The main node in the car is the engine. It consists of two basic metal elements: the cylinder block and the head. In order to ensure maximum tightness of the working processes of the motor, a technological insert is used between the block and the head - a special gasket.

It is important to monitor its performance, since the operational characteristics of the engine as a whole depend on it. Therefore, if the head gasket is broken, the signs of such an event should be known to every driver. Otherwise, a breakdown may disrupt not only the operation of individual components or systems, but also completely disable the engine or even lead to a traffic accident.

Content

- 1 What is the cylinder head gasket

- 2 Ways to check and causes of failure

- 3 Popular Symptoms

- 4 Timely replacement of the cylinder head gasket

- 5 Choice between paranitic and metal gasket

What is the cylinder head gasket

Inside the cylinder block (BC) there is a system of branched technological channels through which coolant circulates. Their outlet openings are located opposite the similar holes in the head. Antifreeze moves under a certain pressure in the system, therefore no gaps in the interface of metal surfaces are allowed.

Sealing is assisted by an installed gasket. It is securely clamped between flat planes with the help of tightening bolts. In the automotive industry there are these types of gaskets:

- paranitic, which includes asbestos material, sealing / reinforcing components, etc .;

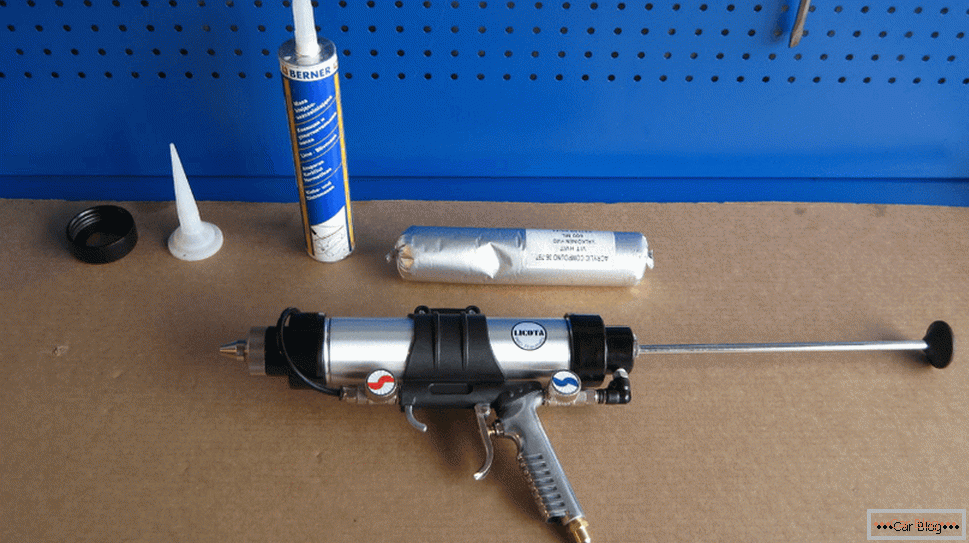

- metal, assembled from several layers of metal, between which is filled with heat-resistant sealant.

Do not allow the cylinder head gasket to burn out. This will lead to undesirable consequences. However, in cars with high mileage, this can happen under various circumstances. Riding with this problem is not worth it, as it can lead to unpredictable consequences with the management and performance of the car.

Ways to check and causes of failure

The driver must take into account that the operation of a vehicle with a faulty gasket in the engine, even during short-term driving is not recommended by experienced drivers. Ignoring the fact can lead to an immediate need for major repairs, which will end up being more cost-consuming than replacing a breakdown.

It is important to know the signs of a punched cylinder head gasket are manifested in very similar facts of both the gasoline engine and the diesel unit, regardless of what type of power plant: atmospheric or turbocharged.

The situation requires a competent, timely and attentive diagnosis. If a head gasket is burned out, symptoms may appear in the following factors in the early stages:

- there will be much more fuel spent on travel;

- engine start will be more difficult or long;

- the engine exhibits unstable work under load and at idle;

- become noticeable in the form of lowering power parameters;

- Coolant noticeably leaves the expansion tank, and it needs to be regularly refilled.

Also, the driver will be able to make sure that the cylinder head gasket has struck, if the effects of measuring compression show that it falls in the cylinders. The most common reasons why a sealing element loses its operational parameters include:

- Incorrect initial installation after replacement;

- substantial heating of the motor, leading to thermal deformation;

- carrying out incorrect tuning to increase the power parameters of the power node;

- the occurrence of detonation when driving on poor-quality fuel;

- Tightening nuts or bolts was carried out with improper force or without the use of a torque wrench.

In most cases, overheating of the motor leads to the problem. This operational state appears for various reasons. The culprit is often a malfunction of the cooling system, or the glow ignition is manifested in the form of increased detonation.

It must be borne in mind that excessively increased temperature almost equally does not tolerate both asbestos and metal gaskets, blowing and losing the strength of their constituent components.

By indirect signs indicating the imminent replacement of the paranitic insert, there can be a noticeable warm-up of the engine. This is a consequence of the penetration of hot gases from the combustion chambers into the cooling system with antifreeze, heating the liquid. Thus, the cooling processes are blocked, which accelerates the heating of the metal and the strengthening of negative related processes, one of which is the thermal deformation of the cylinder head.

Popular symptoms

When the cylinder head gasket has broken through, the symptoms are noted in the form of the following events and events:

- visible or perceived breakthrough of exhaust gas from the joint in the area of the gasket;

- various smudges from the gap between the head and the block;

- the presence of even a small amount of emulsion in the crankcase or lubrication of the motor;

- white smoke often appears or stably holds while the engine is running;

- oil or exhaust gas enters the cooling system.

Since you can check the cylinder head gasket indiscriminately by indirect signs or by ear, you should listen to the work of the power plant. A clear sign of the problem is an increase in noise at different speeds. The release of visible gases is a very rare phenomenon, but it is fairly easy to determine the presence of a problem.

Chip or cracks in asbestos allow the oil from the lubricating system to mutually penetrate into the cooling system with antifreeze and coolant back into the oil. Pay attention to detail and diagnose is the following ways:

- It is worth paying attention to the dipstick, removing it for inspection. It should not be present white-brown foam, as this is a consequence of mixing oil and coolant. Antifreeze when mixed with grease lowers its characteristics, making it unsuitable for further use.

- In the cracks or breakdowns of the coolant can penetrate into the engine cylinders, worsening the operation of the fuel-air mixture. As a result, together with the exhaust comes out of the pipe light smoke. At the same time, the level of antifreeze in the expansion tank is reduced. This effect is not typical for the early stages, but for more serious gasket holes. Also, the presence in the working cylinders of antifreeze can lead to hydraulic shock, because it includes up to 50% distilled water.

- Identify a punched gasket will succeed by such symptoms as oily stains on top of the fluid in the expansion tank or when you open the radiator cap. In more serious cases, the problem can be identified by the appearance of air bubbles in the tank or radiator during engine operation. They represent the exhaust gas that has penetrated the cracks.

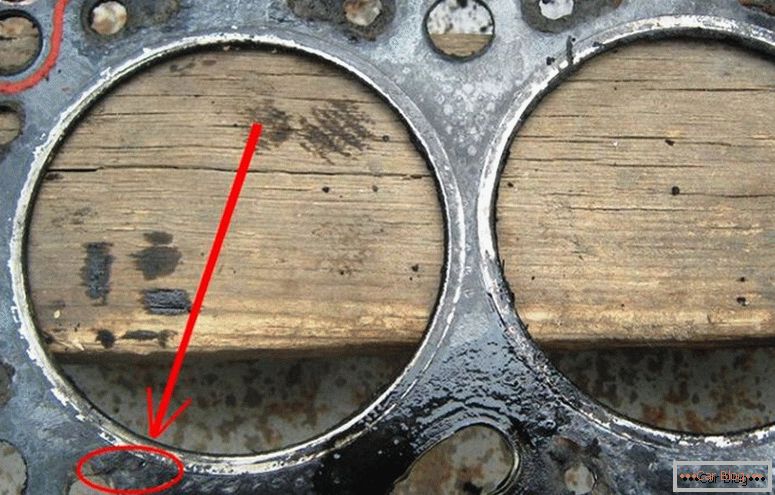

The most problematic is the moment when the cylinder head gasket is broken between the cylinders. A localized problem is detected by indirect criteria:

- motor starts troit;

- fuel consumed more;

- power is reduced.

In such a position, the mixing of exhaust gases from one cylinder with the prepared fuel-air mixture in other cylinders often occurs. This is manifested by unbalanced or unstable work in cold idle mode, but normalization is obtained after some warm-up.

It is worth considering that similar symptoms can manifest themselves with other fundamental factors. In this situation, a more accurate diagnosis is measured compression on the cylinders. When identifying similar lower values for the parameters in adjacent cylinders, it is worth thinking about a more thorough check, for example, visual.

Timely replacement of the cylinder head gasket

The procedure is often a time-consuming process on some models of cars. In most cases, it is necessary to drain technical liquids and to open / turn off certain components. After dismantling, it is worth testing the degree of flatness of the head surface with the appropriate devices.

Mating sides must be cleaned of possible dirt and soot. Deep scratches, chips or other mechanical defects are not allowed. Often, in order to hide small thermal deformations, the surface has to be polished with appropriate equipment. If a significant layer is removed, then it will be necessary to select a “repair” gasket of increased thickness, compensating the cut metal layer.

In the process of tightening the head bolts during the installation after repair, it is necessary to observe not only the force, but also the order of use of fasteners set by the manufacturer. For screwing apply a special torque wrench, indicating the degree of force applied. Do not over-tighten, as this will lead to breakage of the studs.

Failure to comply with the tightened force leads to loss of tightness of the system, since there is no tight fit both due to the stud / bolt breakage and to the formation of a gap between the head and the block. Experienced experts recommend binding fasteners several tens of kilometers after installing a new gasket.

It is important at the initial stage to monitor the state of tightness and the operation of the motor with a new gasket. In this case, the exhaust must be free of impurities, the temperature of the motor should be observed without exceeding. Finishing is also done with a torque wrench.

Choice between paranitic and metal gasket

Not all motorists know which type of gasket will be optimal for a car: metal or asbestos based. Seasoned drivers and experienced auto mechanics prefer metal models, because they are designed for more aggressive working conditions. It is preferable to choose metal products when it comes to turbo engines or tuned to enhance the afterburner of power plants.

For classical atmospheres, which had a paranit from the factory and no power modifications were carried out, it is possible to do well with metal-paranite products. The advantage of such models is the optimal smoothing of possible irregularities on the mating surfaces.

An important factor that often has a greater impact than the quality of the material is the correct installation of the gasket. Incorrect laid part with poorly matching holes can soon burn out in the area of cylinders. In the future, this will lead to the negative factors described above.