>

Although the first patents involving the creation of air suspension for automobiles began to be registered at the beginning of the last century, in practice these ideas could not be implemented for a long time. And only in 1955, the Citroen DS-19 was developed - a model that was completed with a standard air suspension with piston springs. Two years later, the American auto company Cadillac offered its own version - the Eldorado model, in which rubber cord pistons were used instead of telescopic springs. In 1961, the Mercedes-Benz 300 appeared, in which an air suspension was also installed as an option. A new round of popularity of adjustable suspensions comes in our time, when they began to be produced in tandem with electronic control units. In addition to the actual regulation of the clearance between the bottom of the car and the road surface, air springs allow you to get rid of such unpleasant phenomena as the longitudinal rolls of the car, the buildup in the transverse direction, subsidence and shaking. Modern air suspension allows you to use compressed air and for other noble purposes - tire inflation, installation of a pneumatic drive opening the trunk, etc. Not surprisingly, many advanced motorists are considering switching to this type of springs, but do not know which air suspension is better. This article will try to eliminate this gap.

Recommendations for choosing a pneumatic suspension.

Читать далее про то какую выбрать пневматическую подвеску-->

The principle of operation of the air suspension

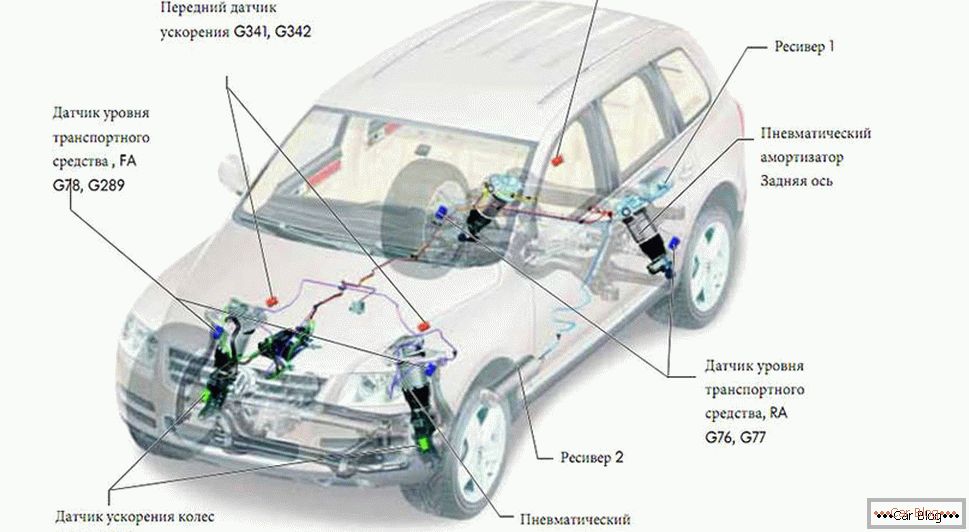

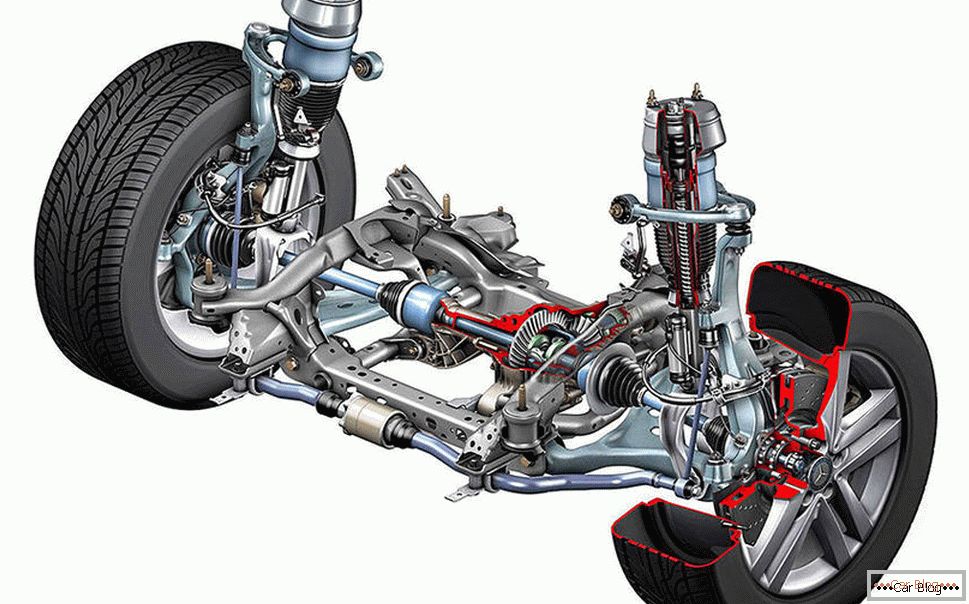

As the name implies, the pneumatic suspension differs from its counterparts of other types by the possibility of changing the level of the body relative to the roadway by using elastic elements of the pneumatic type. Among the cars of the last generation, the air suspension is optionally installed on some models of SUVs and elite-class cars (Audi Q7, VW Touareg). There are such cars and other well-known automakers - Bentley, BMW, Lexus, GM, Ford, Land Rover, Mercedes-Benz, SsangYong, Subaru. Essentially, the air spring is not an independent type of suspension, since technically it is part of the most common systems (multi-link suspension, McPherson design). With such undoubted advantages as increased permeability (increased clearance between the bottom and the ground), comfort, safety, air suspension is usually complemented by automatically adjustable shock absorbers. Such designs are called adaptive air suspension.

The schematic diagram of such a device includes four components:

- the actual elastic elements with pneumatic actuators, mounted on all wheels;

- receiver;

- air supply;

- electronic control system.

The main part of the suspension function rests on the elastic pneumatic element - it fixes the car body at a certain height above the road surface by maintaining the necessary pressure and the corresponding volume of air in the elastic pneumatic elements. Elastic pneumatic element is a structure consisting of a housing, a piston and a cuff. There are modifications in which the shock absorber is built in - such elastic elements are usually called air-resistant. The material of the cuff is a multi-layer elastomer of increased strength. The design of the elastic element can be supplemented by a pneumatic accumulator, as well as a residual pressure valve, designed to maintain the required pressure in the system in the presence of a leak. The purpose of the air supply is clear from the name - the supply of elastic pneumatic elements with atmospheric air. The module includes an electric motor, a compact compressor and an air dehumidification device.

The purpose of the receiver is to keep the volume of air necessary to maintain a given amount of ground clearance when driving at low speeds, without the need to operate the compressor. He is also responsible for maintaining the clearance while the vehicle is parked. Pneumatic with an air supply unit constitute a single structural element, called the pneumatic suspension system. There are two types of such devices: open or closed type. The latter are characterized by greater reliability (minimal air leakage), providing energy savings. Regulation of the required level of pressure is provided by the fourth component of the air suspension - an electronic control system. It includes various types of sensors, actuators and control electronics itself.

Sensors measure the following parameters:

- the amount of ground clearance;

- compressor temperature;

- acceleration of the car body;

- pressure level in the pneumatic system.

If necessary, you can also set the amount of clearance manually - for this there is a switch located on the dashboard. The control unit perceives the electrical signals from the sensors, interprets them and sends the appropriate control actions to the last element in the chain - the actuators. In the air suspension of the last generation, the control unit closely interacts with other vehicle systems (in particular, the system of course stability, control systems of the power unit).

The principle of air suspension

The air springs use three basic control algorithms:

- regulation of clearance in automatic mode;

- forced (manual) change of clearance;

- regulation of the level of the body in relation to the road surface automatically, but taking into account the speed of the vehicle.

The first mode works regardless of the load of the car - the sensors track the distance between the bottom and the wheels, keeping it constant. Manual change of clearance usually includes three modes: low, medium and high. The nominal clearance level is applied when driving at a speed of less than 100 km / h on roads with normal pavement. A lowered level is typical for high-speed driving, an increased level is when driving at low speeds (less than 40 km / h) or off-road. The stability of the vehicle while driving is provided by the appropriate mode of operation of the air suspension. The higher the speed - the lower the clearance is set by automatic, and vice versa. The use of shock absorbers with an adjustable level of damping allows you to change both the ground clearance and the stiffness of the air suspension, providing a more comfortable ride. We list the main pros and cons of air suspension.

Advantages:

- The main advantage of using a pneumatic suspension is the ability to maintain the necessary clearance regardless of the load on the vehicle. Air suspension allows you to control the position of the body with a very uneven loading.

- The second important advantage of the air spring is the ability to adjust the ground clearance depending on the driving conditions - this is important both when driving on high-speed highways, allowing you to reduce drag, improve directional stability, and when driving in conditions of increased comfort that when driving using an air suspension - also an important factor. We are talking about minimizing lateral rolls, about the smoothness of the car, about improved handling at high speeds.

- Reducing the load on the standard suspension system can significantly extend its life, reducing the cost of repair and replacement of springs and fasteners.

- Finally, the use of a pneumatic suspension allows you to drive a car with increased load capacity without degrading your handling.

The obvious advantages of air suspension are given for a reason, otherwise all cars would be equipped with these devices. Therefore, it is worth listing the factors that reduce the attractiveness of the air suspension for both carmakers and end-owners of vehicles:

- Very low maintainability. In fact, any failed node repair or restoration can not be, have to change it to a new one. It should also take into account the high cost of spare parts, and if you add about the same costs for repair or replacement services, you will have to think carefully before agreeing to buy a car with an adjustable air suspension.

- Another significant problem is the restrictions imposed on the use of such devices at low temperatures.

- Do not forget that the parts and components of the air suspension is very sensitive to dirt, dust, sand and other pollutants, so they need regular maintenance, which consists in cleaning equipment.

Considering Russian realities, installation of an air suspension on a car can be considered a good investment. And if you take care of it with due zeal, you will surely be satisfied with such an acquisition.

Types of air suspension

When choosing an air suspension you need to take into account many factors, including the current state of the vehicle's suspension system and your driving style. There are several types of air suspension:

- single circuit;

- equipped with two circuits;

- four-circuit air springs.

Single-circuit devices are structurally the simplest. They are installed on only one axle, so their use is limited to small commercial vehicles, including pickups. As a rule, single-suspension with pneumatic regulation are installed as an auxiliary element of the design. Dual-circuit devices can be installed on one or both axes, they can work independently or in conjunction. The main purpose of such devices is to increase the carrying capacity of the vehicle, as well as use in vehicles that periodically undergo uneven load distribution along the axes. The four-circuit air suspension is technically the most difficult, it can be installed on two axes and control all four pneumatic elements separately. Such a device is designed to accurately calibrate ground clearance and increase driving comfort.

Selection options

Consider the factors that should be paid attention to when choosing a particular model of air suspension.

Stand diameter

The fact is that the elastic elements are installed on the car in three different ways:

- using a separate fastening near regular racks;

- directly over the racks;

- in the place occupied by the springs.

If you use the second option, you must choose a suspension with a cuff diameter corresponding to the thickness of the rack. In particular, for domestic cars, including all modifications of the VAZ, pillows with a diameter of 52 mm are suitable. For foreign-made cars, the rack diameter in most cases lies in the range of 43–45 mm.

Installation dimensions

For small cars (VAZ, Daewoo), the best choice would be cushions having the following parameters in the unloaded condition: length - 190.0 mm., Diameter - 120.0 mm. Large passenger cars and jeeps should be equipped with air suspension with parameters 205.0 and 135.0, respectively. For small trucks and minibuses, pillows should be 245.0 mm or more in length. In diameter - from 150.0 mm.

Pneumatic rack height

This parameter is important for determining the amount of clearance. If the main purpose of the installation of this equipment is to reduce the load on the rear of the vehicle, you should choose an air suspension with the largest possible rack size in a non-inflated (normal) state. For jeeps, minibuses, the optimal length will be 285 - 320 mm., Providing the possibility of smooth movement with a large load on the rear axle and good cross-country ability when traveling over rough terrain. For small trucks should choose a pillow size of 370 - 420 mm. in normal (inflated) condition. For passenger cars with an extended base (minivans, station wagons) the length of the cushion should be between 225 - 250 mm. If you are aiming to make the car as low as possible (for example, in sports tuning), you should choose a device with a cushion of the shortest possible length in a compressed state measuring 80 to 100 mm The same air suspension is usually installed on sedans.

Installation location

Although two- and four-loop types can be installed on any axis, it is necessary to take into account some of the nuances regarding the installation site. Thus, it is better to install hose-type suspensions on the front axle, for example, if you want to give the car a sporty appearance with a raised rear part and a lowered nose. The shelves equipped with covers are the optimal choice for rear axle mounting. They are set to reduce the load on the back of a truck or a minibus with uneven loading.

Load capacity indicator by weight

Everything is more or less clear here: be guided by the data on your car and select the appropriate air suspension. For passenger cars it is about 1.2 tons, for jeeps - 2.0 tons, for minibuses - 3.0 tons, for small trucks - 5.0 tons.

Compatibility with compressor

Air suspension can be offered in different versions and trim levels, so this nuance must be taken into account. So, if the device is offered without a compressor, it will have to be purchased separately, making sure that it is compatible with the pillow in terms of the level of pressure maintained. The bottom bracket for most compressors starts at 1 bar, which usually causes no problems. But the upper limit may vary significantly, and there may be inconsistencies. The best option is to select a compressor that generates a pressure of 5 bar more than the pillows can withstand. In this case, the compressor will have time to redirect the excess air to the receiver, since permanent operation is harmful to it and can lead to failures. Since most air suspension models for passenger cars have a cushion designed for a pressure of 15 bar, the compressor power should be 20 bar. For a single-loop system, 7 bar should be supplied to each elastic element.

Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru

adom.ru

Receiver capacity

The correct choice of air suspension involves the use of a pneumatic airbag of a suitable capacity - it depends on how reliably the car will keep the necessary clearance when leaks appear in pneumatics. For passenger cars, a receiver with a volume of 8.0 liters is enough, for minibuses and off-road cars - 12.0 liters, for small-sized cargo vehicles - 15.0 - 20.0 liters.

Top manufacturers

It is important to buy air suspension from a reputable manufacturer - this guarantees high quality and durability of the system. The following companies make good air suspension:

- Airkraft;

- Airtech;

- Berkut;

- Blacktech;

- Camozzi;

- HornBlasters;

- Rubena.

The range of these manufacturers includes models with different characteristics, so when choosing a particular model, you should carefully examine its parameters, review the reviews and study the reviews on the thematic forums - relying on the recommendations of an employee of a commercial institution is not the best option.

What air suspension to choose

To summarize the above. For cars with small dimensions (for example, VAZ), the best choice would be a dual-circuit air suspension mounted on the front axle and having the following characteristics:

- cuff diameter (internal) - 52.0 mm .;

- external diameter - 120.0 - 135.0 mm .;

- size of compression - 90,0 mm .;

- capacity of the pneumocylinder - 4 - 6 l .;

- working pressure - 7 bar;

- load - 1200 kg.

For the average sedan to ensure maximum comfort when driving and the ability to adjust the clearance fit four-circuit system with sleeves and the following characteristics:

- cuff diameter (internal) - 45.0 mm .;

- size of compression - 90.0 - 100.0 mm .;

- height of pillows - 230.0 - 250.0 mm .;

- air capacity - 8 l.;

- working pressure - 15 bar;

- load - 2000 kg.

For jeeps and minibuses that require reinforcement of the suspension and reduce the load on the rear, you should choose a single-circuit pneumatic suspension mounted on the rear axle together with a standard suspension with the characteristics:

- cuff diameter - 150,0 mm .;

- size of compression - 90.0 - 100.0 mm .;

- height of pillows - 280.0 - 320.0 mm .;

- capacity of the pneumocylinder - 8 - 10 l .;

- load - 3000 kg.