Modern cars are hard to imagine without electronics. Most processes in them are controlled by various sensors. The fuel system in this case is no exception. Fuel injection into the cylinders is carried out only after the camshaft position sensor (DPRV) gives the desired command for this operation.

Content

- 1 Work sensor in the car

- 2 Symptoms of a device failure

- 3 How to check camshaft sensor

Work sensor in the car

The principal location of many nodes or mechanisms in the engine circuit in all cars is about the same. However, their physical installation may differ in a particular car brand. Therefore, in order to independently find out where the DPRV is located, you will need to use the atlas or the scheme of the desired car.

The camshaft position sensor maps the camshaft position relative to the crankshaft rotation. The signal of the relative position of these elements is sent to the electronic control system. The next step is to send a signal for fuel injection into a specific cylinder.

You can often hear that such DPRV called Hall sensor or a magnetic field. This is due to the similar principle of their work. After all, when voltage is passed across the terminals of a semiconductor wafer located in a magnetic field, voltage will also appear on its other side terminals. A permanent magnet is installed inside the device to form a magnetic field.

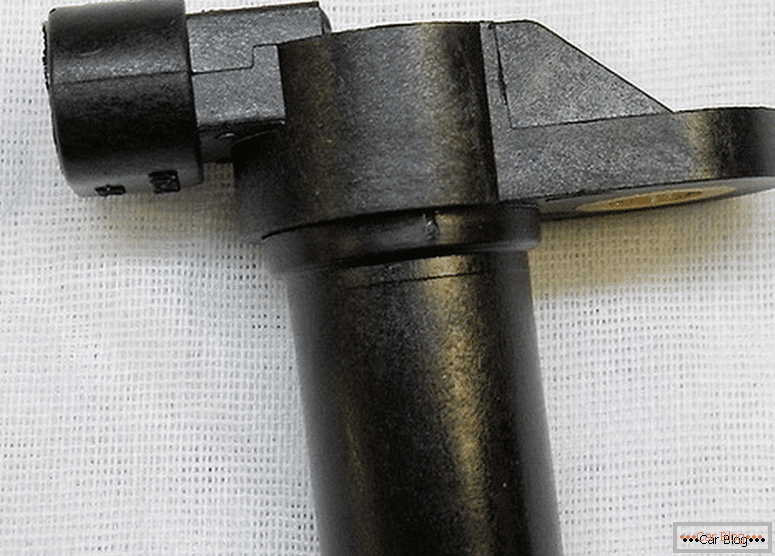

Appearance sensor

The bench mark in the form of a metal tooth, located on the gear, closes the electrical circuit. Passing alongside the sensor, it also activates the impulse transmitted to the control system in the DPRV. Such pulses are transmitted at a certain time interval. "Electronics" their "reads" and gives signals for fuel supply.

Symptoms of a device malfunction

Symptoms of a camshaft position sensor malfunction are as follows:

- deterioration in dynamics with a stable uniform ride, while the signal on the panel “check engine” can light up;

- independent increase or decrease in the number of revolutions engine system without driver;

- unstable work of the heated motor at idle;

- detonation in the power plant with dynamic load;

- substantially the expense rises;

- engine does not start.

The list includes the main symptoms. Although such manifestations do not indicate an unambiguous breakdown of the specified device, but for such signs, an independent primary diagnosis is required.

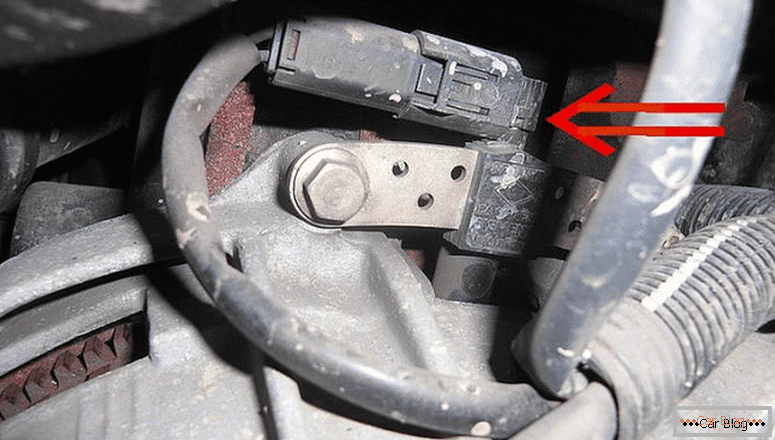

Sensor location

Causes of inoperability:

- the disk with reference points has failed;

- bias installation DPRV;

- a short circuit occurred inside the instrument;

- significant warming up of the motor.

Как проверить датчик распредвала

After a warning about a sensor failure on the dashboard, it is necessary to check it or the crankshaft position sensor. Both devices work interconnected, and the signals from them are monitored in the control unit.

At the stations, DPRS testing is carried out using data output to the oscilloscope. Such a device will indicate all detected sensor faults.

Independently, it is possible to reveal obvious visual violations of the device design. The device has a special external indicator for this. It signals incorrect operation.

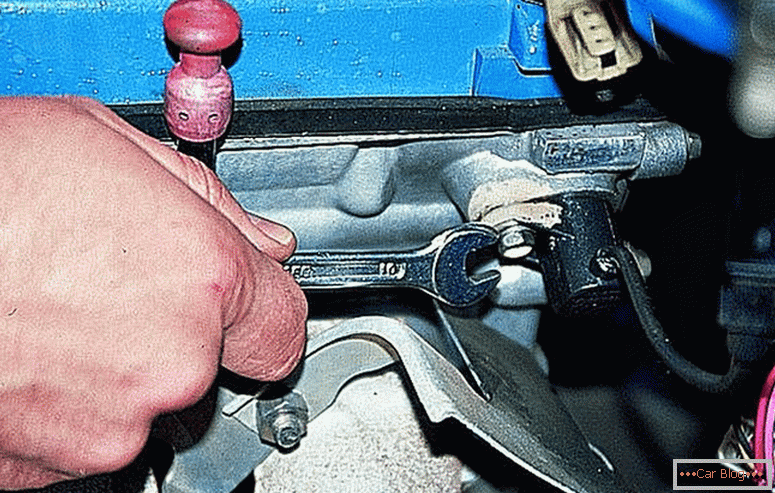

Clearance Adjustment

If the indicator is always on, it can mean such failures:

- damage in the electrical circuit of the device;

- lack of contact with the negative terminal;

- it is necessary to adjust the gap between the marker and DPRV.

As a preventive measure, mechanical cleaning of the surface of the device and its contacts is carried out. You can also check the electrical circuit for breaks or breakdowns. For this operation, you need an electrical multimeter.

If the indicator starts to run randomly when the engine is idling, it is monitored in two positions:

- the presence of face beats of the pin on which the marker is installed;

- poor contact with the mass.

Self-replacement of this device is carried out within a few minutes.

Its cost for an average car will be from 10 to 20 dollars. The sensor is not repairable, so the old and non-working device should not be stored.