Full preparation of the vehicle for winter conditions includes the replacement of rubber. Most often, wheels with built-in spikes are used for this purpose, providing increased stability and machine control on slippery surfaces.

Periodically there is a loss of individual metal elements, which adversely affects the operation of the vehicle. In such a situation, it will be necessary to restore the spikes on winter tires with your own hands in order to return the original properties to the ramps and not buy new wheels.

Content

- 1 base surface

- 2 Picking the right spikes

- 3 Special conditions

- 4 Piece wiring

- 5 Conclusion

Base surface

Independently install the spike should be exclusively in winter tires, prepared for this operation by the manufacturer. This is due to the presence of a more dense rubber material used in the manufacture of such wheels.

In autos you can find winter slopes with mounting holes, which allow the mounting of elements that increase the frictional properties of the wheels. This method is the most effective and practical. Also, young motorists are often interested in whether it is possible to restore the spikes on winter tires with their own hands, because the holes for them increased after the departure of the old spike. For this situation, special repair kits are used.

The formation of holes for spike occurs using special equipment, one of the components of which is a drill with adjustable speed.

Picking the right spikes

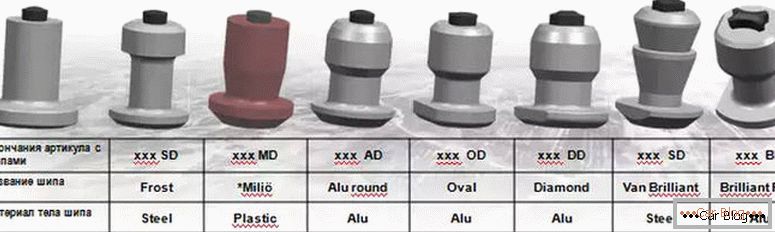

There are many types of inserts for winter tires. When choosing them, you will need to take into account more than one product characteristic. The distinctive features of thorns are:

- production material;

- geometric shape;

- departure parameter for the installation plane;

- combined or all-metal construction;

- estimated amount to be mounted on one wheel;

- power characteristics;

- mounting configuration.

The most common type of inserts consists of the body part (cup), which is in contact with the rubber layer of the wheel, and the core. Glasses made from a special plastic or metal. The material for the core may be as follows:

- steel alloy;

- Aluminium alloy;

- carbide substances;

- hard polymer.

Falling out of their seat occurs for various reasons, for example, a weak factory fit or a long ride on an asphalt road. After that, the loss of one or more elements is possible, and the landing nest subsequently increases.

The use of aluminum inserts is permissible for snowy or icy roads. When driving on an asphalt canvas, there will be a significant deformation.

One of the popular forms of steel inserts are diamond wheels. The name is taken solely because of the multi-faceted structure of the product; in this case, the material is used, not precious, but traditional.

Special conditions

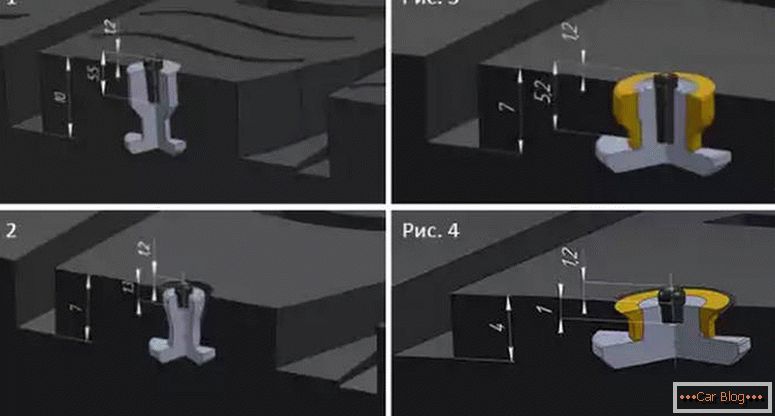

The correct choice of repair spikes should take into account the wear of the base surface of the tire, so the protrusion of the working head is usually 1.3 mm above the rubber.

When installing, you will need to comply with the norm, which regulates the number of metal elements in the amount of up to 60 pieces per linear wheel meter. In terms of the thirteen-inch slope, the maximum is 90 units, and for the sixteen-inch slope - a half hundred.

Piece wiring

Independent work will save about 40 ... 50 rubles for the repair of one spike. Such cost can be found at professional service stations.

To work in the garage, you can use one of the following methods:

- Manual method. The work allows the use of a special key to speed up the process; we also take a hammer, a screwdriver and a soap solution. This maximum budget option will suit almost any motorist. Its advantage is that the costs are only in the material.

- Semi-automatic operation. The spikes are screwed with a low-speed drill or a screwdriver with spetsnazadkoy. Productivity increases, however, you need to keep the spike in the correct position, so that he went into the hole without distortions.

- Automatic mode. To work you will need an air pistol. In its function it enters under high pressure to screw the material into the landing slot. The performance is maximum, but the disadvantage is the high cost of equipment, which does not pay off in single procedures.

When working in any way, a preliminary wetting of the wheel surface with a warm soap solution is carried out to facilitate installation. The pistol separator is filled with the necessary number of spikes. During the procedure, you will need to keep its working axis as perpendicular to the surface as possible.

See also: DIY Car RepairWith the manual method we carry out an independent marking of the points at which the installation is supposed. It is convenient to do this with white chalk or proofreader, which is sold in any office supply store. Using fine sandpaper, we clean the problem area, and with a short awl we design a hole. Having wetted the allocated site with soap solution, we carry out installation.

After fixing the spike in its hole, we measure the protrusion above the surface with a caliper, and if the value is overestimated by more than 1.5 mm, we plant it deeper. It is convenient to do this operation using an aluminum plate, pressing the top point through it.

The operation is repeated at each point. If any of the spikes entered unsuccessfully, then it must be removed with pliers.

Conclusion

It is necessary to take into account that for repair, in most cases, universal stud designs are used, having a radial working part. This type of product does its job, but the effectiveness, unlike the original version, is reduced by 10 ... 15% due to the lower possibility of adhesion to the coating.

After installation of the new elements, the wheel should remain at rest 10 ... 15 daysthat will provide maximum coverage of the surface in the nest. Even after installing the wheels on the car, the run-in period of 200 ... 300 km must pass, during which it is not advisable to exceed the speed of more than 80 km / h. Also at this time you should not use an intense driving style.

The average cost of a repair kit of 100 pieces is about 2000 rubles. Less quality batches from Asia for 500 pieces are offered at a price of 3,500 rubles. However, the service life of the latter will be lower. Refurbished wheel is usually efficiently operated for 2-3 seasons.