In the proposed article we will try to reveal in detail all the main points of the question, how to check the compression in a car engine.

To obtain data on compression in cylinders will require the following tools:

- compressometer;

- syringe;

- candle key or key for injectors;

- 30 ml of conventional engine oil.

Measurement of engine compression should be done only after correct adjustment of the valve clearances, since this will significantly affect the final results of the study.

The main signs of low compression:

- reduction of engine thrust;

- increased fuel consumption;

- increased oil consumption;

- gray smoke comes out of the muffler.

All these are clear signs of severe wear on piston rings. The main cause of wear is burning to the piston and loss of elasticity.

Content

- 1 Check engine compression

- 2 Perform grinding valves

- 3 Oil diagnosis of piston rings

Check engine compression

The most accurate results when measuring compression can only be obtained using a compression gauge.

There are two ways you can use to measure compression:

- use of a compressometer (the most accurate procedure);

- manually (getting an approximate result).

To perform the second method, certain skills will be required, and there is nothing difficult in it. Before measuring engine compression, it is necessary to turn out all the candles except for the first cylinder and turn the engine crankshaft up to the moment when the compression stroke in the first cylinder is complete (this will be seen by the coincidence of the marks). Then in the other cylinders should alternately twist the spark plug and turn the crankshaft in the same way. By comparing the effort applied to crank the crankshaft, it is possible to determine which cylinder has reduced compression.

Of course, this is a fairly conventional measurement, which directly depends on the characteristics of human physiology. In such a situation it is better to use a compressometer. The optimal value of the compression is recorded in the technical passport of the car. In this case, the measurement of compression is carried out on a heated engine (approximately 80-85 ° C).

You must do the following:

- Start the car and warm up the engine to the desired temperature.

- Remove spark plugs.

- The next step will require third-party assistance. To perform the measurement it is necessary to ensure the opening of the throttle. The assistant must turn on the starter, fully depressing the accelerator pedal. Also, the opening of the throttle is provided by simply locking the gas pedal.

- Next, you should tightly install the tip of the compression gauge into the spark plug socket and once again make sure that the connection is secure.

- Now you can turn on the starter and crank the crankshaft until the pressure gauge stops growing (this procedure will take 2-3 seconds). The crankshaft should rotate at intervals of 100 rpm. This value is achieved only when the battery is working properly.

- Turn off the starter and look at the instrument readings. The measurement is carried out separately for each cylinder.

- After each measurement, remove air from the device or reset the data to its original position. If abnormality is detected, the measurement procedure on the cylinder must be repeated.

Compression levels may be low due to an incorrectly installed timing belt.

If the opportunity to learn the regulatory data is missing, then the normal rate of compression in engine cylinders can be calculated by the formula:

See also: How to repair a silencer without welding with tapeCompression (measured in kgf / cm2) = coefficient X * compression ratio

The value of the coefficient X is determined depending on the type of engine. For four-stroke engines with a spark ignition system, it is 1.2-1.3, and for a four-stroke diesel engine it is from 1.7 to 2. The degree of compression can be found in the technical description of the power unit.

Compression of a diesel engine or a gasoline engine of a new car should coincide with the data of the manufacturer or in the specified formula. The deviation of the compressometer between the cylinders must be less than 10% of the maximum value. Simply put, for a gasoline engine, the difference should not exceed 1kg / cm2. Reducing compression in the cylinder by 15% indicates a strong wear of the valves, failure of the piston rings, the piston or the cylinder itself. The subsequent operation of such a motor will only aggravate the situation.

Sometimes car compression can be restored. This procedure is possible when the cause of the loss of compression is an improperly assembled engine, the camshaft and the crankshaft are not initially installed according to the appropriate marks, when the teeth are torn off or there is a gap in the timing belt. In this case, the valve does not work in the right phase and does not fit snugly in the seat. This causes low compression. To correct the problem, you will need to partially disassemble the engine and grind in the valves and install the timing belt correctly.

We perform grinding in of valves

The maximum compression ratio can be achieved by lapping the valves. The procedure is carried out with a 15 cm long hose of the appropriate diameter. It is put on the end of the valve and performs the functions of a handle. If a special lapping paste is missing, then it is prepared on its own. Glass should be crushed in a metal mortar and add engine oil. The resulting mixture is applied to the edge of the valve and then start grinding. The paste should not fall on the rod, as this will damage the guide sleeve.

To improve the performance of compression, they resort to a valve lapping procedure.

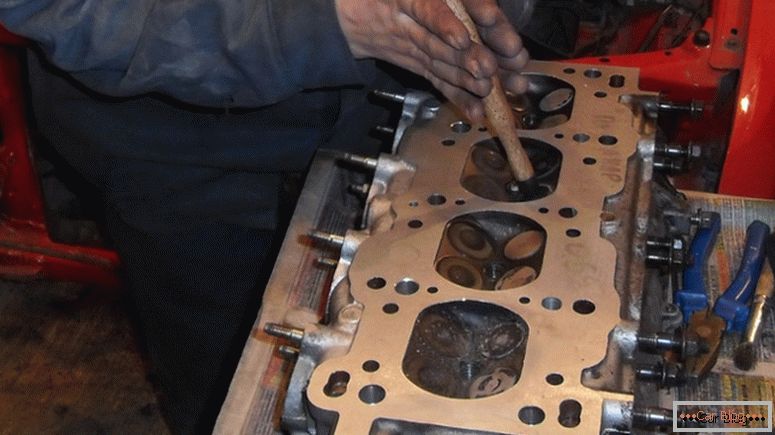

For convenience, the engine head is removed and placed on a horizontal surface. The hose-handle should be put on the valve stem. Next, the valve is pressed to the seat and begin to rotate, while periodically it must be rearranged to another position relative to the axis. This will help prevent circular risers on the valve and seat. Grinding in can be completed when a smooth path of 1.5-2 mm is visible on the valve surface. wide. At the final stage, the head and lapping areas are thoroughly washed with kerosene.

See also: How the car behaves if the lambda probe does not workOil diagnosis of piston rings

Compression in the engine cylinders depends on the degree of wear of the piston rings and the general condition of the power unit. There is another method to check the quality of the rings. This is the so-called "oil test". This method will require a syringe and regular engine oil. Approximately 10-30 ml should be injected into cylinders with reduced compression. oils. Next, close the candle hole and make a few revolutions of the crankshaft, which will allow the oil to fill the cylinder. After that, the compression is measured again. Indications before and after measurement must be compared.

Using a syringe and conventional engine oil, you can check the condition of the piston rings.

A significant increase in compression indicates wear of the cylinders, a failure of the piston rings or pistons. A slight increase in compression indicates leaking valves or damage to the gasket in the cylinder head. If the compression has not changed, it means that the valves are leaking.

Of course, it would be good to know how tight the cylinders are. However, without special equipment it is very difficult to determine. Therefore, the diagnosis of tightness of the cylinder and the head of the block is best done at the service station.