>

In any manual for the car you can find mention of the need to tighten the threaded connections with a certain torque. Experienced masters can achieve the required strength "by eye", using only their experience, but even they can be wrong.

The consequences of mistakes can be very unpleasant - from the failure of the wheel studs to the irreparable destruction of the engine block. That is why experts strongly recommend purchasing torque wrenches for every motorist who is self-repairing his vehicle.

Читать далее, какой динамометический ключ лучше-->При этом нужно знать, какой динамометрический ключ для автомобиля лучше купить для использования в конкретных обстоятельствах.

Main varieties

The simplest and most common version of such a tool is the arrow keys, which are also called torsion keys according to the type of mechanism used in them. They show the value of torque when exposed to it, for example, when you press it with your hands. Such torque wrenches have no safety mechanism when the permitted torque is exceeded. In addition, there is no need to talk about great accuracy - the error can reach 15%.

If you often perform complex work with the need for precise torque limiting, it is better to buy limit torque wrenches. After reaching a predetermined torque, they simply cease to transmit it to the threaded connection being processed. Previously, breaking torque wrenches were popular, which went out of engagement immediately after reaching the maximum value.

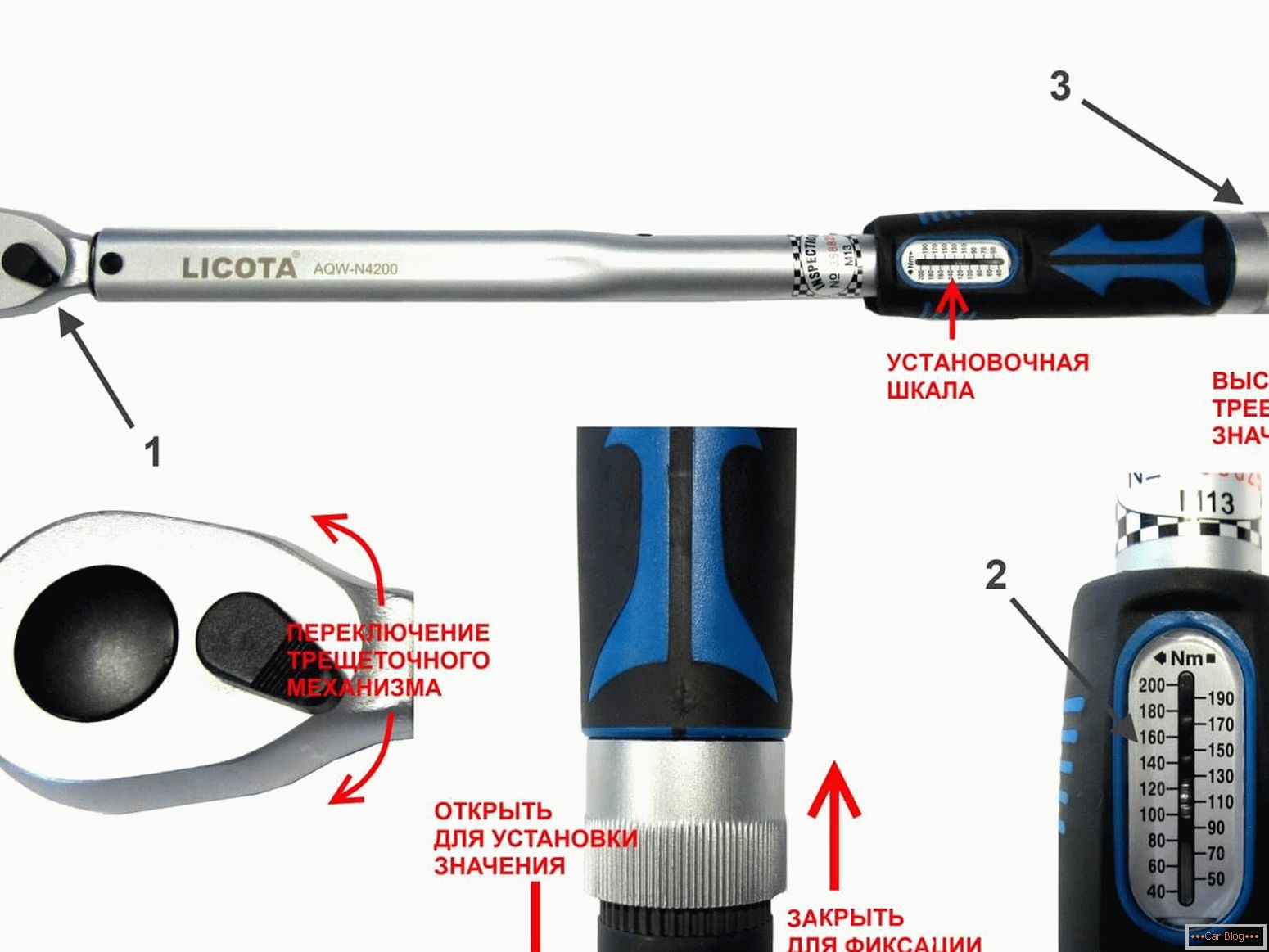

However, their reliability really left much to be desired, therefore, these mechanisms were replaced by ratchet keys. Such torque tools use a ratchet mechanism known to every person, forcing it to scroll aimlessly over the wrench head when the permitted torque is exceeded.

The third option is electronic devices, which are very widespread at professional service stations. If the torque wrench with a ratchet mechanism reaches an accuracy of about 5%, then in this case it can be kept within 1%.

The design of the tool may include a protective ratchet, but more often there are keys with a liquid crystal indicator, whose task is only to inform the user. A significant disadvantage of electronic torque wrenches is their high price, which makes such tools almost inaccessible to private owners.

Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru

adom.ru

There are also special heads that are worn on wrenches or rolls of various sizes - most often they use a ratchet mechanism that stops the transmission of torque over a set limit.

However, in professional wrenches, the torque is regulated directly on the device itself, so the torque heads are installed only on the simplest home appliances and hand-held devices. On sale you can find large power wrenches with long handles, which are ideal for performing the most complex work.

Specific Models

According to GOST, torque wrenches must withstand a force of up to 60 Nm, after which their slippage, the destruction of the metal of the jaw or even the fracture of the handle is allowed. However, some operations require much more effort, so there are also models on the market that can withstand really enormous efforts. You also need to pay attention to the hardness of the metal from which the torque tool is made. The minimum value is 30HRC, although experts recommend picking up keys for which this indicator reaches 50–55 HRC and more.

Force Torque Wrench

Independent tests show that the best torque wrench is manufactured by Force. Its limit type regulator allows you to set an incredible torque value - up to 350 Nm, and even in this position, the error of the measuring tool does not exceed 3%.

An additional advantage of this model is the presence of a ratchet mechanism with the possibility of independent selection of the direction of rotation. The test made it possible to obtain confidence that the stated load corresponds to the real one - even with a five-minute application of such a large force, the key does not break and the structure of the metal does not break. The key can be recommended to employees of professional autoservice enterprises, as well as truck owners.

Torque wrench KABO

The second well-deserved place is occupied by the key known to many masters of service stations of the KABO brand. This torque tool has a very convenient adjustment - it has two rings of adjustment, one of which allows you to set the value with an accuracy of 10 Nm, and the other - just 1 Nm. The key has phenomenal accuracy - even with a maximum torque level of 210 Nm, the error does not exceed 2%.

For convenience, it also provides a flag switch that allows you to choose the direction of rotation. In comparison with the model discussed above, this torque wrench has two drawbacks, represented by limited torque and moderate hardness (45 HRC), which determines the average service life of the device.

If you need a compact torque wrench, you need to pay attention to the model OVERHAUL OH3138, which is also made in the form factor ratchet. The limiting value of the torque for this device is 100 Nm, however, tests have shown that even one and a half times the specified value does not lead to a broken arm.

Instant fracture occurs only with a sharp application of force of more than 300 Nm, which is almost impossible to achieve with an independent car repair. The advantage of this model is the comfortable rubberized handle, which allows you to do without injury when tightening the most durable threaded connections.

If you are thinking about which torque wrench to choose, without spending a lot of money, pay attention to Russian products - STO experts speak well about the tools of the brand "Master" The key with an extended knob is designed for 210 Nm, and it could withstand a heavy load.

Torque Wrench

However, the tool brings a very weak handle with a hardness equal to just 32HRC - with great effort it can simply break off, leaving you without an expensive key. Pleases the tool and the error that does not exceed 3% when the indicator reaches 30 Nm. However, with less tightening efforts, the difference between the actual performance and that required for repair can reach 10%, which makes the device available only for home use.

Accuracy and Reliability

When choosing a torque wrench for self-repair of the car, you need to give preference to a device with perfectly balanced characteristics. It is not at all necessary to purchase tools with limit values of torque, reaching 250–300 Nm, since 200 Nm will be enough for most of the work.

Also, you do not need devices made of heavy-duty steels with a hardness of 50 HRC - enough 35-40 HRC. Following these simple guidelines will help you get a quality tool at no extra cost. However, if you are going to engage in professional repair of cars or purchase keys for a truck, you should choose only the best models from the best.