Responsibility for the supply of electricity to the sources of consumption in a vehicle with an internal combustion engine lies on the generator. Without it, it is almost impossible to imagine a modern motorcycle or car. In the article we will reveal the principle of operation of the generator, its main components and elements.

Content

- 1 principle of operation

- 2 Requirements for the oscillator

- 3 Mounting and drive device

- 4 Generator device

- 5 Stater

- 6 rotor

- 7 brush unit

- 8 Rectifier blocks

- 9 Heat Sink Plates

- 10 Bearings

- 11 generator cooling

- 12 Voltage regulator

Principle of operation

When the driver turns the ignition key, electrical energy is supplied to the starter. This device in the first seconds of the car is the only one who is powered by a battery (battery) and helps to rotate the crankshaft. After starting the power plant, the rotation of the engine through the belt transmission is transmitted to the generator.

Almost immediately, the battery from the source turns into a consumer of energy and begins to regain charge. Now the generator becomes a source of electricity when the engine is running.

The principle of operation of the automotive generator is that it receives mechanical rotational energy from the engine and turns it into electrical energy.

In the absence of this device in cars, the battery charge would not be enough for long-term work. But with the generator it turns out not only the absence of discharge, but also the process of charging. Its capacity is enough to work all installed electrical appliances that affect the performance of the machine, as well as increasing the comfort of the driver and passengers.

When several energy-intensive consumers start up at the same time in a car, the power of the generator may not be enough, in which case a battery comes to the rescue. Thanks to such an interconnected system, the consumer does not notice the inconvenience, and both devices create the optimal way for the electric units to operate in the machine.

Requirements for the oscillator

The device and the principle of the generator does not impose certain obligations on the performance of its functions. Basic requirements consist of the following items:

- simultaneous and uninterrupted supply of electricity necessary nodes, as well as charging the battery;

- while the motor is operating at low speed there should be no significant charge withdrawal from the battery;

- the voltage level in the network must be stable;

- the generator must be durable, reliable, with low noise and not cause radio interference.

Mounting and drive device

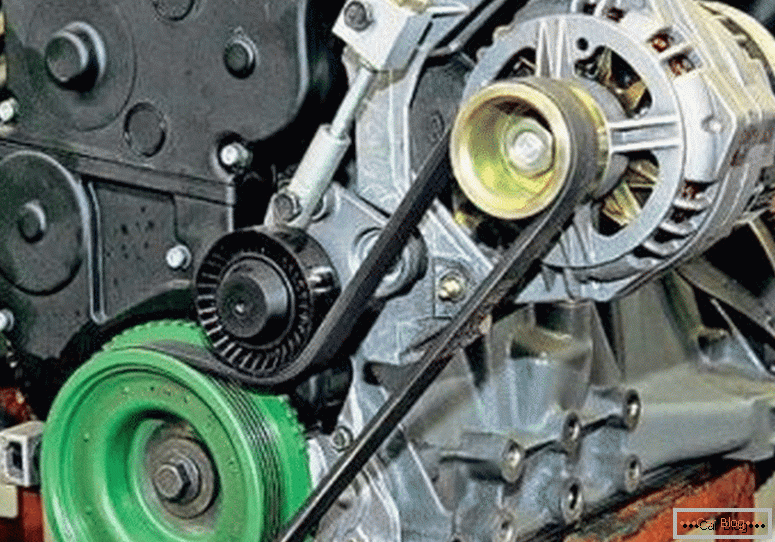

The drive in all cars has a standard look: a pulley mounted on the crankshaft is connected via a belt drive with a pulley on the rotor shaft of the device. The dimensions of the pulleys in the transmission are determined from the need to obtain a given number of revolutions on the generator.

Mounting on the block

In modern cars using ribbed belts. With their help, it is possible to transfer a greater number of revolutions to the generator rotor.

The device is attached to the body of the unit in the engine compartment. A belt tensioner is also installed there. It is necessary to establish high-quality transmission of rotation to prevent slippage of the belt on the pulley. Otherwise, the electricity will switch to the use of the battery, which will lead to its complete and imperceptible discharge.

See also: How to make a stroboscope for cars with their own handsIt is customary to distinguish two groups of structurally different generators:

- devices with a fan near the drive pulley are considered to be a traditional design;

- The design, in which two fans are installed in the case of the device, is considered newer and belongs to compact devices.

Generator device

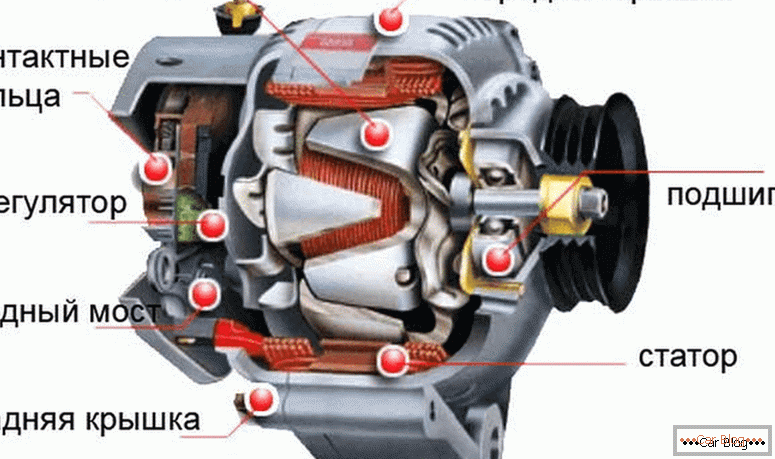

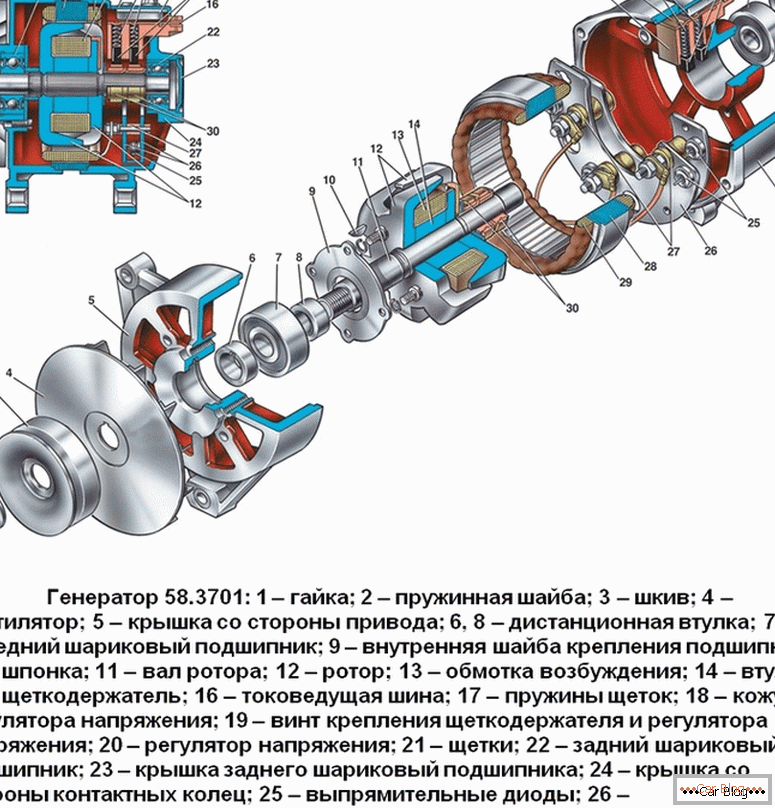

The main parts of any generator are a fixed block - a stator and a rotating structural member - a rotor. The stator is a winding of copper wires. It is fixed on both sides with covers, as a rule, of light aluminum alloys. On the side of the pulley attachment, the front cover, and on the brush side, the back cover.

A voltage regulator is mounted on the back of the brush mechanism. There is also a rectifier unit. Covers fix the stator and fasten among themselves with the help of several screws. Paws, with which the generator is fixed to the car body, are molded with covers. In the same way it turns out the ear tension.

In the hole of one of the legs can be installed sleeve, which helps to adjust the installation of the generator on the bracket, choosing the necessary clearance. Also the ear of the tensioning mechanism is supplied with several openings for installation of the device on cars of various brands.

Stator

How the generator works depends on the quality performance of its functions of each of their blocks. The base of the stator is composed of identical sheet steel elements with a thickness of up to 1 mm. If the stator base (plate pack) is made using winding, the block yoke contains protrusions located under the slots. For such convexity, the layers of the winding are fixed. Protrusions also help to better cool the entire structure.

Stator генератора

In almost all generators, the number of slots is the same. They are usually in serial cars 36. Insulation is carried out between them using an epoxy insulator.

Rotor

For automotive generators, the main feature is the pole arrangement of the rotors. The winding of this node is closed with two stamped metal cup-shaped halves, with protruding beak-shaped petals. They are fixed on the shaft, as if wrapping the winding with these petals.

Bearings are mounted on the shaft, one of the shaft ends is threaded with a keyway and the seat surface is under the pulley.

Generator rotor

Brush knot

Sliding contacts are installed in this unit. In the oscillators take two types of brushes:

- electrographic;

- copper graphite.

In the first case, there is a periodic decrease in voltage at contacts with the ring. This leads to poor-quality operation of the generator, which supplies unstable voltage in such a situation. However, they also have a positive effect, because there is less wear, unlike copper ones.

Rectifier blocks

There are two main types of rectifier nodes:

- in the first case, the diodes are pressed into the heat sink plates;

- in the second case, structural fins are used, in which the diodes are soldered to the heat sinks.

Heat Sink Plates

The closure of such plates is very dangerous for the entire car. The cause of this incident - the pollution that fell between the plates. It may be conductive and close the positive side of the wiring with the negative.

A short between the plates may cause a fire in the car.

To avoid such a development of events, an individual coating of each plate with an insulating layer is carried out on the production.

Bearings

The design uses ball bearings. By production of generators they receive lubricant for all operational term. American automakers sometimes use roller bearings. Landing from the side of the contact group is usually “with a tightness”, and from the side of the pulley, a sliding fit is applied. Reverse logic is used when installing in the seats of the cover.

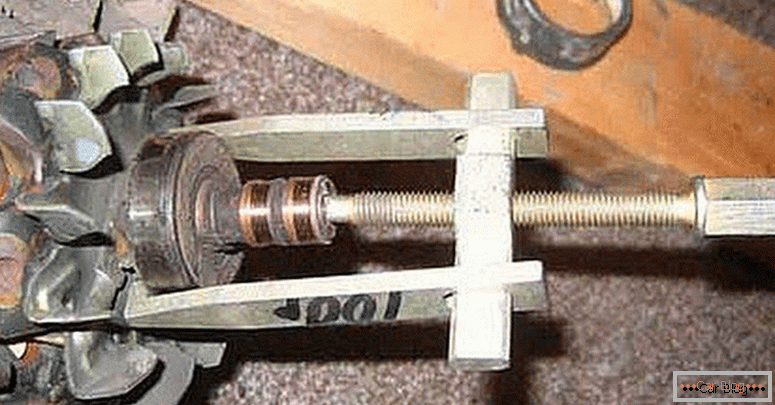

Disassembly of generator bearings

Twisting from the side of the contact group of the outer bearing cage leads to the failure of this mating pair (bearing / cap).

So, the rotor can touch the stator. To avoid this, additional seals are often put in the cap: a plastic sleeve, a rubber ring.

Generator cooling

The lowering of the working temperature is carried out with the help of those installed on the rotor shaft of the fans. The traditional design involves the supply of air to the lid of the device from the contact group. With the external arrangement of the brush unit, the cooling supply is conducted through a protective cover covering the contacts with the brushes.

Cars with a compact arrangement of units under the hood are often equipped with a generator with a special additional cover. The intake of cold intake air is provided through its slots. In generators with a compact design, cooling is carried out on both sides of the covers due to the presence of two fans.

Voltage regulator

Also in all modern generators installed semiconductor electronic voltage regulators. The regulator provides heat compensation. The voltage applied to the battery depends on the engine compartment temperature. The colder the air, the greater the voltage applied to the battery.