Full-fledged work of the main power sources in the car depends on the coherence of the whole mechanism. Even such an insignificant detail, as the weak tension of the belt on the generator, can disrupt the system. This applies to both domestic and foreign cars.

Consider the operation of the site on the example of the most popular car VAZ "Priora". In some cases, it is enough to carry out tightening with the help of a special mechanism in order to eliminate a weak fit between the pulley and the belt. If the production or extension exceeds the permissible parameters, then you will need to replace the alternator belt on the Priore. The operation can be performed independently in the garage.

Content

- 1 Problems with interference

- 2 Correct replacement

- 3 Need to replace

- 4 Replacement procedure

Problems with interference

The effective operation of the generator is capable of affecting not only the work of all electrical consumers in the car, but also the quality of battery charging. With a reduced level of return from the power generator, the battery is quickly reduced to full charge. Such an attitude to the battery will lead to its rapid failure, although a high-quality power source is able to operate effectively under favorable conditions for 3-5 years.

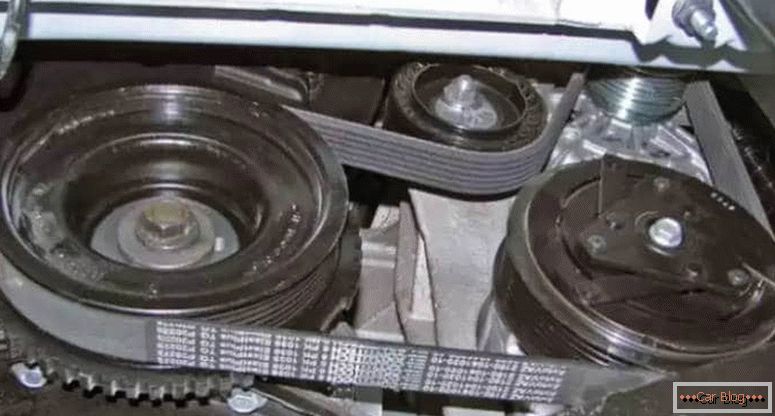

Rotation of the generator is provided by taking power from the crankshaft. This is done via a belt drive. The design provides that in addition to ensuring the rotation of the generator pulley, the same belt in the Prior simultaneously transmits rotation to the generator shaft and the pump of the hydraulic booster.

Therefore, before changing the alternator belt, it is worth considering the design features of the system. Trouble with interference in this node will be detected indirectly in other systems.

The geometrical parameters of the belt are directly dependent on his work with the rest of the power plant. In modern conditions, you can find a sufficiently large number of manufacturing companies offering such parts to consumers.

You need to know that the minimum length of the belt for the Priory generator is 742 cm, for cars using the hydraulic booster, this parameter is 1115 cm, and for cars with air conditioning installed the length of the generator belt should be 1125 cm.

When choosing this part in specialized stores, you need to take into account the minimum amount for the shortest copy. Before you replace the alternator belt, you should be concerned that the price for a 742-centimeter specimen should be at least 500 rubles. If you come across such parts at a base price, then this indicates a clear falsification of the goods.

See also: Evaluate the state of the engine by spark plugsCorrect replacement

The frequency of replacement is in direct proportion to the installed and processed equipment on the vehicle. If there is an air conditioner included in the system, the approximate mileage on one product is 45 ... 50 thousand km.

On the recommendation of the plant, it is necessary to carry out a replacement at least once every 60 thousand km. However, competent and caring motorists prefer to do this a little earlier, so as not to create unexpected problems. Accordingly, according to the time of operation replacement is carried out once in 2 ... 2.5 years.

Need to replace

Identify the need for replacement is possible by visual inspection. To do this, you need to regularly open the hood and observe the degree of wear of important parts, including the belt on the generator.

The obvious signs of the need to replace the alternator belt on the Priore are:

- visible mechanical wear, scuffs and gusts on the surface of the belt;

- traces of development on the outer surface;

- audible noise, whistling or hum of the belt during operation;

- insufficient tension on the maximum parameters of the belt tensioner adjustment.

You need to know that the belt deflection on the generator during a force of the order of 10 kgf and the deviation from the axis by 8 ... 10 mm is considered normal.

In order to ensure such measurement accuracy, it is sufficient to use classic bezmen, embedding or stretching the belt with the help of the belt on the test section to a value of 10 kg. At the same time, there should not be a deviation of more than 10 ... 12 mm on a serviceable belt.

During the measurement, the condition of the tensioning roller is tested. In the presence of backlash, you need to correct the measurement or eliminate the loosening of the axial parts of the tensioner.

To carry out operations with the tensioner, you can use a special key. His form is a handle with two axial cylinders located at a certain distance. A more rigid field method is to insert two bolts instead of axial elements, and further scrolling between them with a thick screwdriver.

You need to know that excessive tightening when adjusting affects the durability of the bearing, and a weak tension causes belt slippage on the pulleys.

Special lubricants help to provide high-quality matching to most of the belt mechanisms, including those on the Priore. They restore the condition of the rubber, extending the warranty period. The cost of one package does not exceed 300 rubles, while the lifetime is significantly increased.

See also: What is the cylinder head in a carReplacement procedure

Even a novice motorist will be able to perform the operation, it is enough to follow certain rules in the work. The algorithm consists in such actions:

- The vehicle is installed on a flat surface in a box or garage. The most comfortable condition will be the presence of a viewing pit under the car.

- Tensioners are retracted as much as possible to loosen the belt. A special wrench or a pair of bolts and a rigid screwdriver are involved in the procedure.

- The generator mount must also be loosened in order to move it from the operating point, ensuring the belt is removed from the pulley.

- The engine mounting bolts unscrew the mounting bolts to reduce the load in the area of the bracket.

- The motor is suspended with a jack on a hydraulic device or in a more comfortable way.

- We carry out the threading of the belt between the bracket and the pillow.

- A new belt is being mounted in place of the old one.

- We provide sufficient pressure on all sites.

It is mandatory to conduct control zatyag through several tens of kilometers. This will ensure efficient operation during the next period of operation of the power supply system.