To the brake system was always normal, you must constantly monitor its components. Since the brake pads work exclusively "for friction", they wear out faster than other parts. It is impossible to say exactly when the wear will occur, the conditional operational life of their work is from 8 to 15 tons of kilometers during normal driving without “recklessness”. Checking the brake pads allows you to approximately understand when to replace.

Brake system

Each transport is equipped with:

- brake mechanism;

- parking brake;

- spare brake. It is used in emergency cases when the main brakes fail. In cars, this is usually done by dividing the brake system into several circuits diagonally or front / rear.

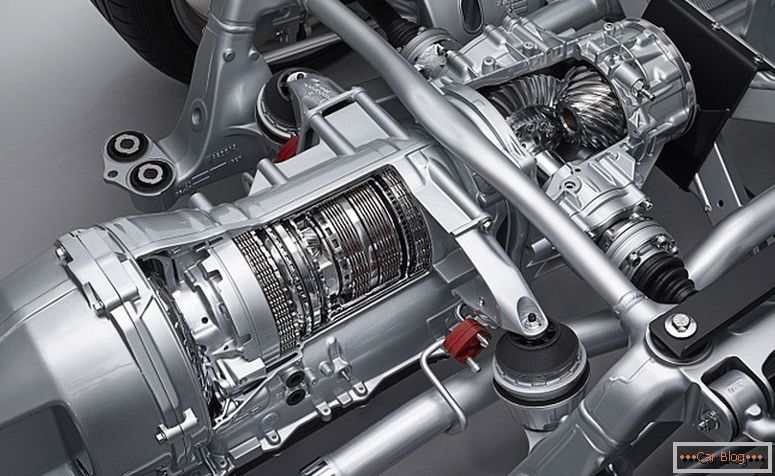

The brake system consists of a drive and braking mechanism with a drum or disc, as well as brake pads. Drum brakes are now used less frequently, although they last longer. Today, almost all machines have a disc brake device, such a system is considered fixed and has a caliper and two pads that are stable in one position. When the brake pedal is pressed, they squeeze the disc. There is also a system with a floating block, they are more complicated. During braking, the caliper piston touches one of them, it departs, leans against the disc and shifts it to the other, after which a clamp occurs.

Content

- 1 Major causes affecting wear rate

- 2 Signs of wear

- 3 Checking the pads without removing the wheel

- 4 The correct process of checking the pads and disc

- 5 Replacing the front brake pads

- 6 Replacing the rear brake pads

Main causes affecting wear rate

Тормозная колодка имеет две составляющие: каркас и фрикционную накладку. Если говорить коротко, то именно накладка выполняет основную задачу торможения, своим трением останавливая тормозной диск. Передние тормозные колодки изнашиваются в два—три раза быстрее задних. Все потому, что большая нагрузка во время торможения приходится на механизм передних колес, идет перераспределение weightа машины на переднюю ось. На скорости износа непосредственно отражаются:

- materialof which the parts are made. Each manufacturer sets its thickness to the product, so you need not to look at the price and purchase original linings;

- weight vehicle;

Pads

- sudden changes in temperature air;

- driving conditions. Sharp acceleration and emergency braking, of course, shorten the life of products;

- brake assembly design. If there was a failure in the cylinders, it will affect the pads.

It is noteworthy that in the winter season, the replacement is made less frequently, this suggests that in winter there are few maneuvers during the movement.

Signs of wear

Sometimes, just to assess the condition of the pads, to climb into the brake system is not necessary. Many are interested in how to check the brake pads without removing the wheels? Determination of wear can be the following features:

- When emergency braking occurs, a specific sound in the wheel occurs. This suggests that uneven wear of parts has occurred. Their plates have worn off and hit the brake discs, creating a creak. Similar noise is accompanied by wear on the disc.

- Pad wear sensor. Almost all current cars have indicators showing the state of the mechanism. The sensor looks like a lamp, when it is lit, it means it's time to change the lining. Sometimes oxidation of contacts occurs, and the indicator may simply not work, then wear will have to be determined visually.

- The system began to behave strangely at lower speeds. The level of brake fluid decreases, and the pedal is pressed gently, slightly pushing or, on the contrary, when pressed, the lock is activated.

The process of replacing brake pads

- Found metal chips on the disks, you need to go to the service station, as there was not only wear of the pads, but also wear on the disk.

- Long stopping distance.

Checking the pads without removing the wheel

It is easy to check the wear of the brake pads, especially when there are alloy wheels on the vehicle with large openings through which the brake assembly is visible. As a rule, only the outer block is visible. If you determine its thickness visually, then 1.5–2 millimeters is considered critical. When, even without removing the wheel, you noticed that the lining thickness is less than 5 millimeters - this is a reason for replacement. If the holes on the wheel are too small, and the brake mechanism is poorly visible, you need to start dismantling the wheel. When nothing prevents the review, it is easy to assess the state of the second lining and the brake disc in passing.

The correct process of checking the pads and disc

Before checking, see the table of indicators of permissible sizes of parts of the brake mechanism. When the data matches, start replacing. The process is divided into the following steps:

- We install the vehicle on a jack and remove the front wheel.

- Clean the disc from the settled dust.

- Caliper determine the thickness of the disk. Allowable wear parameter is 10.8 mm.

- In the viewing window determine the thickness of both pads, you can take the caliper.

- With a screwdriver we look how the pads go. When moving tight, it means they squeezed the disk. If the wear is uneven it is necessary to put a new cylinder and caliper.

- To get to the rear, remove the wheel and drum.

- We measure their thickness and size of the drum surface. The diameter should not exceed 201.5 mm.

Brake pads

Replacing parts is necessary if:

- lining in oil;

- products thinner than 1.5 mm;

- lining loosely connected to the base;

- discs must be replaced if there are scratches or deformation of the form.

Replacing the front brake pads

- We fix a car on a manual brake, we put barriers under wheels. All you need are keys number 13 and 17, as well as a screwdriver.

- We make dismantling of the wheel, in passing we check the level of brake fluid It must be between the MIN and MAX marks on the tank body.

- We press on the piston and pull the caliper until it stops.

- With the key on №13 we remove the bottom bolt, with the key №17 at this moment we hold the guide pin. Raise the body and pull out the pads. Eliminate dirt, if any.

- We put new products, springs are installed parallel to the top of the pads. Downward we withdraw the bracket body and fasten the bolt into place, after which we bend the barb of the lock washer.

- Install the wheel. Next, you need to repeatedly press the brake to check the piston.

Worn brake shoe

Replacing the rear brake pads

The replacement process is almost the same:

- Чтобы обездвижить авто ставим его на передачу. Включать ручник нельзя, так как он прижмет колодки к диску, и произweightти замену не получится. Для безопасности ставим бруски под колеса.

- We remove the wheel, we remove the guide pins with the key number 12.

- Remove the drum.

- Disconnect the pads from the spring.

- We take out the front shoe, remove the drive lever from the cable and remove it. Also done from the back.

- Now we are installing the new parts exactly the opposite.