Система питания автомобиля используется для подготовки топливной смеси. Она состоит из двух элементов: топлива и воздуха. Engine power system выполняет сразу несколько задач: очищение элементов смеси, получение смеси и ее подача к элементам двигателя. В зависимости от используемой системы питания автомобиля различается состав горючей смеси.

Types of power systems

There are the following types of engine power systems, differing in the place of formation of the mixture:

- inside the engine cylinders;

- outside the engine cylinders.

The fuel system of the car in the formation of a mixture outside the cylinder is divided into:

- carburetor fuel system

- using one nozzle (with mono injection)

- injector

Purpose and composition of the fuel mixture

For the smooth operation of the car engine requires a certain fuel mixture. It consists of air and fuel, mixed in a certain proportion. Each of these mixtures is characterized by the amount of air per unit of fuel (gasoline).

For an enriched mixture is characterized by the presence of 13-15 parts of air per part of the fuel. This mixture is fed at medium loads.

The rich mixture contains less than 13 parts of air. It is used for heavy loads. There is an increased consumption of gasoline.

The normal mixture is characterized by the presence of 15 parts of air per part of the fuel. The lean mixture contains 15-17 parts of air and is used for moderate loads. Provides economical fuel consumption. The poor mixture contains more than 17 parts of air.

Common power supply system

The engine power system has the following main parts:

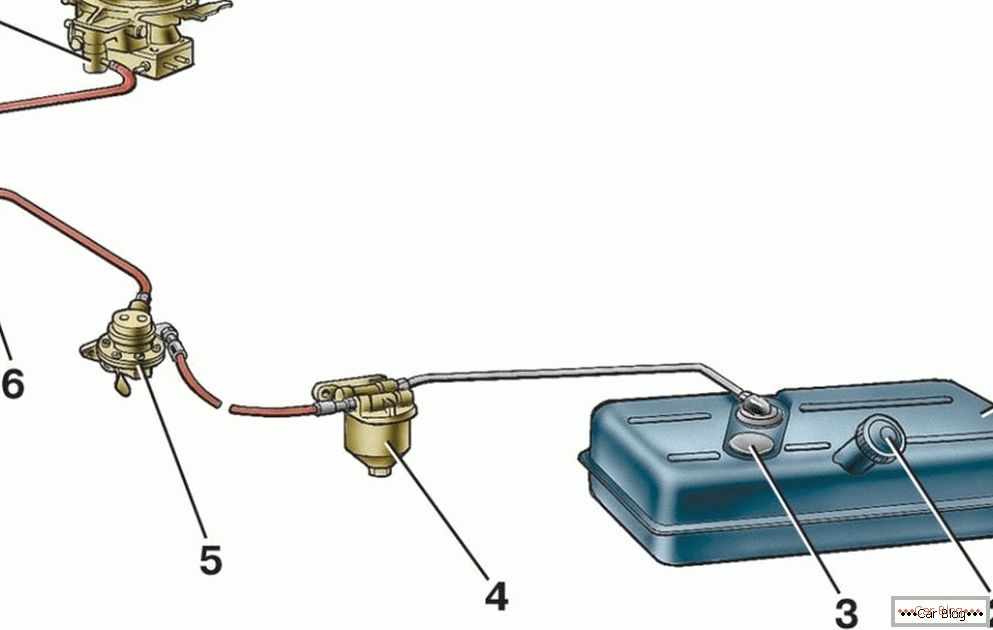

- fuel tank. It serves to store fuel, contains a pump for fuel injection, and sometimes a filter. Compact size

- fuel line. This device provides the flow of fuel in a special mixing device. Consists of various hoses and tubes

- mixing device. Designed to receive the fuel mixture and supply to the engine. Such devices can be injection system, single injection, carburetor

- control unit (for injectors). It consists of an electronic unit that controls the operation of the mixing system and signals the occurring malfunctions

- fuel pump. Required for fuel in the fuel line

- filters for cleaning. Needed to obtain pure mixture components

Carburetor fuel supply system

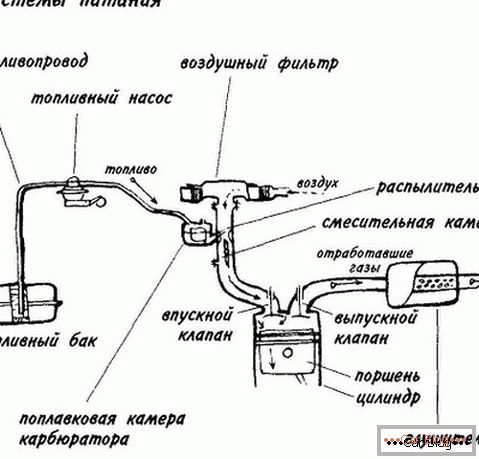

This system is distinguished by the fact that the mixing takes place in a special device - a carburetor. From it the mixture gets into the right concentration in the engine. The device of the engine power supply system contains the following elements: fuel tank, cleaning fuel filters, pump, air filter, two pipelines: intake and exhaust, carburetor.

The scheme of the engine power system is implemented as follows. The tank contains fuel that will be used to feed the internal combustion engine. It enters the carburetor through the fuel line. The feeding process can be implemented using a pump or naturally using a drift.

In order for the fuel feed to the carburetor chamber by gravity, it (the carburetor) must be placed below the fuel tank. Such a scheme is not always possible to implement in the car. But the use of the pump makes it possible not to depend on the position of the tank relative to the carburetor.

Fuel filter cleans fuel. Thanks to him, mechanical particles and water are removed from the fuel. Air enters the carburetor chamber through a special air filter that cleans it of dust particles. The chamber mixes two purified components of the mixture. Getting into the carburetor, the fuel enters the float chamber. And then it is sent to the mixing chamber, where it is combined with air. Through the throttle the mixture enters the intake manifold. From here she heads towards the cylinders.

After working the mixture, the gases from the cylinders are removed using an exhaust manifold. Further, from the collector, they are sent to the muffler, which suppresses their noise. From it they enter the atmosphere.

Details of the injection system

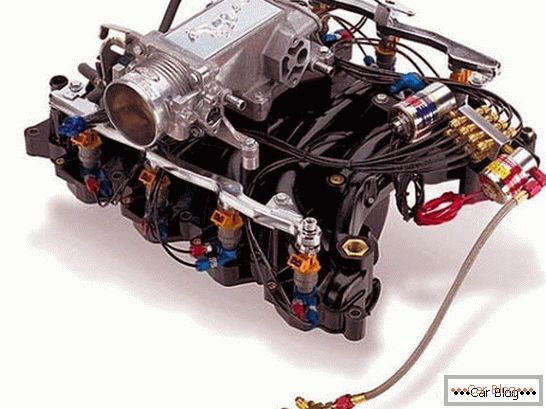

В конце прошлого столетия карбюраторные системы питания стали интенсивно заменяться новыми системами, работающими на инжекторах. И не просто так. Такое engine power system обладало рядом преимуществ: меньшая зависимость от свойств окружающей среды, экономная и надежная работа, выхлопы менее токсичны. Но у них есть недостаток – это высокая чувствительность к качеству бензина. Если этого не соблюдать, то могут возникнуть неполадки в работе некоторых элементов системы.

Recommended article: Transmission car. Automatic and mechanical. What is the difference?

«Инжектор» переводится с английского, как форсунка. Одноточечная (моновпрысковая) engine power system diagram выглядит так: топливо подается на форсунку. Электронный блок подает на нее сигналы, и форсунка открывается в нужный момент. Топливо направляется в камеру смесеобразования. Далее все происходит как в карбюраторной системе: образуется смесь. Затем она проходит впускной клапан и попадает в цилиндры двигателя.

The device power supply system of the engine, organized with the help of injectors, is as follows. This system is characterized by the presence of several nozzles. These devices receive signals from a special electronic unit and open. All of these injectors are connected to each other via a fuel line. It is always available fuel. Excess fuel is removed in the return line back to the tank.

An electric pump delivers fuel to the rail where overpressure is generated. The control unit sends a signal to the nozzles, and they open. The fuel is injected into the intake manifold. The air, passing the throttle node, falls there too. The resulting mixture enters the engine. The amount of mix required is controlled by opening the throttle. As soon as the injection stroke ends, the nozzles close again, the fuel supply stops.

Электронный блок является своеобразным «мозговым» элементом системы. Этот сложный механизм обрабатывает поступающие на него сигналы от различных датчиков. Так происходит управление всеми устройствами топливной системы. Такая engine power system diagram дает возможность водителю во время узнать о сбоях в работе, так как блок управления сигнализирует о них с помощью специальной лампы и кодов ошибки. Данные коды позволяют специалистам быстро выявить неполадки. Для этого им достаточно подключить внешнее диагностическое устройство, которое сможет распознать возникшие проблемы и назвать их.

Recommended article: 2005 Suzuki Grand Vitara in the secondary market