Spring check

Periodically it is necessary to check the health of the springs on the machine. If body strikes occur on the bridge beam, and the control becomes difficult, then these spring components are worn out.

Before diagnosing the components are all washed. Inspect the details of the springs: detect cracks, damage and wear format. Be sure to fix the elasticity of products for control positions. In the presence of deformation on the springs, we will note a violation of the functional details.

Changes to the design of the car

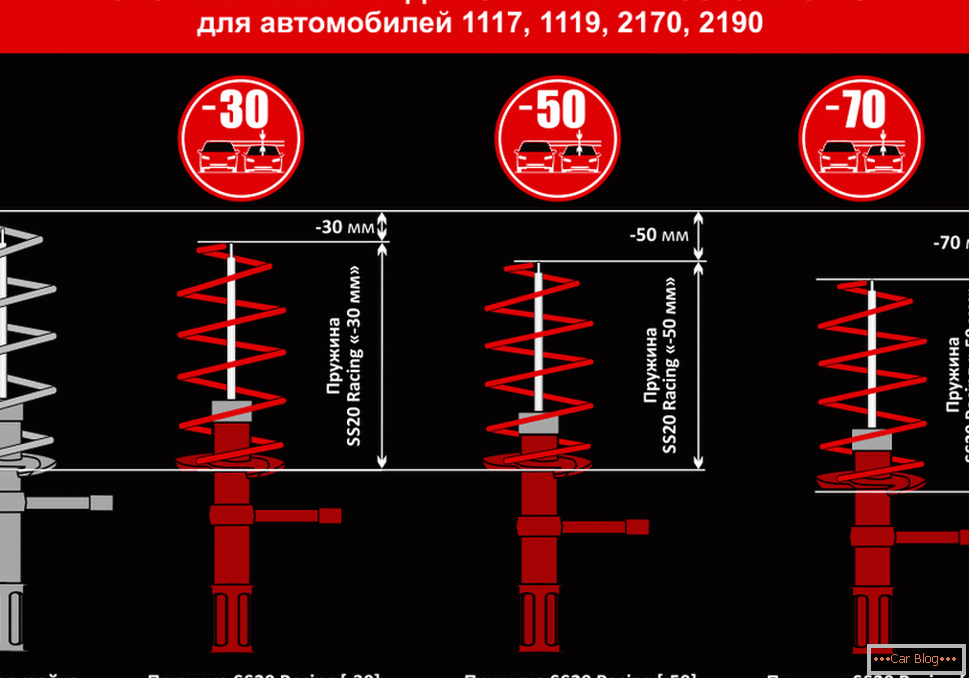

Trying to change the springs, car owners adjust the ground clearance format, the level of rigidity of the product. To reduce clearance, it is enough to shorten the element, cutting off the coils on a standard spring. Before the manipulation is to calculate the consequences. At the spring, the stiffness index becomes inversely proportional to the number of active turns.

It turns out that with the cutting of components, the deformation of the part changes, its length. When the spring is shortened by a couple of turns, the stiffness increases by 33 percent. This reduces the length of the product by 13 percent under load. When shortening the spring, it is not necessary to compare the resource with the standard part. Just the tension increases on the remaining fragments. It is not advisable to cut the springs that were previously used - take new copies. The trimmed end must be supported on the lever cup. If the shock absorbers are standard, it is easy to cut the coil on the rear spring. It will result in a slight “overhang”, but the design will not disintegrate on a suspended wheel. At installation of the shortened springs to put it is required shock-absorber installation with a small rod. Really lower the mount, using the brackets.

See also: How to change the rear rack on the car Cutting the spring, keep in mind that at the end the step of this winding will decrease - you will get a platform for bearing. Removing the coils, this perimeter will also decrease - the tension on the cup will increase. We ensure that the support is even at the spring with the cup, the last turn is released.

Cutting the spring, keep in mind that at the end the step of this winding will decrease - you will get a platform for bearing. Removing the coils, this perimeter will also decrease - the tension on the cup will increase. We ensure that the support is even at the spring with the cup, the last turn is released.

It is enough to heat the installation to six hundred degrees, then cool it in air. Here they use a gas burner, warming up part of the spring. We act carefully so as not to damage the parts.