Modern cars build their action algorithms based on the readings of various sensors. Most of these devices analyze a parameter and transmit information to an electronic control unit (ECU).

If, for example, there are signs of a malfunction in the coolant temperature sensor (CTO) or another tester, then such devices should be replaced. Incorrect information from them is fraught with disruptions in the operation of the engine and other important vehicle systems. Let us examine the situation on the example of the cooling of the cylinder block.

Content

- 1 Performance CTO

- 2 What processes are affected by the temperature sensor?

- 3 Varieties of Coolant Temperature Sensors

- 4 Detection of the inoperability of the sensor and its possible failures

- 5 Ways to check for performance

- 6 Replacing the coolant temperature sensor

The performance of CTO

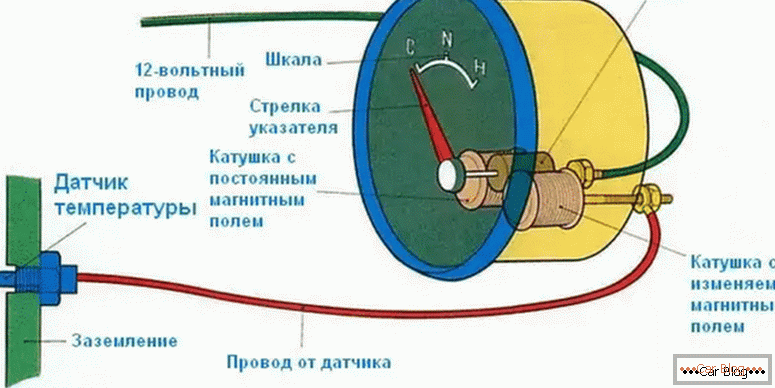

When the engine is running, heat from the engine block is generated in the car. Abstraction of the excess heat is engaged in coolant. It circulates through the channels of the unit, as well as in the radiator. Analyzing what the coolant temperature sensor affects, you need to understand how such a device works. Indeed, its task is to send signals about the state of the engine, guided by indirect data (temperature).

The ECU is informed if the motor is cold, works in the regular temperature ranges, overheating occurs, or the internal combustion engine only goes into operating parameters after the start. Such data are analyzed by electronics, and on their basis the overall operation of the power plant control systems is formed.

By influencing the performance of this sensor, it is possible to increase the controllability of the car when driving on a cold engine, stabilize the idling speed, and lower the level of harmful exhaust emissions. Accordingly, a malfunction of the coolant temperature sensor or the transmission of corrupted data to the control unit will create noticeable trouble.

What processes are affected by the temperature sensor?

Thanks to the signals from this electronic device, automatic commands are formed for such systems:

- Fuel enrichment process. If the head unit receives information about the low temperature of the cooling liquid, then the injection time is counted upwards for the injectors. This action contributes to the stability of work at idle. The temperature gradually increases, and on the basis of such indications the nozzles impoverish the mixture. If the sensor does not give the correct information, there will be a re-enrichment, additional unnecessary costs for fuel emissions, an increase in pollution emissions.

- Increase in turns during start. The motor may stall if the starting frequency is insufficient. To get rid of this helps the team from the computer to accelerate the rotation, so that the car does not stall.

- Exhaust recycling. In order to maintain controllability at the start-up stage, the recirculation valve must be closed before the system goes to operating temperature. If you do not do this, then we get unstable turns or a stalled car.

- Ignition angle. The setting of this parameter should be strictly regulated to reduce the amount of harmful exhausts to the set temperature. From the lead / lag of ignition depends on the flow and output parameters of the power plant.

- Filter statetrapping fuel vapors. It is necessary to purge the carbon filter only when the full warm-up of the motor occurs.

- Torque Converter Clutch in the gearbox is not blocked until the engine is warming up. This is done in order to maintain optimal controllability.

- Turn on the cooling fan. On the basis of data from DTOZH, the fan of the cooling system is started or disconnected. It helps to quickly reduce the temperature of the refrigerant. In some car models, a separate sensor with a single function is used exclusively to start such a fan.

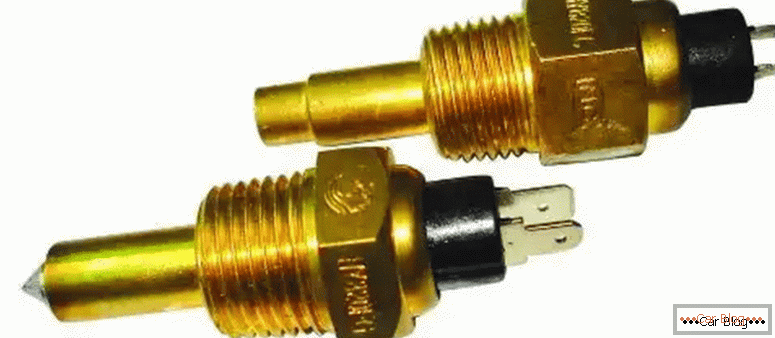

Varieties of Coolant Temperature Sensors

Most often, a thermistor is used as a working tool. He is able to change the resistance in the electrical circuit with changes in temperature of the environment in which it is located. Commonly used materials in which the electrical resistance decreases when the liquid heats up.

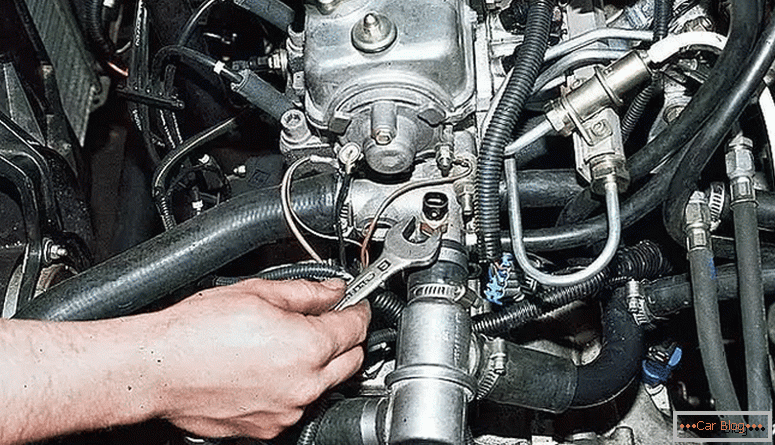

How to unscrew CTO

When it cools, the resistance of the coolant temperature sensor increases significantly. Based on these readings, the signals are sent to the ECU.

As examples, consider the sensors General Motors. At temperature 0With it has a resistance of 10 kΩ. If the coolant warms up to about 93 during engine operation.C, then the thermistor index is reduced to 0.2 kΩ. The company Ford DTOZH at OC has a parameter of 95 kΩ. When entering the operating temperature of the power plant with 93With the resistance level comes yes 2.3 kΩ.

From these readings it is clear that the characteristics for different automakers are set individually. Therefore, choosing a new sensor in the store, it is necessary to take into account the automotive brand and the specific model. Otherwise, the readings of the new device and its signals may differ significantly from those planned for a specific ECU.

You need to know that the temperature gauge for the coolant must directly touch the refrigerant.

There is a CTO, as a rule, in the intake manifold near the thermostat installed in the same place. Less commonly, designers place this sensor closer to the cylinder head. With a V-shaped arrangement of cylinders, engineers assemble a pair of CTP for each row of combustion chambers. A pair of sensors can also be placed separately for the fan and the ECU.

For the accuracy of the readings of the electronics in the system there should be a normal level of refrigerant. With a lack of cooler, malfunction of the CTP is possible. Therefore, you need time to add coolant to the system.

Detection of the inoperability of the sensor and its possible failures

Many systems rely on the readings of the thermal sensor, so its unfair work entails a chain of erroneous actions of automation and incorrect operation of the motor. Such problems can quickly disable individual parts and entire assemblies.

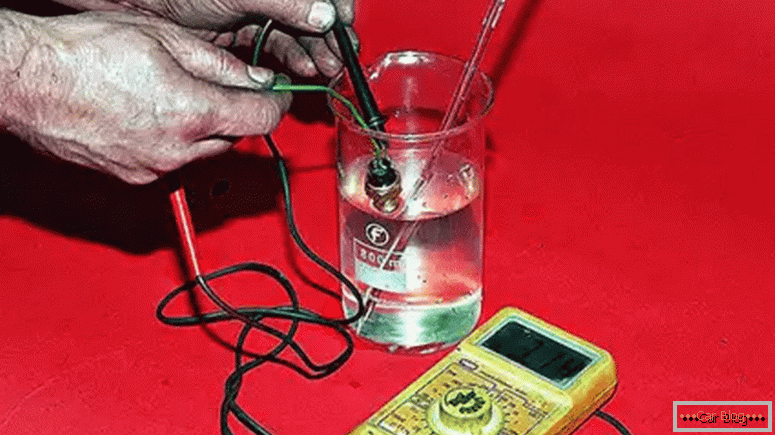

Checking the coolant temperature sensor

You need to know that most of the problems, as experience shows, are not connected with the breakdown of a CTP or its internal problems, but with troubles with wiring or a rusty or untight connection in the system.

One of the factors influencing the work of a thermal sensor is a thermostat. Starting the refrigerant constantly in a large circle, even on a cold engine, will not allow the engine to go into operating temperature for a long time. This will lead to additional fuel consumption, intensive wear of parts of the power plant, increased emissions and other problems.

When inspecting the installation of DTOZh can independently identify possible faults.

Worry is with such signs:

- the presence of damage to the thermal sensor case (cracks, chips, etc.);

- refrigerant leakage (visible drips, the presence of droplets around the compound, dust sprinkled with dried drips);

- oxidation around the threaded connection (problems with unscrewing the sensor, even incompletely).

However, even with such defects, the appliance may be in working condition. The reason may lie in the inconsistency of its electrical output parameters.

You can check using a multimeter. Readings should be compared with the reference values for each model of car. If there is a short circuit, incorrect output data or contact failure, the device should be replaced.

Scheme of work

When the test revealed the efficiency of the sensor, the correct reaction to temperature fluctuations, but the motor continues to operate with an open loop, not paying attention to the signals from the CTP, then you need to identify problems in the electronic control unit.

Ways to check for performance

Two devices will help to control the output parameters:

- digital oscilloscope with memory function;

- voltmeter with electronic scale.

You need to be guided by the value of 3 V. When the motor warms up and the temperature increases, the voltage will drop to 1.3-0.5 V. The oscilloscope will reach these values in 4-5 minutes.

When testers show a voltage of less than 5 V, this indicates a loss of reference voltage or a short circuit. Some sensors have a high / low function. During testing, there will be abrupt changes in voltage with increasing temperature. On the received oscillogram data, the short-circuited moments will be in the form of a fall to zero, and breaks in the circuit will be indicated by an increase in voltage to 5 V.

In the case when the output parameters of the CTO are normal, and the temperature in the system does not go into operation, the cause of the malfunction most likely lies in the thermostat. His chain remains in the open position, and the refrigerant does not heat up to the temperature set by the automaker.

Coolant Temperature Sensor Replacement

Drivers rarely pay attention to this element of the system until the internal combustion engine malfunctions. Actions begin only ambassadors of his breakdown. However, DTT is recommended to be replaced with each disassembly of the engine, because during operation the temperature sensor is exposed to intensive wear in aggressive conditions. Worn out the device may give the wrong signals or with an error. You can get rid of this only by replacing the device.

In addition to repairing the motor, it is recommended to change this electronic indicator along with the thermostat. after significant engine overheatingduring which both elements of the cooling system usually fail. When replacing, the refrigerant must be drained to such an extent that its level drops below the sensor hole.

Simultaneously with the replacement of the sensor often update coolant. Her term of work is usually about 3-5 years. The contaminants dissolved in it can distort the transmitted data, and they also reduce the efficiency of the entire system. Thread before screwing it is accepted to grease with sealant. After installation we fill new coolant.