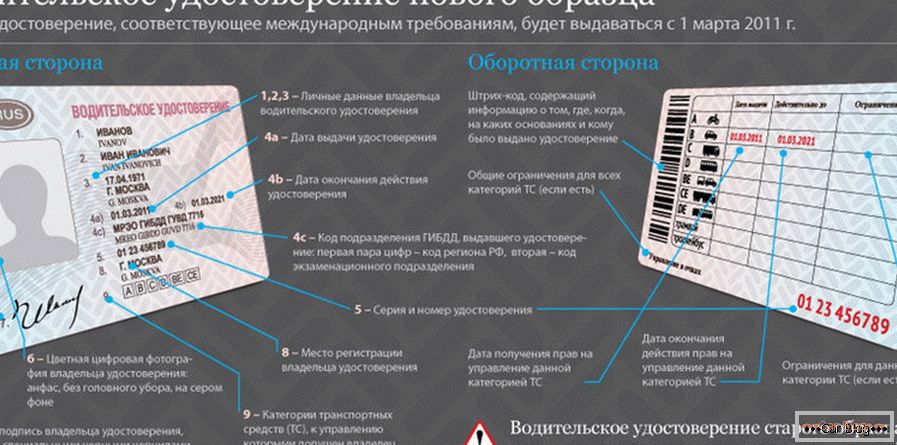

История вариатора насчитывает уже более ста лет. Запатентована эта разработка была в 19-м веке. Но прижилась в автомобилях не сразу, лишь спустя полвека появились первые машины, на которых был установлен вариаторный механизм. Первыми автомобилями с коробкой передач такого типа стали голландские DAF. Но пик использования пришелся на 80-е и 90-е годы прошлого века. Причем не только в автомобилях применялся вариатор, но и в скутерах. Вариатор – это разновидность АКПП, даже выбор режима ничем не отличается от автомата, построенного по классической схеме. Постараемся рассмотреть более детально, what is a variator и как он работает.

Content

- 1 Main nodes of the variator

- 1.1 V-belt variators

- 1.2 Toroidal Variators

- 2 Pros and cons of CVT automatic transmission

The main nodes of the variator

The DAF 600 was the first car in the world to be fitted with a V-belt variator.

There are many types of CVT mechanisms today. But the principle of operation is the same - the gear ratio between the engine crankshaft and the wheel drives changes smoothly. In the automotive industry, two types of gear are widespread:

- Belt wedge-shaped.

- Toroidal transfer type.

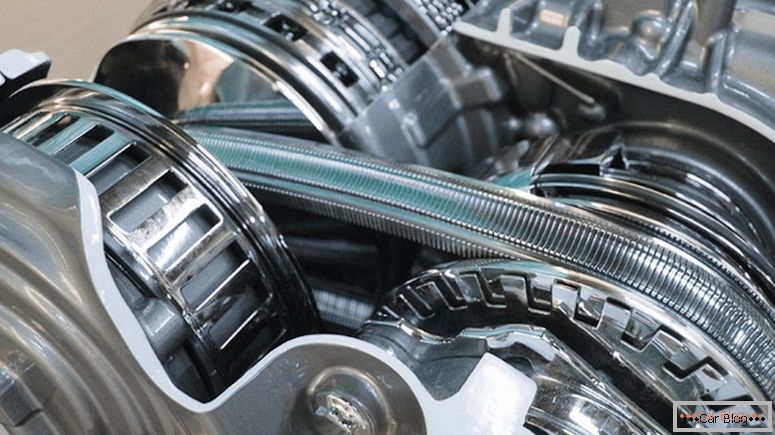

V-belt variators

The basis of the design is two cone-shaped pulleys. Between them, one or two belts are stretched, it has the shape of a wedge - as on the drive of the generators of some cars (for example, domestic classics). Belts are made of high-quality rubber, metal chains or a set of plates. Depending on what material is used in the manufacture, you can judge the reliability and resource of the box, the principle of operation remains the same.

The design is designed in such a way that the pulleys can move or move apart. Due to this, their diameters change. Since the belt touches the side of the pulleys, the life of the mechanism increases - even rubber samples can last at least fifty thousand kilometers. More advanced designs with the use of metal and withstand a longer period.

The scheme of the V-belt variator

The principle of operation of the variator is that the pulleys change position relative to each other - they approach or move away. At low revolutions of the crankshaft, the drives on the drive shaft are unclenched and the followers are compressed. As a consequence, the first have a diameter smaller than the second. When the rotational speed of the crankshaft increases, there is a gradual unclenching of the driven disks and compression of the leading ones. In this case, the gear ratio becomes smaller.

The electronic variable-speed gearbox control system is based on microprocessors. It ensures that the diameters of both pulleys vary evenly, depending on the load on the car engine. Also, the control system controls the operation of the clutch and planetary gear. It is worth mentioning separately about the planetary type of gearbox, which is necessary when reversing. If it were not for him, then the automatic transmission of a CVT type could not perform a reverse, that is, it would have been impossible to reverse the car.

See also: Pros and cons of a robotic gearboxThe electronic transmission control system allows you to keep engine revolutions at cruising speed that will ensure minimum fuel consumption, as well as good driving dynamics. For many years, many experiments have been carried out, which revealed one feature - the inner walls of the pulleys should have a tilt angle equal to 20 degrees. This is the optimal value, so manufacturers make pulleys of just such a shape.

V-belt variator with a chain of metal plates

Transmission variator type works due to the fact that the pulleys are shifted and moved apart. This is provided by a hydraulic actuator, springs or centrifugal forces. The transmission of torque using a rubber belt, of course, is simple and cheap, but it has shown itself badly, since a resource of 50,000 kilometers is extremely small. Boxes that use chains made from metal plates are much more effective. They have a great resource, and the probability of a break is extremely small. But most importantly - a lot less extraneous noise.

Transmission of torque using a chain is reliable and has high efficiency. This means that there will be practically no losses, all the torque will go from the engine to the wheel drives. The control of such a variator occurs with the help of the mode selection lever located in the passenger compartment. Depending on the brand of car, V-belt variators may vary in design.

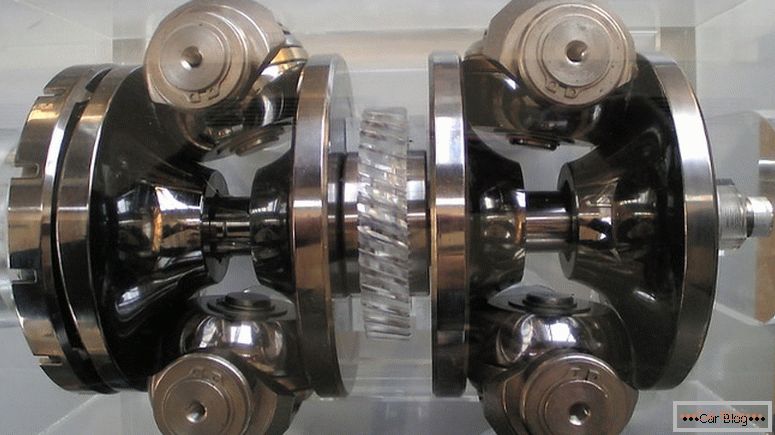

Toroidal Variators

Toroidal variator

This type of variator was less common than the V-belt. The base is a pair of spherical coaxial shafts in which the rollers are clamped. Spherical shafts rotate in different directions. Changing the gear ratio depends on the position of the rollers relative to the surface of the shaft. The rollers transmit the movement to the shafts with the help of friction force only. This gearbox has one big drawback - wear in those places where the roller is in contact with the shaft surface.

It is worth noting that the force with which the rollers are pressed against the surface of the sphere can reach ten tons. It follows that the best materials should be used, and the system should be managed by a reliable and reliable device. As an example, Extroid variators, which are still installed on the cars of the manufacturer Nissan. It has a hydraulic actuator, which is controlled by the control unit. He is able to move the rollers relative to the sphere down to microns.

The principle of operation of the toroidal variator

Pros and cons of CVT automatic transmission

The main advantages, of course, are:

- smooth acceleration;

- simple construction;

- fuel economy compared to the classic automatic transmission;

- low cost (repair and maintenance will not hit the wallet);

- increase in the engine resource due to the fact that its operation occurs in the normal mode;

- low noise level;

- environmental friendliness.

But not to do without the minuses, the main one is that the variable-speed gearbox cannot withstand increased loads. Variators can often be found on low-power mopeds, but on cars with several hundred horses under the hood they try not to install. Although some Audi models are equipped with automatic transmission of CVT type, but using the latest developments that allow powerful engines to work with such a box. So more often you can meet the automatic transmission CVT type on budget cars, the engine power of which is small. And if you own such a machine, you should know that you can pull a trailer if its total weight is small. In the event of a preload, the transmission may be damaged.

Motorcycles use high-strength rubber belts with reinforcement, but in the automotive industry they are useless, metal chains are more reliable. And if you have a variator, then “puff” it will not work. These cars are for those who prefer a quiet ride with smooth acceleration. Yes, there is a “Sport” mode, but with frequent and long-term use of the box elements wear out quickly.

The disadvantages can be attributed to the fact that towing cars with automatic transmissions of CVT type is possible on 50-100 kilometers. So, if there is a need for towing, it will be cheaper to remove the drives in order to safely deliver the car to the right place. But it is also possible by the method of partial loading, if there is such a possibility. As for off-road trips, it is better to abandon them, because this will lead to rapid wear of the automatic transmission.

Замена ремня в вариаторной КПП производится каждые 150 тыс. км, а смена трансмиссионного масла необходима раз в 50 тыс. км. От этого зависит то, how the variator works и его эффективность. И если на мототехнике ремень – это расходный материал, который меняется быстро и минимальным набором инструментов, то в автомобиле такое занятие может быть осложнено тем, что не каждая СТО имеет квалифицированного специалиста, способного проделать всю работу качественно.

But much depends on the electronic control system, it is necessary to closely monitor its work. If any errors occur, they should be fixed immediately. But in general, a car ride with a CVT box is much cheaper than a car with a classic automatic transmission. And this is influenced by the fact that fuel is consumed much less, repairs are cheaper, components in the construction are cheap and simple.