For the full operation of a gasoline internal combustion engine, at least two conditions are necessary. This is a timely supply of fuel and spark, which will ignite the combustible mixture.

The fuel system is responsible for supplying fuel to the combustion chamber, and for the appearance of a spark - the ignition system, where unconditionally the candles are the main performer of gasoline ignition. It follows that these two systems must always be in good condition.

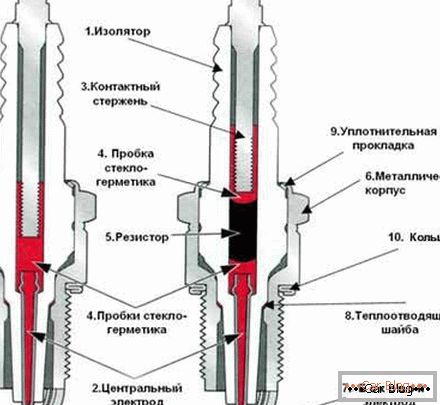

To better understand the problem of failure of the spark plugs, we will conduct a small review of their design.

Fresh ignition, is a metal case with a turnkey hexagon (there are different sizes), and the threaded part, at the end of which there is a "negative" electrode. Inside the case itself, a “positive” electrode (often copper) passes, which is separated from the steel case by a ceramic insulator. In the upper part of the steel electrode there is a thread on which a figure nut is screwed on for reliable connection with the high-voltage wire. In the lower part of the electrode protrudes from the body of the insulator. Between the "plus" and "negative" insulator there is a necessary gap set by the manufacturer, in which a spark appears.

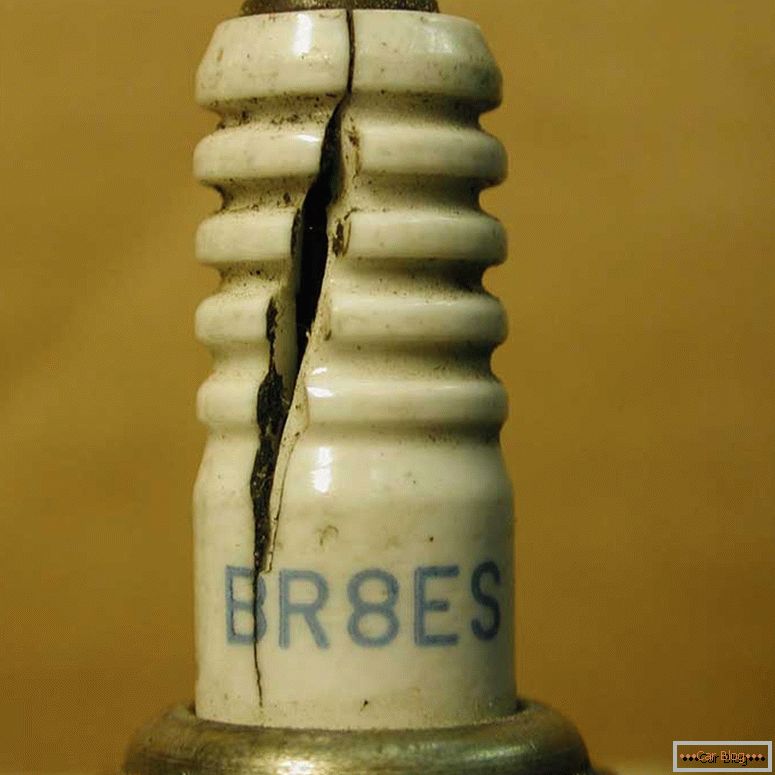

Proper performance of the candle will take place until a candle is formed on the candle, there will be no traces of oil. Also, if the integrity of the insulator is not broken or the gap is unchanged. For example, if an insulator bursts or breaks, the voltage will partially or completely go to ground, in which case the candle starts to work intermittently or fails altogether. The result is that the engine begins to troit and loses its power.

The same phenomena will occur if there is no gap between the electrodes. Engine oil is also a good conductor, as a result, if there are oil leaks on the candle, the spark will go the shortest way to ground.

Spark Plug Specifications

The main parameters are: the diameter and length of the threaded part and the heat rating.

A Kilare Number refers to the amount of pressure when Kiln ignition occurs in the combustion chambers. All manufacturers must indicate in the annotations the heat value for this type of engine and the type of candles. If you install candles with a “non-native” heat rating, this will negatively affect their self-cleaning and thermal operation of the engine.

See also: Car immobilizers, their varietiesThe number of candles candles divided into three types:

- Cold (20 and above);

- Medium (17–19);

- Hot (11-14).

The higher the number indicated, the higher the temperature that the spark plug can withstand during operation. Candles with low numbers often fail quickly, because do not withstand high temperatures.

The frequency of replacement candles

Spark plugs are consumables, as the car runs, they must be replaced. Different manufacturers give different recommendations for replacing candles. It is characterized with the design features of the engine and the execution of the candles themselves. The type of ignition system also affects the life of the spark.

Ignition system and types of candles

Ignition system:

- Contact;

- Contactless;

- Electronic.

Types of candles:

- Classic;

- Prechamber;

- Iridium;

- Platinova;

- Flare;

- Multi-electrode.

Replacing the classic ignition sections is provided every 30 - 60 thousand kilometers, while platinum and iridium will serve more than 100 thousand kilometers.

Main symptoms of faults

- At night, a spark may be seen between the candles and the tip;

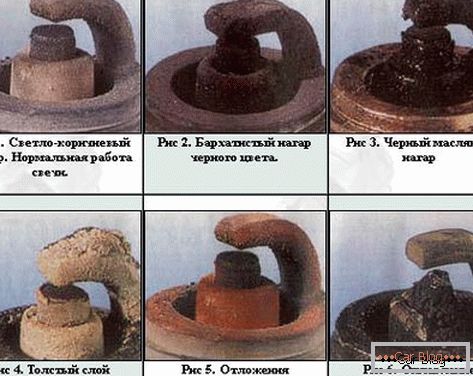

- Wet or sooty electrodes;

- Glaze on the electrodes;

- Crack on the insulator;

- Melting electrodes.

Indirect signs of malfunction candles include: misfire, engine "troit", increased fuel consumption, unstable start, the smell of not exhaust gasoline from the exhaust pipe.

There are several options for testing the continued suitability of a candle:

- A device that simulates the pressure in the cylinder at the end of the compression stroke;

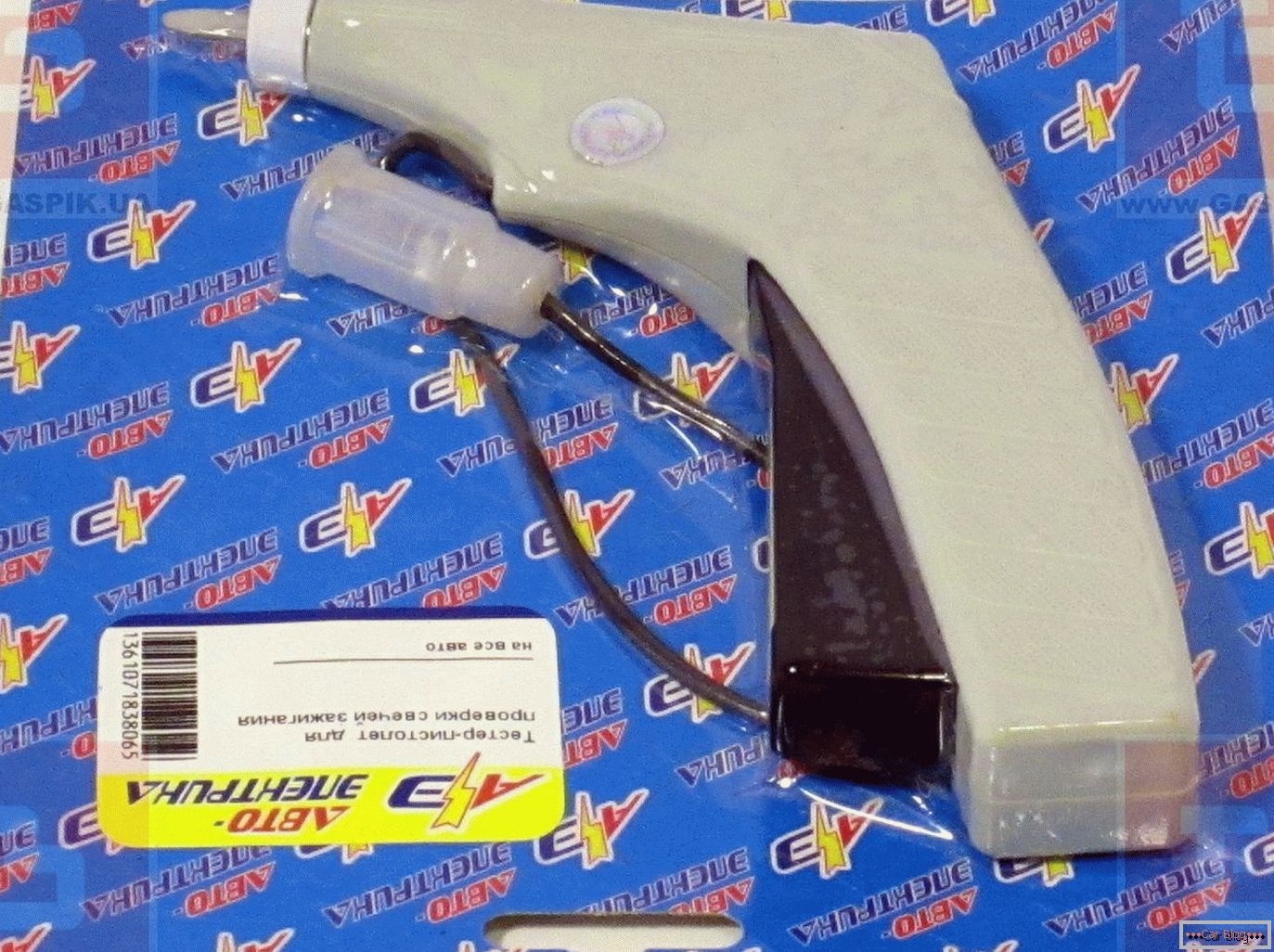

- Pistol - probe;

- Ignition spark check;

- Applying a spark to a candle by applying it to the mass and applying voltage through the ignition.

Instrument check

The device for checking the spark is a manual device for creating pressure and a coil for feeding a spark. The device has a camera with a viewing window into which the candle is screwed. Pressure is pumped into the chamber by manual pumping up to 10 atm, a high-voltage wire is put on the spark plug and the spark supply button is pressed. Then through the viewing window visually determined the performance of the candle. If between the electrodes the spark of a blue color stably holds, such a candle is considered to be in good condition. If the spark is red, or runs in a circle, is constantly interrupted, this candle must be cleaned, check the gap and check the entire cycle again. If it did not help, such a candle is clearly not working. Typically, such devices come with a sandblasting chamber.

Pistol sampler

A candle is inserted into the pistol hole, the trigger is pulled and the inspector observes the spark. A lawsuit will either appear or not. Thus, this method has a big minus. A spark is created at atmospheric pressure and during operation in the combustion chamber it may not fail as it creates compression pressure and other conditions for the formation of a spark, and the pistol cannot provide this probe.

Spark test

The candle is twisted out of the cylinder and tightly pressed against the metal part of the car. By scrolling the starter voltage is applied to the candle, and the presence of a spark is checked.

For cylinder interruptions

Alternately, on a running engine, a high-voltage wire is removed from each cylinder, if during the removal of the next wire you did not notice any deviations in the engine, then this spark plug is faulty. It must be said that this method is quite dangerous, because high-voltage wires are often "punch". You can get an unpleasant discharge current.

Causes of Spark Plug Failure

The spark plug works in harsh conditions, high pressure and temperature, simply requires the candle to be made of quality materials

Significantly reduces the life of the candle, it is the presence of oil in the combustion chamber, it is gradually deposited as a deposit on the electrodes, this complicates the appearance of a spark, or completely prevents it.

Failure of high-voltage wires or malfunction of the ignition coil also entails the "loss" of the spark. Here it is necessary to find the cause in these two ignition elements and replace them.

Failure in the timing drive (gas distribution mechanism) is also the reason for the absence of a spark. This is due to the fact that the moment of fuel supply and the moment of sparking are out of sync.