenly move it over the polished surface. At the same time, it is necessary to control the force of pressure, because if you press unevenly, then the paintwork will be removed unevenly, and this will not lead to good.

If you create a very strong pressure, then you can erase the varnish, but as a rule, if you know the measure, then this will not happen. When polishing, the working area is heated, so it is also necessary to observe the temperature, because overheating will lead to cracks and peeling of varnish. To prevent overheating, you must not stop at one place and continue to polish the surface of the car.

It is imperative that when working with a polishing machine, you need to worry in advance about the working room, which will be reliably protected from dust and from the sun's rays. This is important because dust is considered an additional abrasive, as for the sun's rays, they slightly increase the overall temperature of the car body.

To get a high-quality polishing, it is necessary to monitor the speed of rotation of the working disk and the pressure. At the end of the polishing should reduce the pressing force, at the same time, the machine should be moved along the surface faster.

To check the quality of polishing, you must carefully inspect the finished surface, in addition, you can still pour some water on the newly polished body. If the work was done correctly, the water is divided into large drops and quickly flows. This indicator will say that the polishing is considered successful. This result is easy to achieve, if you follow the instructions that are in the manual for the use of a grinding machine. After the work done, the car will look like new.

Further video how to polish the car with a polishing machine: