The amount of oxygen supplied to the fuel system is regulated by the throttle. At this moment it depends on its current state whether the mixture will be enriched or depleted.

Modern cars are additionally equipped with various sensors, on the basis of indications of which the electronics make adjustments to the process. This means that adjusting the throttle position sensor is a critical measure when setting up the correct operation of the fuel system.

Content

- 1 Operation of the sensor in the system

- 2 Adjustment work

- 3 causes of failure

- 4 Self-adjusting TPS in the garage

- 5 Sensor repairability

Operation of the sensor in the system

Throttle is used in engines for the correction of air supply to the intake manifold. Without oxygen coming with it, it is impossible to create the correct combustible mixture for burning it in the engine cylinders. The valve dispenses the volume, turning around its axis.

To improve the quality of the process is possible with the help of an electrical sensor. It encodes the current angular position of the flap into an electrical signal. Thus, the electronics reacts more thinly to the operation of the fuel system and to injection into the cylinders.

The signal from the sensor is transmitted to a special controller, in which information is generated about the degree of opening of the inlet channel. Based on the pulse feed rate, the force applied to the gas pedal is calculated. Ultimately, a portion of the fuel to supply to the system is determined.

Процедура отслеживания позиции заслонки начинается сразу после старта, а when ее степень открытия обеспечивает более 70…75%, в такой ситуации запускается продув силовой установки.

The sensor signals the transition to the maximum opening of the valve, the idle speed regulator begins to perform the controller commands, blowing additional oxygen into the channels, even past the valve.

The described work is performed due to the presence of a sensor, which is a device of potentiometric type. Approximate resistance in this design will be within 8 kΩ.

The first contact of the sensor accepts the reference voltage, and the second is connected to ground. For the central output, a variable state is provided, defining the current position of the flap. When applying 0.7 ... 0.8 V to the central channel, the electronics perceives the air passage to be closed. If the value of the voltage rises to 4 V, then the system responds to this, as with the full opening of the airflow opening.

The sensor is mounted outside the structure on a rotating axis. For its installation, a technological groove is provided, which allows fixing the element with the help of a pair of fixing hardware. Previously, a protective gasket in the form of a ring is put on the axle.

See also: Why the engine does not develop speed: possible causesПеред тем how to adjust the throttle position sensor, его не нужно снимать с посадочного диаметра. Все операции осуществляются без демонтажа.

Carrying out adjustment work

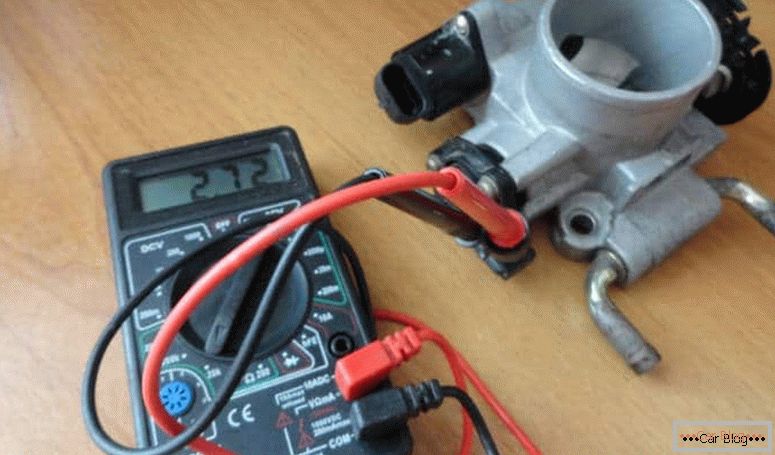

The test starts with the connection to the test connectors. For accuracy readings need to start the engine. Measurements are carried out on the signal contact. On the tester screen, these voltages should be no higher than 0.7 V. At the time of exceeding, you will need to reorient the sensor to the desired position. This is done by loosening the fixing bolts. Thus, the initial position of the sensor is tested.

During the test, turn off the connector and test the conductivity between the contacts of the device. The absence of control signals indicates that the sensor needs adjustment and adjustment.

Throttle clearance is also desirable to check. This is done by the probe, which should enter between the screw and the lever. In this zone, the voltage is measured with a multimeter. Its value should be zero. If present, it will be necessary to replace the sensor.

Turning the flap to the full opening, the current data and the final value are tested. Reference voltage parameters at the terminals are specified in the technical documentation for the device.

Reasons for failure

Proper operation of the device is the key to its long-term and productive work, as well as ensuring the effective functioning of adjacent systems. However, breakdowns also occur in unforeseen situations.

The most popular cause of failure of the DPDS is the natural wear of the mechanism. Technological spraying, which moves the slider, is erased due to mechanical stress. This leads to a distortion of the instrument readings. Also moving core fails.

The appearance of burrs is caused by damage to one of the tips. This is a consequence of the failure of mating elements. There is a decrease in the sensitivity of the contact pair of the slider and the resistive layer, and in some cases the contact disappears completely.

The driver is able to sense the need for repair by the following signals:

- floating idling speed must alert the car owner, because this may be the first signal;

- when engine stalls with sudden discharge of gas, you need to check the sensor;

- jerking when typing speedIn some cases, the situation is reminiscent of the lack of fuel for the engine; this is also a dangerous symptom.

It happens that while driving, the driver raises the speed to 2 ... 3 thousand rpm, and then releases the pedal. If the sensor does not work correctly, the speed is kept at a high level for a long time, sometimes even when switching to the neutral level. You will also need to test the sensor and with problems with the dynamics of the motor.

The most obvious signal of problems with the power plant is the presence of a lit "CHECK ENGINE" indicator on the dashboard. In such a situation will require mandatory computer diagnostics.

Independent adjustment of TPS in the garage

Adjusting work with the sensor does not depend on what design it has: contact or contactless. Initially, preparatory operations are performed. The corrugated pipe is folded back and its internal surface is washed with the help of suitable solvents, for example, with alcohol or gasoline.

The damper and the insides of the intake manifold are also cleaned of soot and dirt. Conducted a visual inspection of the entire site. In the absence of them we continue to work.

We weaken the fixing hardware on the sensor until it is possible to slightly scroll the part on the axis. We take out the barrier and return it to its place so that the sound of the impact can be heard. If not, then repeat the operation. After that, we loosen the fixing of the fastener on the sensor by turning the device case.

Install the sensor so that the incoming voltage smoothly changes during the opening of the valve. Work with sudden voltage drops is undesirable. After setting we twist the thread into position.

Sensor maintainability

A broken sensor is rarely repaired. The cost of the product in a few hundred rubles does not have to this. Also, not in all cases it will be possible to carry out the restoration, for example, when the surface spraying is worn.

Однако, есть ситуации, when повышается вероятность реанимации работоспособности. Сместив резистивные дорожки относительно ползунка, возможно продлить жизнь элекроприбору.

The sensor has a screw that locks the tracks in the desired position. To repair, weaken it, which will move the slider. This method will prolong the life of the node for a while. For contactless sensors, no repairs are provided even theoretically.