>

Front-wheel drive cars have a lot of advantages - in most cases, they are easier and easier to manufacture, and also have better maneuverability on slippery roads. However, they also have some drawbacks, for example, the use of the CV Joints in the drive system not only ensures uniform straight-line movement, but also causes sufficiently rapid wear of transmission components. To increase the reliability of these parts, it was necessary to develop a special lubricant, which somewhat improved the situation and increased the reliability of front-wheel drive cars. However, subsequently many types of lubricants appeared, which created confusion and caused some inconveniences for motorists. To eliminate them, we will answer the question what kind of lubricant for CV joints is better.

CV joints in the car require periodic lubrication

What are the challenges facing lubrication?

It is well known to any motorist that lubricants used in knots of a car serve not only to reduce friction and prevent premature wear of metal components. It should also reduce the load on the parts, which will ensure their free rotation and allow the vehicle to move forward unhindered. If we talk about lubricants for the CV joints, then, in addition to protection against friction, they also reduce the cost of fuel and transmission loss of the car.

Читать далее о том, какая смазка для ШРУСов лучше-->Второе важнейшее свойства смазки заключается в предотвращении распространения коррозии. Не секрет, что большинство поломок металлических деталей становится следствием полостной коррозии, которую также называют питтингом или крекинг-коррозией. В этом случае в ШРУСах образуются полости, называемые раковинами — при этом теряется эффективность передачи крутящего момента и появляется неприятный стук, который становится отчётливо заметным при повороте руля. Смазка призвана предотвратить распространение коррозионных процессов в ШРУСах, чтобы обеспечить их долговечность и уберечь автомобилиста от лишних затрат.

In addition, lubricants should be gentle on organic and synthetic polymers. Rubber or plastic anthers are always used to protect the CV joints, which prevent the ingress of contaminants from the outside. Grease should not dissolve the material from which they are made.

Varieties of grease

Over the long years of existence of front-wheel drive and four-wheel drive cars, dozens of types of trains for CV joints have been created. Practically all of them effectively cope with friction and reducing the loads that fall on transmission parts. However, many of them exhibit aggressive properties with respect to polymeric compounds or are not able to fight off abdominal corrosion. In the comparison of lubricants for CV joints, we will include only those compositions that meet all the requirements for them.

Lithium grease

The most popular lubricant for transmissions and other parts subjected to very high loads is made on the basis of a foamed solution of lithium in an organic acid. It is a yellowish grease with a high viscosity, which at a low temperature becomes even thicker and is difficult to spread on the parts. Lithium compounds for CV joints do a good job with friction and are able to reduce the loads that fall on the components of the drive mechanism several dozen times.

It is also worth noting their high conservation properties - lithium greases for the CV joints protect metal parts from moisture, neutralize dust and other pollutants that have accidentally got inside. However, not all compositions based on lithium are able to fight pitting of CV joints - therefore, experts recommend checking the drive system nodes after 50-60 thousand kilometers. One of the few exceptions is domestic grease Litol-24 - Russian car manufacturers allow its replacement in CV joints after 100 thousand kilometers.

Lithium compounds are resistant to most types of polymer coatings that are used in the production of anthers CV joints. However, some car manufacturers use modern high-strength plastics on an organic basis for the manufacture of such protective components - they can be dissolved by Litol and its analogues. In this case, you should pay attention to the instruction manual of the vehicle - it says what kind of lubricant is better to use to protect the CV joints from wear.

Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru

adom.ru

Currently, domestic manufacturers remain the world leaders in the production of lithium products for CV joints. Most foreign companies abandon them due to the emergence of new technologies that can provide better protection for transmission components exposed to high loads. However, the market still contains lithium grease for CV joints of the following brands:

- HASO;

- Very Lube;

- RENOLIT.

Molybdenum disulfide based lubricants

Despite the high efficiency of the lithium-based CV joints, the experts focused on finding a new solution that would be ideal for all cars. The result of their research was a new generation of lubricants, in which a compound such as molybdenum disulfide was added. The main difference between such compositions for CV joints was increased resistance to corrosion. The reports of the experts who carried out the life tests stated that even after 100 thousand kilometers the CV joints did not show signs of serious wear. However, such a lubricant is not eternal - even under ideal operating conditions, it is recommended to change it every 90–100 thousand kilometers or 5 years after the primary packing of the unit.

The effectiveness of the fight against friction in materials for CV joints based on molybdenum disulfide was as high as in lithium analogues. In addition, a decrease in the content of organic acids, substituted with a metal salt, led to a decrease in aggressiveness with respect to any polymer surfaces. Lubricants for CV joints based on molybdenum disulfide can be used in almost all modern cars - this recommendation is given by manufacturers.

However, funds based on molybdenum disulfide have one significant disadvantage - it is afraid of moisture getting into the CV joint in violation of the tightness of the anther. The consequence of such minor damage can be a complete loss of lubricant of its properties, which will cause the destruction of the site. Therefore, when using lubricants from such a group, it is better to carefully check the condition of the anthers every month, as well as after driving off-road or after strong blows that hit the front of the vehicle bottom.

To understand which lubricant with molybdenum disulfide is better, you should not pay attention to the cost of such products. It often turns out that a reasonably cheap option has better efficacy in the fight against friction and cavity corrosion. A good example is domestic lubricants, which are produced under the general name of CV JOINT-4 - they contain a sufficiently large amount of molybdenum disulfide and effectively protect transmission components from any external influences. From foreign analogues, we can recommend the compositions for CV joints of the following manufacturers:

- BP;

- Liqui Moly;

- Texaco;

- Car;

- IT.

Бариевые смазки

Recently, a lot of alternative lubricants have been created, which are intended to protect CV joints from wear and various external influences. However, most of them are not widely spread due to low efficiency or high cost of such funds. The only exception was barium grease, which can be a real alternative to materials based on lithium and molybdenum disulfide.

Its main advantage is increased resistance to moisture - for example, after the rupture of the CV joint boot, it is not necessary to change the barium lubricant if it has not accumulated a large amount of polluting materials. In addition, the barium composition is able to deal with all types of corrosion, preventing premature failure of CV joints, even when operating a vehicle in particularly aggressive conditions. The advantage of barium-based compounds can be called a completely neutral chemical composition with respect to any polymers - it does not destroy the anthers and does not contribute to the loss of elasticity of various seals.

Of course, such means for CV joints are still poorly distributed due to their high cost and complexity of manufacturing. For example, the only domestic barium-based product is lubricant ShRB-4. Instead, you can buy lubricants for CV joints of foreign manufacturers, but in this case you will have to prepare for high costs. Also, a significant disadvantage of the described lubricant is low resistance to low temperatures - therefore, with the active operation of the car, it is recommended to replace the lubricant in the CV joints and conduct their complex diagnostics.

What lubricant should not be used?

Very often, car owners fall victim to the marketing moves of sellers of automotive goods - they argue that it is their products that will guarantee the reliability and safety of the vehicle, although in reality the situation is completely opposite. For example, do not use graphite grease to protect CV joints, as it is designed to protect bearings and other movable joints of electric motors. Before buying a graphite lubricant, it should be understood that the service life of CV joints with it will be no more than 20-25 thousand kilometers. It is worth being especially careful when ordering the replacement of grease in the garage service - they often use low-quality materials or materials that do not meet all the requirements.

In addition, you should not purchase hydrocarbon products, including technical petrolatum, despite the fact that their packaging may contain information about the possibility of processing the CV joints. The reason for this is the conservation nature of the hydrocarbon composition. They perfectly withstand the effects of moisture, do not allow corrosion and damage by foreign pollutants, but they begin to deteriorate after reaching a temperature of 45 degrees. It is clear that in such high-loaded transmission nodes as CV joints, the temperature will be much higher, which will lead to the complete leaching of lubricant after a few kilometers. The use of technical petrolatum and other hydrocarbon agents to protect CV joints can only lead to their breakdown after a very short period of time.

Also, the rapid composition of SHRUS can contribute to the consistent compositions, based on sodium or calcium. They are used in assembling various components of automobiles, including bearings, moving joints, drive cables, but they are completely unsuitable for work in heavily loaded assemblies, examples of which are front-wheel drive CV joints. The worst consequence of their use may be the accelerated spread of corrosion - the result will not take long to wait and after 15-30 thousand kilometers the CV joints will become completely unsuitable for further operation. Among the lubricants containing mineral components, and prohibited for use in the transmission of the car, you can also call compounds based on iron and zinc.

Rules for the replacement of grease in CV joints

To gain access to CV joints, you will have to pre-disassemble the chassis of the car. You will need to remove the ball bearings and thrust, which support the CV joints, if any, in the car. Before pulling the part, carefully inspect the front suspension - it is possible that there are still some parts in it that will damage the CV joints when trying to remove them. After that, you need to remove the ties, which hold the inner part of the CV joint and take the shock absorber racks - it will be enough to make a little effort to get the part in your hands.

It will take disassembly of the chassis

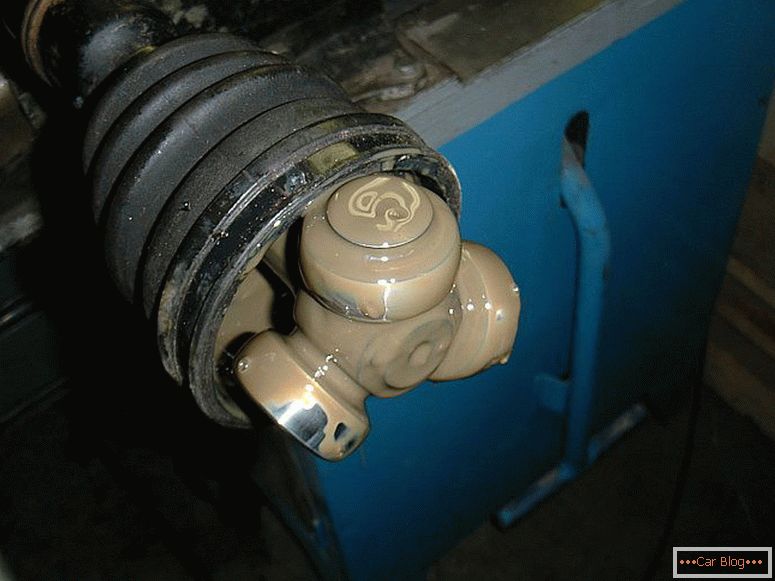

To press the grease into the CV joints, you will need to separate them into internal and external parts. First, we will deal with the lubrication of the inner CV joint, which is also called the tripod due to the use of the original design with three supports. Having pulled for a lock ring, we separate the driving mechanism from the case of an internal SHRUS. Be careful to avoid damage to the unit during installation after lubrication, you will need to put on the body and supports a small notch, which during the assembly will have to be combined with each other. Before you apply a new lubricant, you will need to remove the old material along with the accumulated dirt in it - for this it is rational to use a pair of thick rags and paper wipes that are used when washing the car.

Now it is worth doing the outer CV joint - in order to extract the balls from it, it will be necessary to push the separator tightly on one side, and if it does not give in, then make several blows with a hammer through the wood. Pulling the asterisk and the separator, in a similar way, mark their position on the body, and also remember the sequence in which the balls were installed. The outer CV joint will also need to be cleaned of old grease and, if necessary, thoroughly washed with a special agent. Do not use ordinary soap and car shampoos - left on the walls of the case, they can react with the lubricant and violate its properties.

When all parts are cleaned of old grease and washed, gently wipe them again with a dry paper towel and begin the assembly procedure. First, it is necessary to fill both bodies of the CV joints with lubricant by about one third and install the internal components. Check that they remain mobile and start filling. Be careful - the outer CV joint should be filled with lubricant so that it slightly protrudes beyond its limits, and in the inner one it should be slightly underfilled so that 3-5 mm is left to the edge. After that, continue assembling the components of the drive system in the reverse order, not forgetting to combine the marks on the internal components of the CV joints and their housings. Before installing the anthers, put a little grease in them and gently distribute it so that it evenly covers the inner surface.

The frequency of replacement of any lubricant in normal conditions is 80-100 thousand kilometers, which allows to achieve the perfect preservation of the CV joints of the car. However, experts recommend reducing this mileage to 60 thousand kilometers, if the car is operated in harsh conditions, the driver prefers active driving style or participates in sports competitions. A similar rule is used for SUVs, which are often used for its intended purpose, and their owners are recommended to check the status of anthers more often, since their rupture can cause serious damage. If a car passes a sufficiently small distance within a year, it is recommended to replace the lubricant in the CV joints in 4–5 years, since by that time it will completely lose its properties. It is also necessary to change the lubricant if the machine costs more than 8–9 months without moving or is used occasionally for one and a half years - similarly, it is possible to avoid aging of the lubricant in the CV joints, which can lead to accelerated wear of the assembly.

How to choose a lubricant?

To date, the best option for lubricating CV joints are compounds containing molybdenum disulfide - they provide reliable protection against corrosion, and are also able to significantly reduce friction in the transmission of the car. It is also worth knowing that lubricants containing sodium and calcium, zinc, graphite, iron-containing, hydrocarbon compounds can not be used to protect the CV joints - they cause them significant harm and contribute to accelerated wear. In any case, before purchasing a specific lubricant, you will need to read the car's instruction manual to find the manufacturer's recommendations in it. If we talk about brands of lubricant manufacturers, it is better to give preference to such companies as BP, Texaco, ESSO, Liqui Moly, Mobil. However, domestic lubricants SHRUS-4, Litol, Fiol, ShRB-4 and their analogs are practically not inferior to the products of the above-mentioned manufacturers in their basic properties.