When repairing the engine, in particular, the cylinder head, it is necessary to do everything in such a way that there is no gap between the parts. Therefore, it is important to know how to properly grind the valve on the car. The work is very time consuming, monotonous, even boring. But on how well it is carried out, depends on the further operation of the engine. And if you have ever had to do this business, then you know what methods of lapping exist, the time and labor spent on them, and most importantly, how well they allow to carry out the work. But if you first heard about such a procedure, then you need to familiarize yourself with it in more detail.

Content

- 1 What is needed lapping

- 2 Manual grinding of valves

- 3 Lapping using a hand drill

- 4 Lapping using an electric drill

What is needed lapping

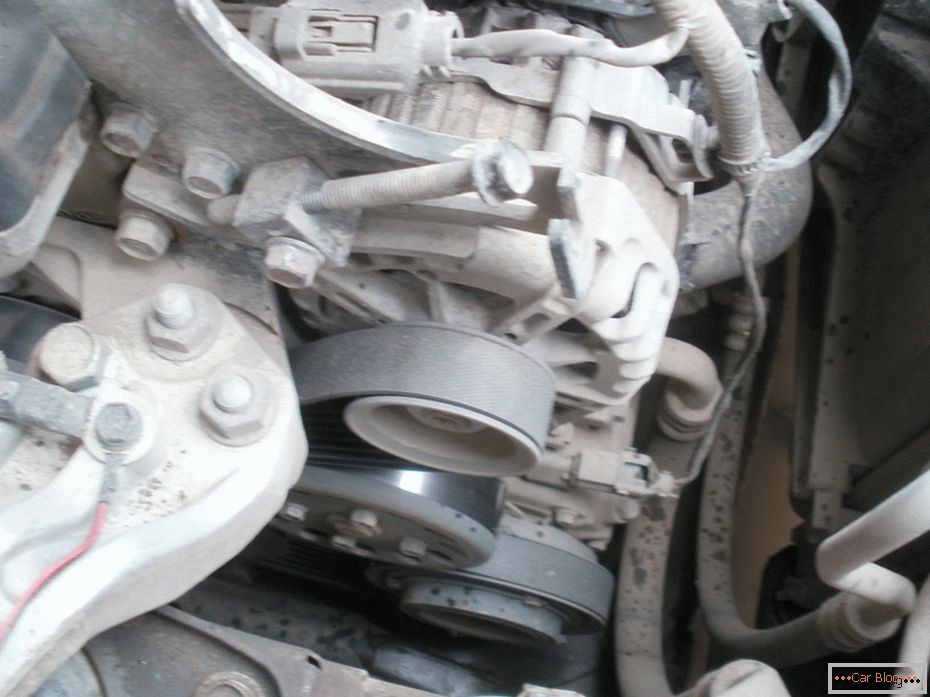

Manual valve lapping process

When buying a car, most look at the degree of compression in the cylinders. This parameter depends on a large number of factors, among which are the condition of pistons, rings, and valves. The latter can simply badly close the holes due to wear of the working surface or burning. A non-pressurized combustion chamber is the cause of low pressure in the cylinder. Appearance - performance deteriorates, acceleration becomes slow, the car simply “does not pull”, and with a large load, even a small incline becomes an almost insurmountable obstacle.

And if you have a major overhaul of the engine, and the compression in the cylinders is far from ideal, then first of all look at the valves, how well they close the intake and exhaust ports. On some models of cars installed a system that holds in the process of grinding. Everything is quite simple - the valve rotates around its axis, the excess metal is ground off and as a result a perfectly smooth surface is formed. When in contact with the unit, there are no gaps, the holes are closed as tightly as possible. But in most of the cars there are no such systems, so you have to do everything manually. There are only three methods, and we will consider them in detail.

See also: Why do you need a corrugation of the muffler and how to change itManual valve adjustment

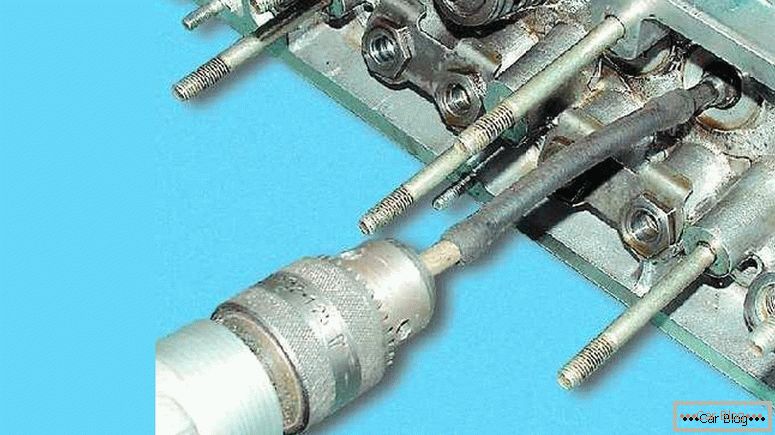

This device is used for manual grinding of valves.

Это самый сложный и трудоемкий способ, но он того стоит, ведь достигается максимальная точность. Вам потребуется valve lapping paste и специальное устройство. Последнее изготавливается из металлического стержня с зажимом на одной стороне, а рукоять Т-образной формы находится с другой. Паста – это смесь из абразива и мазута, в магазинах можно встретить ее под номерами 1 и 2. Цифра означает, насколько большой размер гранул абразивного материала.

The process can be divided into several stages:

- The valve is installed in the standard seat.

- The valve disc must be lubricated with paste.

- Put the device on the rod axis.

Далее lapping device поможет вам вращать клапан в разные стороны при помощи рукояти. Время от времени необходимо наносить слой пасты. И самое главное – старайтесь как можно сильнее прижимать рабочую поверхность клапана к седлу, чтобы провести притирку максимально качественно.

Lapping using a hand drill

During lapping, periodically you need to apply a new layer of paste.

This method will be much easier, and the quality is not particularly affected. And the usual hand drill with a reverse (this condition is obligatory) will help you with the work. You also need to make a special tool - a simple nozzle on the drill, which is shaped like a flat screwdriver. And stock up with coppers with a small slit under the tip of the nozzle in the center. When the entire tool is ready, you can proceed to the grinding.

Install the cylinder head upside down so that the nests are clearly visible from above. Lubricate the working surface of the valve being treated with an abrasive paste. Now, using bitumen, stick a pin on the valve plate. Wait a little for the bitumen to dry and set. Now take the drill with the nozzle, install it in the penny and start to rotate the valve. Add pasta as needed. Try to do so that the rotation takes place in both directions for approximately equal periods of time. To peel off the penny after lapping, it is enough to simply heat it.

See also: How to change the alternator belt on your ownLapping using an electric drill

The quickest way is to use a electric drill

But it will be much easier to grind with an electric drill. After all, you do not spend the force on the rotation of the handle. The method is very similar to the one that was described earlier. But it will be necessary to make a simple fixture of a rubber hose and an old valve. The hose will perform the function of the coupling, and the stem of the old valve will be clamped in the drill chuck. It is highly desirable that the inner diameter of the tube be equal to the diameter of the rod, so that the latter would enter it as closely as possible. To get rid of turning, you need to tighten all the joints of the tube and rods with clamps.

Обязательно наличие реверса, чтобы можно было поочередно вращать клапан в разные стороны, а также регулировку скорости. Таким способом lapping valves do it yourself займет немного времени, причем проведена она будет качественно. Но помните, что каждый клапан притирается под одно гнездо, ставить его в другое место нельзя. Пасту для притирки тоже следует использовать по номерам. Сначала №1, которая предназначена для первоначальной, черновой обработки, а уж затем паста под номером 2, необходимая для чистовой обработки поверхности. Когда ширина плоскости соприкосновения тарелки клапана с гнездом будет примерно 2 миллиметра, можно считать, что притирка прошла успешно. И самое важное в работе – не допускайте попадания пасты на стержень. После проведения работ обязательно промойте все поверхности растворителем или керосином, чтобы удалить следы пасты.