By purchasing a four-wheeled pet, every motorist wants to preserve its original appearance. Owners show their passion for cars in different ways. Some seek to provide quality service, others boast of battle dents. Many still intend to keep their car in the most original form.

But the car, like any technique, is subject to mechanical damage over time. This can happen in different situations:

- in the process of washing;

- when using different shampoos with abrasive particles;

- during a negative environmental impact.

Content

- 1 Liquid glass for cars, what is it?

- 2 Properties trendy material

- 3 Polishing a car with liquid glass do it yourself

- 4 Processing auto liquid glass, the pros and cons

- 5 Stepwise processing algorithm

- 6 Processing popular brands of liquid glass

Liquid glass for cars, what is it?

All equipment has its estimated uninterrupted operation time and expiration date set by the manufacturer. As a rule, more attention is paid to car body care. Recently, the attention of car owners attracted the car's cover with liquid glass.

Liquid glass for a car is a nanospray which can be sprayed on any surface. It protects against dirt, bacteria, high temperatures, ultraviolet radiation and even acids, repels water.

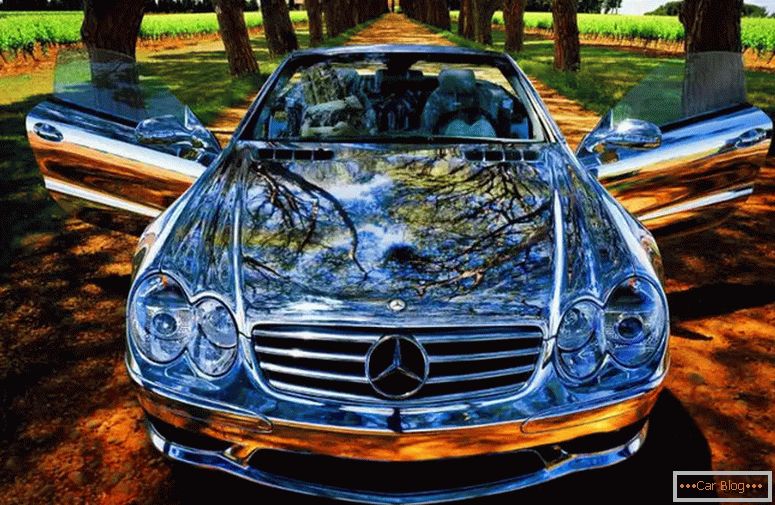

The coating with liquid glass gives the car a pleasant shine and keeps it, according to foreign experts, for three years. However, on our roads, this period rarely lasts more than a year. It is noteworthy that no other similar protective compound known to date can give such a guarantee. Polish, based on liquid glass, perfectly protects the vehicle body from mechanical defects from scratches.

Properties trendy material

Liquid glass is endowed with positive characteristics. We list them:

- invisible to prying eyes;

- non-toxic to people in the cabin;

- Absolutely safe for the environment.

The German company, which patented it, wants to introduce the methodology in all areas of industry. They can cover almost any surface up to metal and glass, for example, the windshield of a car.

Important! The liquid glass coating of the exterior of the car is not compatible with the subsequent treatment with detergents containing abrasive microparticles.

Polishing a car with liquid glass do it yourself

If you are thinking to independently make the application of liquid glass on the car, you should be familiar with its composition. It contains the following chemical components:

- potassium silicate;

- silica;

- sodium silicate;

- special impurities that provide the desired physical qualities.

Due to the available substances, potassium silicate and sodium silicate, water glass, according to some characteristics, is similar to silicate glue. Silicon additives provide the interaction of polishes with a paint coating. Moisture can get on the car, and polishing a car with liquid glass containing impurities prevents the formation of corrosion centers on the treated surface.

Before you get to work, the car must be put in order. It is necessary to thoroughly clean the entire body of possible contamination: wash and wipe. If the car has already been polished in previous times, then the old layers must be removed with a special paste.

Covering the body with liquid glass is applied only to cold parts, so if the machine is hot, it is better to delay processing until the coating is completely cool. This can sometimes take at least one to two hours. The room where the car will be polished is selected warm and dry. Inside there should be no dust and direct sunlight.

See also: How to paint the car yourself

It is very important that the building is well ventilated to ensure good ventilation for the safety of motorists. Favorable temperature is not less than 10 ° C, but not more than 40 ° C. The ideal temperature is +20 ° C.

Remember that the quality of work depends on the durability of the layer.

Processing auto liquid glass, the pros and cons

The types of pre-polishing used are as follows:

- protective;

- abrasive.

Protective polishing - this is the application of protective polishing paste on the car body for the purpose of additional protection from the environment. Protective polishing pastes are based on wax, Teflon, natural resins.

Abrasive polishing necessary to update the car body, if we are talking about giving a spectacular look to the old paintwork or removing the vehicle color errors. They are recommended to be removed with appropriate tools and materials for the new silicate coating.

The advantages of coating with liquid glass include:

- bright shine creates an optical mirror effect;

- protects against external factors: weather, mechanical and chemical;

- high resilience does not allow moisture and dirt to linger on the surface;

- high percentage of wear and strength;

- effectively removes minor defects in paintwork in the form of scratches, abrasions, cracks;

- protects the metal from corrosion;

- guarantees full transparency, shows all the juicy color saturation of the car for a long time;

- resistant to heating the surface of ultraviolet rays;

- polishing ensures surface anti-electrical layer;

- long service life (up to 1-1.5 years), if compared with other types of polishing agents;

- evaluating the duration of the effect, it is quite an acceptable cost of the product, unlike ordinary polishes.

There are not so many disadvantages as advantages. But they also deserve separate consideration:

- Careful body preparation and proper application of the starting material to the surface part is required.

- It is necessary to comply with certain requirements, such as the need to wash the car with gentle chemical means so as not to wash out the liquid glass. It is forbidden to use alkaline shampoos, washing by using brushes at the sink can reduce the service time by 2 times.

- For the implementation of the process requires an equipped room with ventilation.

Reapply after a certain period of use. After the specified period of use, the effect of the protective composition will end, and all micro-scratches will appear again. Abrasive deep polishing will help to get rid of them.

Stepwise processing algorithm

Abrasive polishing предназначена для реконструкции кузова машины, с небольшими царапинами и другими погрешностями, только если лакокрасочное покрытие старое, однако дефекты еще не затронули уровень грунтовки. До того момента как вы приступите к работе, транспортное средство надо привести в порядок. Если автомобиль не новый, первое, что нужно – обработка поверхности полировальным кругом.

Then carefully carry out the following operations:

- body treatment of all micro pollution;

- flushing the entire surface;

- drying, which does not allow mechanical impurities;

- degreasing and subsequent rubbing;

- if the transport body was exposed to polishes, then the previous layers must be removed with a special paste.

It is important to consider that the described product is available in two color variations: for cars of light and dark shades. Therefore, it is better to purchase a tool that is suitable in color.

Liquid glass can be two-component and one-component. The latter type is cheaper than the first. Two-component consists of polish and hardener, which are mixed using a pipette included in the package. Next, the mixture is thoroughly shaken.

See also: Repair cracks on the windshieldCovering the body with liquid glass should be applied only to chilled parts. Favorable temperature not less than 10C, then the drying procedure will be approximately 20 minutes. When the value reaches 40C, drying time will be reduced to 10 minutes.

Do not try to completely rub the entire machine in one go. It is better to divide the surface into independent squares. First, it is recommended to paint the bumper, then one of the wings of the car, and so on. The main thing is not to give an opportunity to dry up the polishes before the time, since it will be difficult to rub it in.

When the work is ready, for a complete autopolymerization of the coating, leave the machine for at least a few hours. After applying this substance, liquid glass begins to interact with the paint. Over the next 10-15 days, try not to wash the car.

Processing popular brands of liquid glass

Especially popular and proven brands for such works are the polishes of one-component liquid glass of the Japanese company Wilson - Wilson Silane Guard and two-component AQuly. It was Wilson that made its changes to the composition of liquid glass, replacing the silicates in it with silicon dioxide.

The process of using single-component glass Wilson Silane Guard consists of a component of silicon and hydrogen, which forms a durable protective film. It is also applied with a special sponge, which is included. It is important to know that not all the car can be treated with liquid. It is not recommended to apply this substance to the products:

- from plastic;

- on car bumper;

- rubber or chrome parts;

- glass surfaces and headlights.

We are waiting, as it should be 10-15 minutes, until the applied preparation becomes matte and wipe dry with a napkin also from the kit. After a little effort with a rag, the composition is activated, and as if he is stretched himself on the surface, filling up all the damage. You can process one machine in three or four layers, and see the brilliance of a superior result, which can be obtained only in specialized services. As a result, we get a good value for money.

On the fourth layer of Wilson Silane Guard, we get the desired result. Therefore, layering is welcome. Here, a direct relationship between the level of the layers and the gloss is monitored, since each subsequent layer smoothes out the irregularities. The thickness of the layer provides a guarantee of results.

AQuly two-component liquid glass for automobiles is more expensive and involves several stages of working with this type of liquid glass with the bundled tools. Preparation of material for work will require the following tools:

- basic composition of liquid glass;

- hardener;

- pipette with which substances are mixed;

- fiber;

- towel;

- soft sponge.

The application is carried out in an even layer on the surface gradually, without jumping from one place to another. Rubbing with a soft cloth in a circular motion, making sure that no dust particles fall. Work takes no more than 3-4 hours. I offer these service stations from 10 thousand rubles, so self-processing will save a lot.

Of course, each person decides how to protect his car, the main thing is that he properly courted him. And then your iron horse will delight you and others with its appearance, remaining in excellent condition.