Modern cars to reduce speed apply mechanisms that use in their design the force of friction, and materials with high frictional properties. At the same time, even high-quality brake pads are subject to wear during operation and need to be replaced over time. We will understand when to change the brake pads, and determine the interval by time or by mileage.

Content

- 1 Operational factors

- 2 Design features

- 3 Signs of wear

Operational factors

Some drivers carry out the replacement after 50 ... 60 thousand km, and for others the deadline is already 10 ... 15 thousand km. The main factors in this situation are the method of operation, driving style, the manufacturer of the pads and the type of brake system.

Также стоит обратить внимание на сопутствующие элементы системы, от состояния которых зависит, after how much to change the brake pads:

- adjusting thrust with fasteners;

- various seals and protective anthers;

- cuffs and hydraulic hoses;

- damping springs or locking brackets.

The wear of these components also leads to the rapid abrasion of the friction linings.

The quality and design of brake discs or drums has a direct impact on the operation of the brakes as a whole. Ventilated discs from well-known manufacturers will last much longer due to optimal conditions, the mileage of the pads with them will increase.

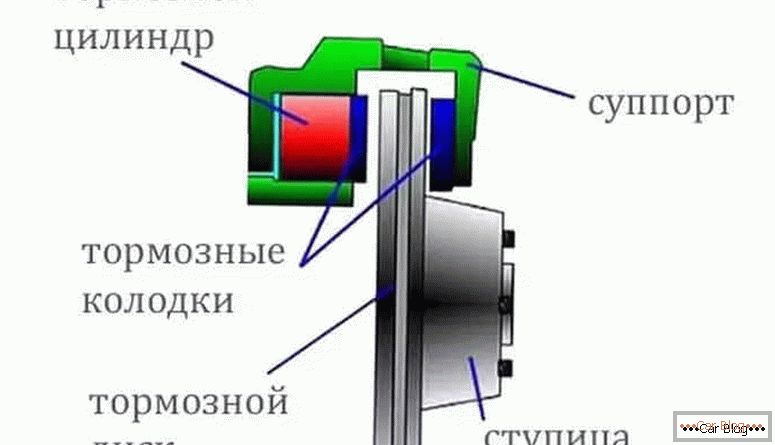

Carrying out the diagnosis of the brake system, it is worth checking the correct installation of the caliper. Its misalignment affects the evenness of wear. The property affects the effectiveness of braking. To notice this phenomenon can be unevenly wiped lining.

The negative phenomena include the following phenomena:

- temperature conditions;

- presence of aggressive reagents and salts.

These circumstances are capable of reducing the operating time for products, since the main friction elements lose the physico-chemical parameters laid down by the manufacturer.

It is recommended to replace the pads for all wheels simultaneously.. This will ensure the quality of the system.

Construction features

Most experts recommend to inspect, and sometimes already replace the pads on the disc brakes of domestic cars with a run of 10 ... 15 thousand km. Rarely low cost cars exceed this interval of 20 thousand km. For foreign constructions, the admissible term will be 15 ... 20 thousand km of run. Correction is made depending on driving style.

See also: Device and principle of operation of the vacuum brake booster and how to check it

For a drum-type brake design, a motorist may not worry sometimes and up to 100 ... 150 thousand kilometers. Therefore, the answer to the question of how often to change the brake pads depends, in addition to operational factors, on the system design.

It is important to have an idea about the material from which the friction linings on the pads are made. Automakers sometimes include more than a dozen components in the composition in order to ultimately achieve the necessary properties of the material. As a result, it allows to achieve a soft and silent operation, but at the same time they remain tenacious even with aggressive driving style.

The structure of the lining is of several types:

- Polymetallic. The material has durable properties and has high heat dissipation. It includes 25 ... 60% of metal compounds from steel powder, copper impregnations or metal cobwebs. The disadvantages include increased noise during operation, as well as a possible decrease in efficiency during frosts.

- Asbestos-free. After the ban on the use of asbestos, manufacturers began to use organic materials that include glass, rubber and kevlar components. Braking with them is quite soft and quiet. However, with intensive use, the pad wears out quickly, wiping the pads into dust.

- Low metale. The composition of the material is a compromise between the previous types, and on the shelves they can be found most often. Domestic automakers use this type of pad in the basic configuration of modern cars. Up to one third of the copper material is used in the structure or a steel mesh is used. An increase in the mass fraction of metallic inclusions can cause more noise when braking.

- Ceramic. The material belongs to the most advanced technologies with improved quality. Although the price tag on them is higher than similar ones, but this is offset by increased lightness, less noise and a lower degree of wear. The basis is ceramic fibers and a small amount of non-ferrous metals. At the expense of a strong basis do not create dust. Products pay for themselves quickly due to long service life.

Replacing the pads from the base in your car with better ones, such as ceramic ones, you can forget about the problem with the brakes by several tens of thousands of kilometers.

Signs of wear

The driver can find out about the degree of wear of the pads by indirect signs. It is only necessary to correctly interpret these signals. One of the main symptoms is an increase in stopping distance, as well as a violation of straightness during braking. The negative factors include an elongated pedal stroke and a noticeable decrease in its rigidity.

The car owner should check the status of the pads during intermittent locking during braking. This occurs after the abrasion of rubber, resins and other inclusions, after which there is a frictional interaction of the metal elements of the pad with the brake disc.

Wear forms the visibility of the wheel beating when braking. Squeaks, gnash and other extraneous noises appear. This behavior can lead to jamming of the pads and complete blocking of the wheel, which will have a destructive effect on the entire unit.

Modern cars are equipped with specialized sensors pad. After the pad is reduced to a critical size, the driver receives a notification. In the mechanical devices will be creaking. For electronic monitoring units, a light signal is provided on the instrument panel. The light comes on every time the ignition is turned on.

Also, some manufacturers put special control grooves, and when the pad is erased to such an extent that the grooves disappear, then it must be changed. It is undesirable to bring the pads to a state in which the pad decreases below 2 ... 3 mm.