The injector is a revolution in the automotive industry. The mechanism itself is complex and for maximum performance its work should be well debugged. The fuel injection system of the engine works by means of an ECU (electronic control unit), which calculates the parameters of the fuel mixture before it is fed into the cylinders and controls the supply voltage to the ignition coil to create a spark. Injection units removed carburetor engines from production.

В карбюраторных устройствах задачу подачи исполняет механический эмулятор, что не совсем удобно, потому что его система не способна сформировывать оптимальную смесь при низких температурах, оборотах и старте двигателя. Использование компьютерного блока дало возможность максимально точно осуществлять расчет параметров, и беспрепятственно на любых оборотах и температуре подавать топливо, соблюдая при этом экологические стандарты. Минус наличия Abu в том, что если возникнут проблемы, например, слет прошивки, то мотор начнет работать либо с перебоями, либо вовсе откажется функционировать.

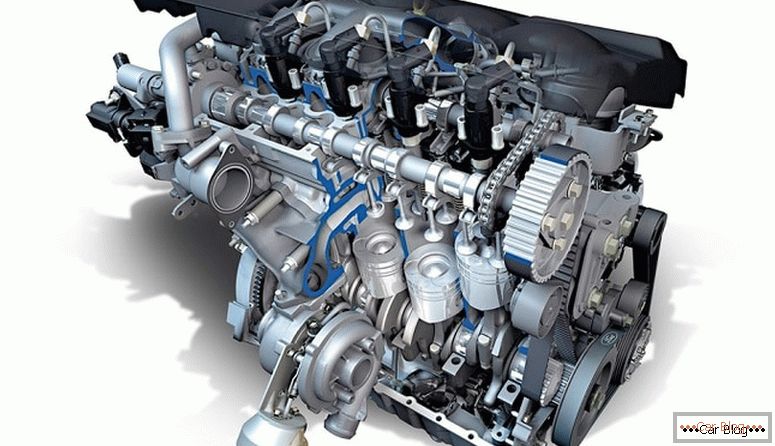

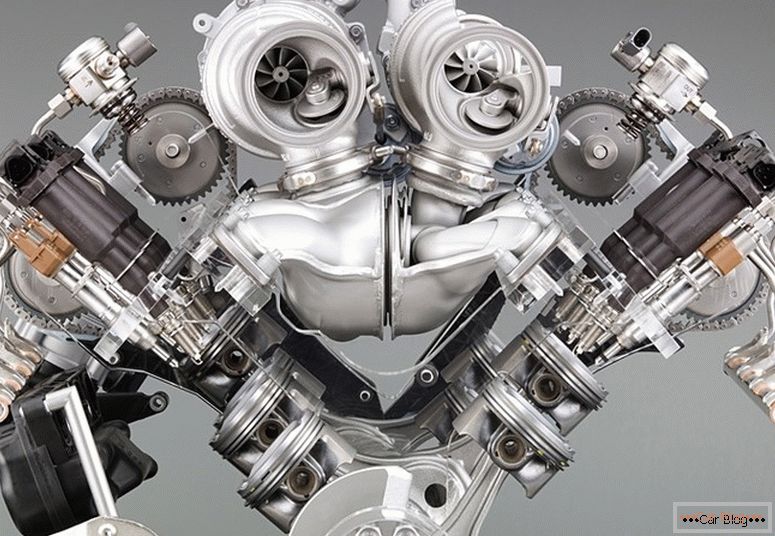

Injector engine

In general, the injection engine works on the same principle as the diesel one. The only difference is in the ignition device, which gives it 10% more power than the carburetor engine, which is not so much. Let the professionals argue about the pros and cons of the system, but every driver who plans to repair the engine with his own hand is required to know the injector device or at least have an idea of its structure. Also, with the knowledge of the injection unit, unscrupulous workers will not be able to fool you into the service station.

Content

- 1 The history of the injection system of injection

- 2 How does the injector work?

- 3 Electronic control unit

- 4 Location, classification and marking of injectors

- 5 Neutralizer / catalyst

- 6 Main sensors

- 7 Fuel supply system

The history of the injection system of injection

The injector is essentially an injector that acts as a fuel spray in engines. The first injection motor was made in 1916 Russian designers Stechkin and Mikulin. However, the fuel injection system in the automotive industry was implemented, there was only in 1951 West German company Bosch, which gave the two-contact motor simple mechanical injection design. I tried on the new Goliath minicar coupe “700 Sport” from Bremen.

After three years, the idea was picked up by a four-contact Mercedes-Benz 300 SL engine - the legendary “Wing of the Seagull” coupe. But, since there were no strict environmental requirements, the idea of injection was not claimed, and the composition of the elements of the combustion engines did not arouse interest. The main task at that time was to increase the power, so the composition of the mixture was made up with the calculation of the excess gasoline content. Thus, in the combustion products, in general, there was no oxygen, and the remaining unburned combustible formed harmful gases through incomplete combustion.

Injection engine installed

In an effort to increase power, the developers put accelerator pumps on carburetors that poured fuel into the manifold with each press of the accelerator pedal. Only at the end of the 60s of the 20th century the problem of environmental pollution with industrial waste has become a problem. Vehicles are in the lead among pollutants. It was decided for a normal life to radically restructure the design of the fuel system. It was then that they remembered for the injection system, which is much more efficient than ordinary carburetors. So, at the end of the 70th there was a massive replacement of carburetors with injection analogues, which were many times superior to operational characteristics. The test model was the Rambler Rebel sedan ("Rebel") of the 1957 model year. After the injector was included in the mass production of all global automakers.

How does the injector work?

Usually it has the following components in its construction:

- Abu.

- Nozzles.

- Sensors.

- Gasoline pump.

- Distributor.

- Pressure regulators.

If to describe briefly the principle of operation of the injector is as follows:

- the sensors receive signals about the system;

- after the block compares the parameters and controls the system;

- затем идет подача электрического разряда на nozzles, под его натиском они открываются, впуская смесь из топливной магистрали во впускной коллектор.

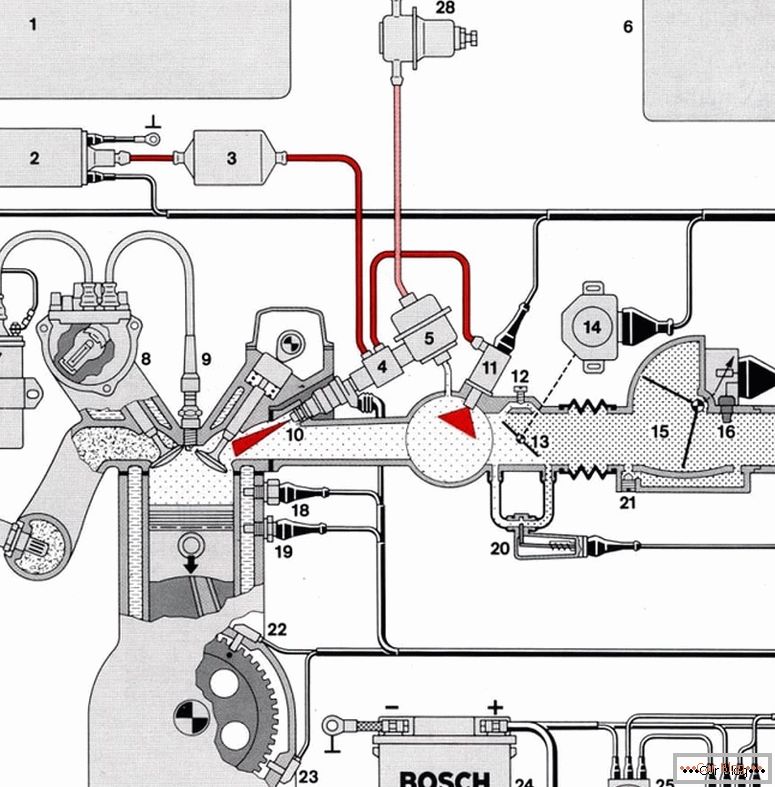

Injection motor circuit

Electronic control unit

Его задача беспрерывно анализировать поступающие параметры от датчиков и давать команды системами. Компьютер учитывает факторы внешней среды и особенности различных режимов работы двигателя, при которых происходит эксплуатация. В случае выявления несовпадений, центр подает команды исполнительным элементам для коррекции. Abu также имеет систему диагностики. Когда случается сбой, она распознает возникшие неполадки, оповещая водителя индикатором «CHECK ENGINE». Вся информация о диагностических кодах и ошибках хранится в центральном блоке.

There are 3 types of memory:

- Single programmable read-only memory (EPROM). Stores a common installation with a sequence of actions to manage the system. The storage chip is located in the panel on the unit board, it is easy to remove and replace with a new one. The information here does not change and is not erased in case of network failures.

- Operational Memory device (RAM). Acts as a temporary storage “notepad”, where the parameters are calculated and where the computer can make changes. The chip is located on the circuit board of the unit. For her work constantly need an electrical network, if the power is not received, then all data stored in the temporary storage is erased.

- Electrically programmable Memory device (Ezzu). Temporary storage of data and passwords of the vehicle anti-theft system. Memory is network independent. The codes stored in it are needed for comparison with the immobilizer codes, if there is no coincidence, the engine will not start.

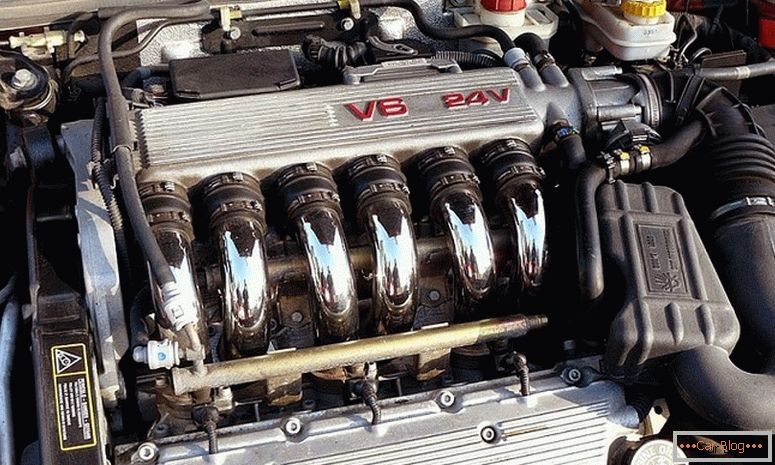

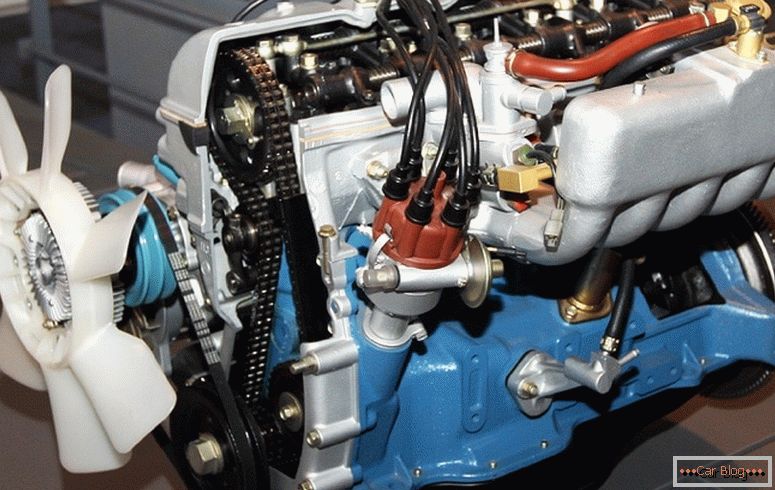

The first toyotovskiy injection engine M-E 1972

Nozzle location, classification and labeling

После разбора вопроса как работает инжектор, просмотрим поверхностно всю инжекторную систему. Инжекторная система, производит впрыск горючего во впускной коллектор и цилиндр мотора посредством nozzles, которая способна за секунду открываться и закрываться много раз. Система делится на два типа. Классификация зависит от расположения крепления nozzles, устройства ее работы и количества:

- monoinjection, иначе как центральный впрыск топлива Throttle body injection (TBI), работает посредством одной nozzles, подающей горючие в цилиндры мотора. Подача струи не синхронизирована ко времени открытия впускного клапана мотора. Одноточечный впрыск простой и мало содержит управляющей электроникой. Вся система TBI находится внутри впускного коллектора. Технология сегодня не популярна и почти не задействуется при производстве авто, так как не удовлетворяет нынешним требованиям.

- Distribution injection Fuel Multiport Fuel Injection (MFI) today in demand, because it is much perfect. Its essence is that each nozzle delivers fuel individually to each cylinder. Mounted construction outside the intake manifold. The signals are synchronized with the ignition sequence of the engine. This type of injection is more complicated in design, however, it is more powerful by 7–10% more economical than its predecessors.

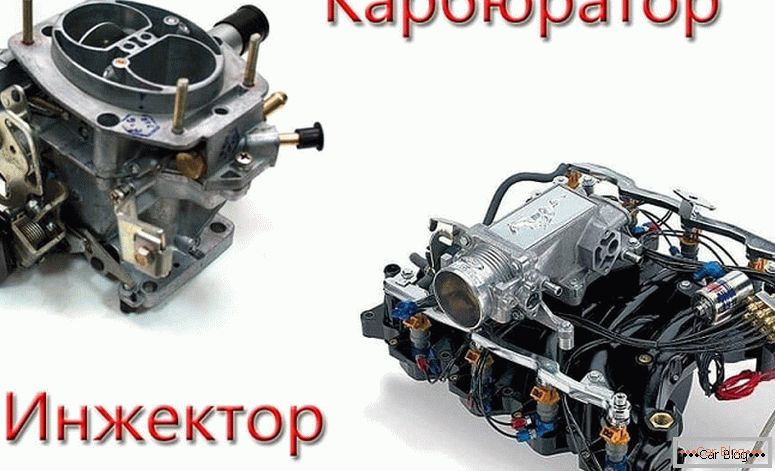

Comparison of the carburetor and injector

There are several classifications of distribution injection:

- simultaneous - the work of all the injectors is synchronous, that is, the injection goes immediately to all cylinders;

- pairwise parallel - when one opens before inlet, and the other before release;

- phased or two-stage mode - the injector opens just before the inlet. Gives the opportunity at low speeds, with a sharp pressing of the accelerator pedal to increase the torque of the engine. Injection takes place in two stages.

- direct (injection on the intake stroke) GDI (Gasoline Direct Injection) - the jet goes directly to the combustion chamber. For engines with this injection requires a higher quality fuel, where a small amount of sulfur and other chemical elements. GDI engine is able to regularly serve in the mode of combustion of super-lean fuel-air mixture. Less air content makes the composition less flammable. The fuel inside the cylinder arrives as a cloud near the spark plugs. The mixture is similar to the stoichiometric composition, which is highly flammable.

Инжекторные nozzles имеют разный способ подачи струи:

- Electro-hydraulic. Работает посредством разницы давления дизеля на поршень и форсунку. Когда клапан обесточен, иглу nozzles жидкостью придавливает к седлу. А если клапан открывается, то открывается и дроссель, после чего осуществляется заполнение дизелем топливной магистрали. Во время этого давление на поршень снижается, а на игле ничего не происходит, что ее и поднимает в момент впрыска.

Injector device

- Electromagnetic. На обмотку клапана поступает электрический разряд, контролируемый Abu. В итоге возникает электромагнитное поле наравне со сдавливанием пружины. Поле притягивает иглу и освобождает сопло для подачи струи. Пружина возвращается в прежнее положение после рассеивания электромагнитного поля, отправляя иглу на свое место.

- Piezoelectric. The most advanced type, used in diesel units. The speed of its actions exceeds the previous types four times, in addition, the amount of fuel injected is maximally verified. The actions of the injector are based on the principle of hydraulics, the work is carried out due to the pressure difference. First, the needle is on the saddle, then the current stretches the piezoelectric element, which begins to act on the plunger, which opens the valve for the movement of fuel into the line. Then the pressure drops, and the needle rises, carrying out the injection upwards.

Neutralizer / catalyst

To reduce emissions of carbon and nitrogen oxides, a catalytic converter was added to the injector. It converts hydrocarbon emissions from gases. It is used on injectors only with feedback. There is an oxygen sensor in front of the catalyst in the exhaust gases, otherwise it is called as a lambda probe. The controller, receiving information from the sensor, pulls the supply of the fuel mixture to the norm. The neutralizer has ceramic components with microchannels containing catalysts:

- two oxidizing platinum and palladium;

- one restorative from rhodium.

Fuel injection system

It is impossible that the engine with a neutralizer worked on leaded gasoline. This will disable not only neutralizers, but also oxygen concentration sensors.

Since simple catalytic converters are not enough, exhaust gas recirculation is used. It substantially removes the formed nitrogen oxides. In addition, an additional NO catalyst is installed for these purposes, since the EGR system is not able to create complete removal of NOx. There are two types of catalysts for lowering NOx emissions:

- Selective. Not picky about fuel quality.

- Cumulative type. Much more efficient, but very sensitive to high-sulfur fuels, which cannot be said about selective. Therefore, they are widely used in cars for countries with a small amount of sulfur in the fuel.

Main sensors

- Crankshaft position sensor (Hall Sensor). Allows the unit to know the location of the pistons in the cylinders. The essence of the work is that the gear wheel located on the motor shaft moves near the magnet. Its teeth distort the magnetic field, creating impulses in the coil. The computer reads these pulses and determines the position of the crankshaft. If this sensor is out of order, then the service station to get on your car will not work.

- Air flow sensor (ДРВ). Существует два вида таких датчиков, один измеряет массу другой объем вбираемого воздуха. ДМРВ производит замер и посылает в Abu. В потоке есть нагревательный элемент, температура которого автоматически держится на нужном показателе. Чем тяжелее воздух, тем больший ток должен проходить через него, для поддержания оптимальной температуры. Потому Abu по силе тока определяет массу всасываемого воздуха. Что касается датчика объёма (ДОРВ), то он устроен так. В потоке, где проходит забор воздуха, установлена перегородка, открывающаяся под натиском воздуха. Abu определяет положение заслонки при помощи потенциометра. Во время неполадки параметры датчика не учитываются, а расчет происходит по показателям аварийной таблицы.

Abu инжектора

- Throttle Position Sensor. Контролирует положение дроссельной заслонки, из-за чего Abu может правильно сокращать или увеличивать расход горючего.

- Sensors кислорода (лямбда-зонд). Вычисляет количество кислорода в выхлопных газах. На его показаниях Abu выявляет бедную смесь и вносит поправки.

- Coolant temperature sensor. It makes the computer understand when the motor has reached the desired operating temperature. At the time of the accident, the sensor parameters are ignored, the temperature is taken from the table based on the engine running time.

- Manifold Absolute Pressure Sensor (DBP) Analyzes the air and its amount in the intake manifold, this indicator is needed to establish the amount of energy conducted.

- Voltage sensor. Looks for the voltage of the on-board network of the machine. According to his testimony, the controller can add or, on the contrary, reduce idle speed of the motor.

- Knock sensor. It is a high-frequency microphone that detects unacceptable sound vibrations in the motor. Receiving abnormal sounds, the controller automatically adjusts the advance angle.

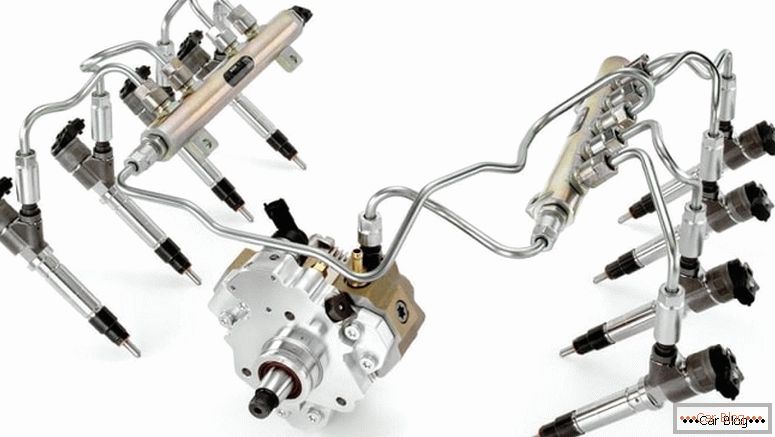

Fuel supply system

The node includes:

- fuel pump;

- fuel filter;

- fuel lines;

- ramp;

- nozzles;

- fuel pressure control.

Fuel supply system

Рассмотрим, как работает бензонасос на инжекторе. Насос находится в топливном баке и подает бензин на ramp под давлением 3,3–3,5 Мпа, что обеспечивает качественный распыл горючего по цилиндрам. Если обороты мотора увеличиваются, заметно возрастает и аппетит, то есть для сохранения давления, в ramp нужно поставлять больше бензина. Поэтому бензонасос по оповещению контроллера начинает ускорять вращения. Вовремя, прохода бензина к топливной рампе, лишнее убирается регулятором давления и спускается назад в бензобак, поддерживая тем самым постоянное давление в рампе.

The fuel filter is located under the body hood behind the fuel tank, it is mounted between the electric fuel pump and the fuel rail in the supply line. Its design does not understand, it is a metal case with a paper filter installation. There is a direct and reverse fuel line. The first is needed for fuel coming from the pump module to the rail. The second returns the excess fuel after the regulator back to the gas tank. The ramp is a hollow plate connected to nozzles, a pressure regulator and a system pressure control fitting. A regulator mounted on it controls the pressure inside it and in the intake pipe. Its design contains a diaphragm diaphragm valve and a spring pressed to the seat.