>

Speaking about the main components of the car, we often remember the engine, transmission and body, completely forgetting about the suspension, or, as it is often called, the chassis. However, the value of the suspension is difficult to overestimate, because we feel its work in overcoming any irregularities - it is responsible for the comfort of the passengers, as well as their health, because the strong impacts and vibrations do not affect the human body in the best way. Also, the undercarriage is able to protect other components of the vehicle from damage, since not only people but also equipment can suffer from the mentioned troubles. Suspension directly affects the car’s handling, as the vehicle’s course stability depends on absorbing the impact energy and canceling out oscillations. There are many types of chassis design - so before you buy a vehicle you need to know what the best vehicle suspension will be for you.

Theory

In the history of the global automotive industry, various variants of suspension construction have been tried - from classic ones that have switched to motorized equipment from old carriages to very exotic ones. As evolution leaves on the planet only viable species, so the inexorable progress has brought to our days the most successful types of car undercarriage. All modern types of suspension consist of two main elements. The elastic element absorbs impact energy, providing comfort and protecting the rest of the car’s components from destruction. The shock absorbers dampen the vibrations that inevitably arise when driving through irregularities - without them, the car would jump for a long time, delivering terrible discomfort to the driver and passengers. To connect the body and wheels use special support elements, which are called suspension arms - their design also has a considerable impact on consumer properties of cars.

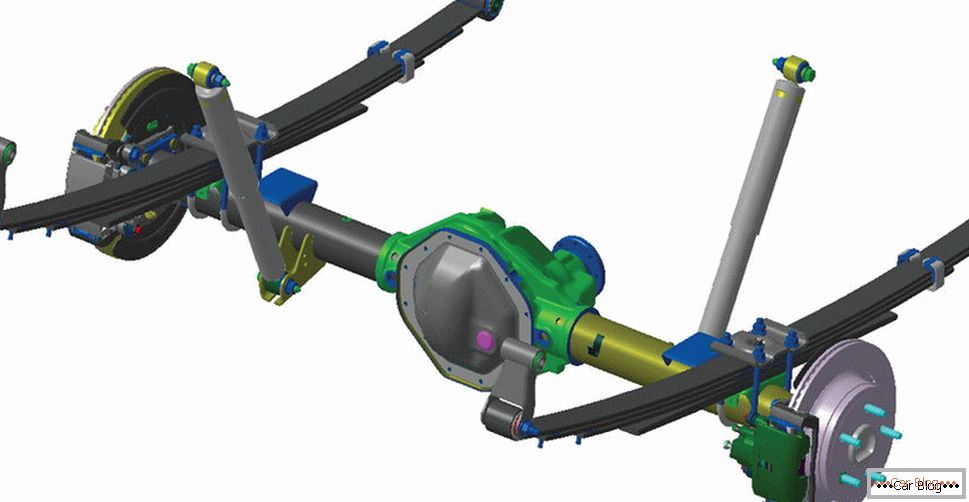

Читать далее о том, какая подвеска автомобиля лучше-->Принцип действия подвески на различных автомобилях может существенно отличаться. Первые машины, появившиеся на заре автомобилестроения, имели исключительно зависимую подвеску, которая доставляла массу неудобств людям. При колебании одного колеса второе совершает движение в противоположную сторону по принципу маятника — это приводит к тому, что наезд на крупную неровность встряхивает автомобиль и сбивает его с выбранного курса, заставляя водителя крепко держать руль, возвращая транспорт в исходное положение. Сейчас зависимая подвеска часто устанавливается на заднюю ось легковых автомобилей и небольшой коммерческой техники. В некоторых грузовиках такая ходовая часть может находиться и на передней оси, но подобное техническое решение встречается все реже.

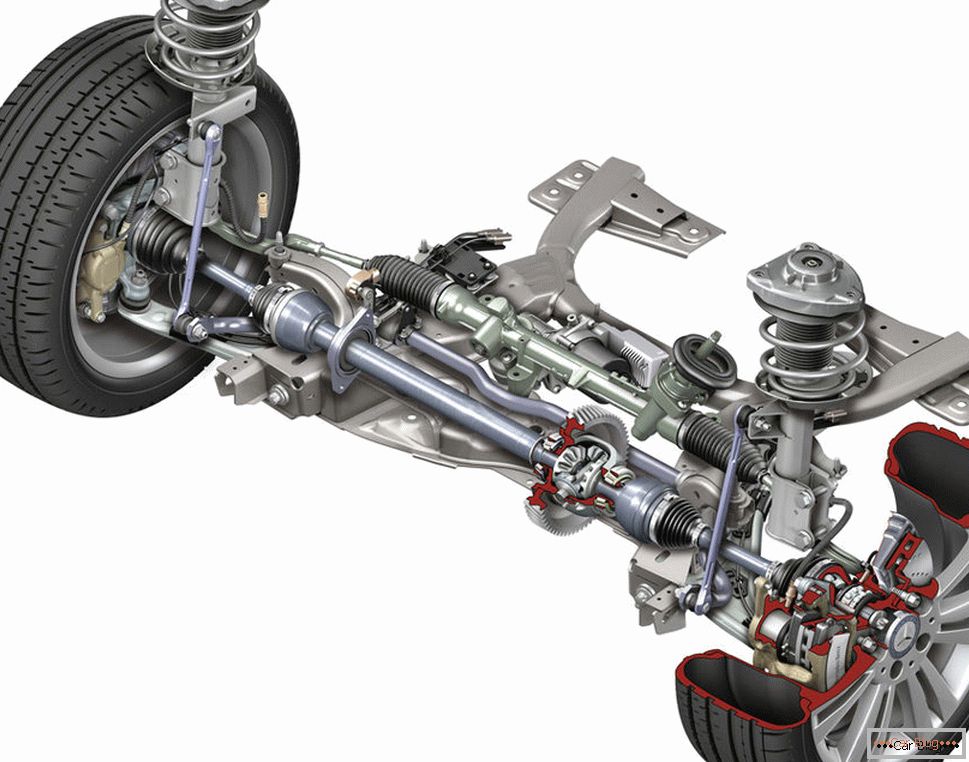

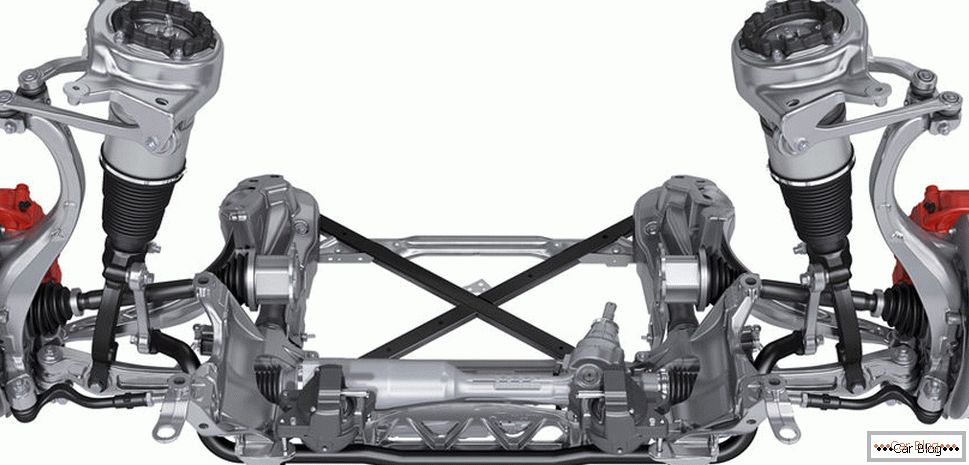

More modern can be called independent suspension. There is no mechanical connection between the wheels mounted on the same axis, and they can oscillate independently. As a result, such a suspension allows you to pass even large irregularities, without shaking up the whole body. Initially, such a design appeared on passenger cars, especially in dire need of a tool that would ensure the efficient absorption of shock energy. Behind them, an independent suspension began to use sports cars, and today we can see it on the front axle of any car.

Supporting structures

More at the dawn of the automotive industry was created double-lever suspension, which has a very simple design. Its main feature is the connection to the wheel hub at the top and bottom points, which allows for large strokes, but does not make it possible to completely dampen vibrations and vibrations. As a result, the double-lever suspension is ideal for driving on bad roads, where the ability of the chassis to provide comfort is important, but precise handling is not so significant. Today, the double-lever design is often used in the creation of off-road vehicles and vehicles of the budget price category.

The middle of the XX century gave the world the suspension MacPherson, which was named after its inventor, one of the designers of Ford. Earl MacPherson proposed to make the suspension more compact by hiding the shock absorber inside the spring and significantly simplifying the chassis design. Thanks to his invention, compact and subcompact models, as well as many sports cars, were able to see the light. Racks MacPherson, which in the domestic technical literature were called swinging candles, made it possible to improve controllability without loss of comfort, but they had very limited moves. Cars with MacPherson strut are ideal for driving on a flat road with high-quality coverage, but can not go on a serious off-road without the risk of damage to the body and essential components.

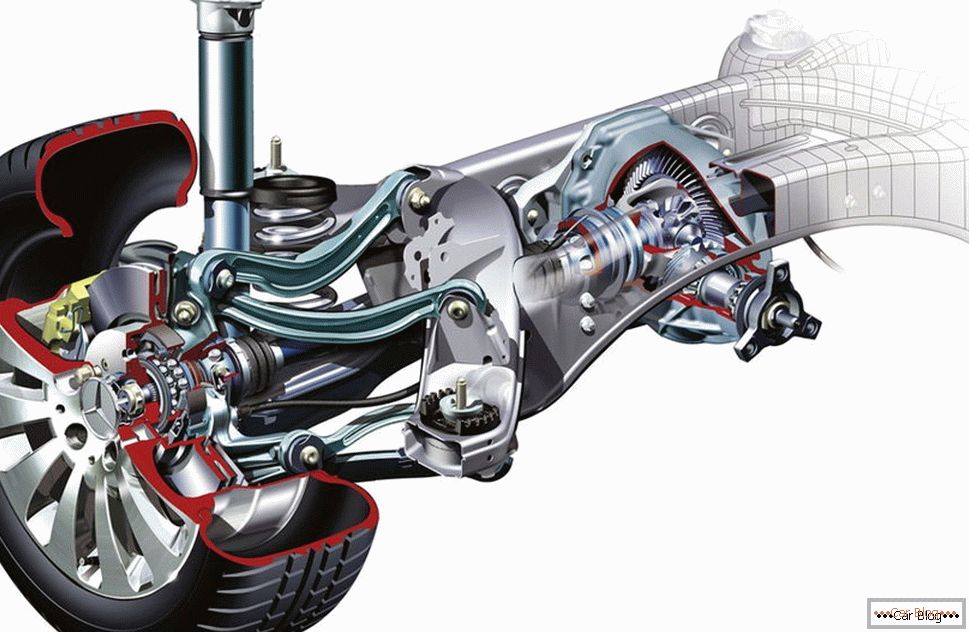

In two sides of the world, at the same time, work was underway to create an improved version of the suspension - as a result, in the 70s, the Germans and the Japanese presented a multi-link design that could boast of three supports. Today, options are being developed that have up to five levers, which allows us to achieve our advantages. Among the positive features of the multi-link suspension include:

- Precise handling;

- The absence of vibrations in the presence of cracks on the road and the absence of steering oscillations during the passage of irregularities;

- Greater reliability and durability.

However, this undercarriage design also has its drawbacks - in particular, its vertical movement is even more limited than that of the “swinging candle”. In addition, such a suspension is almost impossible to make silent and soft - so it is often installed on sports cars, which are intended solely for driving on good roads, devoid of large irregularities.

There are more exotic designs, but in aggregate they are installed on less than 5% of cars. It cannot be said that all the types of suspension listed above are ideal or at least have indisputable competitive advantages over alternatives. However, the chassis built on this principle is a good compromise between handling, comfort, reliability and maintainability.

Elimination of vibrations

The function of shock absorbers is not fully understood by all motorists, so it’s worth repeating the theory. These car suspension components absorb the energy of the blows, but not the one that is reported to the chassis when driving through bumps, but the one that returns the body, forcing the car to sway. In fact, shock absorbers stop vehicle vibrations  Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru, making possible a comfortable and safe ride. Dampers can vary in level of stiffness - the bigger it is, the faster the body will stabilize. However, excessive rigidity, although it significantly improves handling, significantly reduces the comfort of the vehicle.

adom.ru, making possible a comfortable and safe ride. Dampers can vary in level of stiffness - the bigger it is, the faster the body will stabilize. However, excessive rigidity, although it significantly improves handling, significantly reduces the comfort of the vehicle.

Most of the cars on the assembly line of the manufacturer is equipped with classic hydraulic shock absorbers, in which the working element is mineral oil. By changing the composition of the fluid and its volume, such properties can be given any properties — due to this, they are very widespread. If the driver likes active driving, but is not ready to sacrifice comfort completely, he can be advised to choose gas-oil shock absorbers, which are also called gas-supported suspension. Their stiffness is somewhat higher, and it can progressively change depending on the position of the rod.

The best option for fans of motor racing can be called gas shock absorbers, which stop the body vibrations in a matter of seconds, allowing you to maintain the perfect controllability of the vehicle. However, the driver and passengers will have to put up with considerable stiffness, so these suspension components are rarely installed on ordinary middle-class cars. For off-road vehicles, special requirements for the suspension design, special-purpose shock absorbers with portable tanks are produced. Their energy consumption is several times higher than that of the standard models described above, which allows you to avoid damage to the machine even with detachment from the ground and subsequent fall. An example of such parts can be called Fox Racing Shoxx shock absorbers widely known to fans of off-road tuning.

Load absorption

Despite the fact that engineers are now paying close attention to the shock absorbers or the supporting structure of the suspension, most of the work in the chassis always performs an elastic element. It depends on him how comfortable the ride will be on poor coverage, and how much the fluctuations will affect the handling of the vehicle. For many years, automotive designers have developed several popular types of elastic suspension elements - they should be considered in more detail.

The immortal classic

Horse-drawn carriages of the pre-automobile era were equipped with their own suspension, which in most cases was a spring design. Interestingly, until the end of the 19th century, the springs were an unaffordable luxury for most people and everyone, except the richest aristocracy, had to be content with tough carts. When switching to cars, the spring suspension once again became a practically non-alternative scheme, but as early as the 30s of the 20th century a variety of different variants of the undercarriage appeared. Today the last passenger cars equipped with a spring running gear are leaving the roads - this type of suspension is stored exclusively on commercial vehicles with a large carrying capacity.

Already it can tell a lot about the main advantage of the springs - they are very reliable and durable, and also able to absorb very large loads, protecting the car from damage, and the human body - from receiving significant damage. The spring suspension is considered to be the most benign for shock absorbers, since it is able to compensate for body vibrations by rubbing individual sheets together. However, the minuses of the springs are much more - so, its most important disadvantage is considered to be the mediocre energy intensity, which does not allow to make the car comfortable enough. Also, the handling of a car with such a chassis always leaves much to be desired. That is why the scope of the spring suspension today remains commercial vehicles and some passenger pickups.

Popular option

The most common at the present stage of development of the automotive industry has received a spring layout of the chassis. Such an elastic element absorbs loads fairly well, providing excellent controllability of the vehicle. In this case, the manufacturer can independently determine the number of turns of the spring and its thickness, changing the stiffness of the suspension. There are special springs with progressive characteristics in which the thickness of the coil is reduced to the edges - this allows you to get balanced parameters and achieve good reliability. The plus of the springs is the ease of repairing such a suspension and the low cost of spare parts.

However, the minuses of the springs are no less than the important advantages. The main thing is the limited load capacity of the suspension - with long-term exposure to high gravity the springs change their shape, which is due to the peculiarities of the molecular structure of the metal. Accordingly, such a chassis will no longer be able to absorb the previous amount of energy and ensure good handling. The springs also wear out quickly and can even burst under the impact of shocks. After a long drive on the road in a car with a spring suspension driver will wait for an unpleasant surprise.

Successful alternative

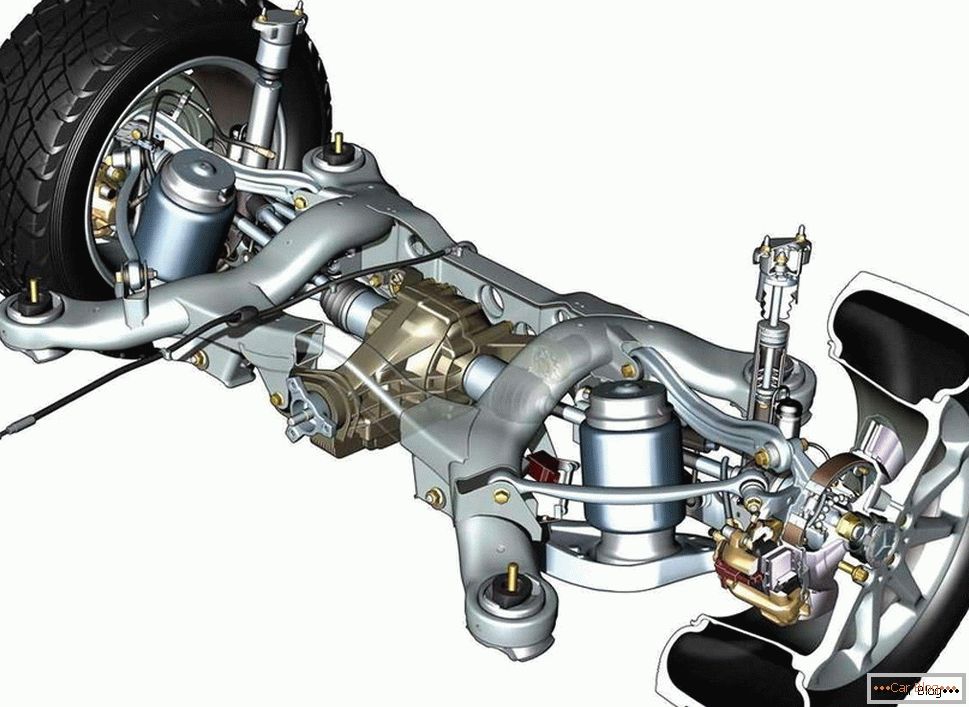

Eliminate most of the problems inherent in the spring suspension, it was possible to military engineers who tried to create a reliable and durable chassis for heavy armored vehicles. The twisting rods developed by them resembled “springs in reverse” - they were called torsions. Such a design quickly ceased to be the prerogative of tanks and armored personnel carriers, spreading to trucks and cars of a compact class. The most important advantages of the torsion suspension are:

- Small dimensions;

- Durability, reliability, endurance, maintainability;

- Insensitivity to shock loads;

- Low cost;

- Derivative components.

However, the universal option, suitable for any car, torsion bars did not become. The reason is simple - the torsion undercarriage is inferior to the spring one in terms of comfort and control accuracy of the machine. Also, torsions are somewhat more difficult in periodic maintenance and overhaul, which imposes its own restrictions on their use. More often they are used in commercial vehicles and off-road vehicles, where very high reliability is important, but the springs are not suitable due to poor handling and a low level of safety. If we talk about compact cars, their designers are willing to consciously sacrifice comfort and control for the sake of further reducing the size of transport.

Premium class

Even in the prewar period, experiments were conducted with the installation of pneumatic cylinders on cars - they could replace the traditional types of chassis. However, pneumatics was widely adopted only in the mid-80s, when its characteristics were made acceptable. The main advantage of air bellows is their exceptional softness - the people inside the car almost do not feel the shocks and vibrations that occur when driving irregularities. At the same time, there is no significant deterioration in controllability compared to the traditional types of running gear described above. Changing the pressure in the pneumatic cylinders, the driver can adjust the stiffness of the suspension, the height of the ground clearance, as well as other important parameters - before this had to be done using a special hand pump, and today the electronics are responsible for pumping.

Of course, this version of the undercarriage also cannot be called ideal, since it is quite expensive to produce when it comes to a modern suspension system with automated control. A large number of components makes the design vulnerable to damage and difficult to recover after a long drive on roads with poor quality coating. The cost of repair after a serious breakdown can be comparable to the price of a small car. That is why the air suspension is often installed on expensive cars with increased requirements for comfort. Since it combines comfort, precision of control and high payload, pneumatic undercarriage can often be seen on modern main tractors and other heavy commercial vehicles.

Innovation

Often we hear about the adaptive chassis, which significantly improves the controllability of the vehicle. Experiments on the creation of such a high-tech suspension were conducted back in the 50s of the XX century. Then most of the engineers relied in their work on components with progressive characteristics, which made it possible to change the stiffness of the undercarriage depending on the position of its individual parts. However, now some companies are experimenting with electronics that control the opening of valves in shock absorbers, limiting the position of the elastic part and many others. The result of the use of such a suspension really becomes a significant improvement in handling, and the car does not lose comfort.

A big rarity are fully-driven cars - if not to talk about military and specialized vehicles, then Nissan has achieved the greatest success in their creation. In her legendary Skyline model, there were steering rods that could change the position of the wheels by 5 degrees - this increased the maneuverability of the vehicle. In modern Infiniti models, special electric actuators are responsible for moving the wheels - with their help, the wheels turn in the opposite direction compared to the front ones at low speed and in the same direction after overcoming the threshold of 60 km / h. In cars, Lexus suspension is equipped with elastic elements that allow the wheels to deviate at a small angle - this solution seems justified in terms of efficiency and simplicity, but not too reliable.

Perfect balance

Choosing a car for its suspension, do not forget about the conditions in which it is supposed to operate it. So, for off-road will be the optimal scheme with two levers, as well as torsions or pneumatic cylinders. Moreover, SUVs are almost never equipped with a rear independent suspension, since it does not allow to maintain a constant ground clearance and ensure the safety of important vehicle components. Powerful sports cars and luxury cars are often equipped with multi-link spring suspension. But the cars belonging to the budget and middle class, usually satisfied with the "swinging candle" MacPherson, which combines many advantages.