A large number of vehicles off-road models on domestic routes often indicates the desire of drivers to move in extreme conditions. However, such travel is fraught with the loss of aesthetic appearance. As a result of such activities, chipped paint, scratches and other undesirable effects appear. To minimize or completely get rid of the described phenomena helps painting a car with a raptor with his own hands.

Content

- 1 What will be the result

- 2 Features of the original appearance of the car

- 3 Preparatory operations

- 4 Preparation of paint and varnish solutions

- 5 painting process

What will be the result

The paint and varnish market is rich in various means providing various types of exterior coatings for vehicles. They block the interaction of metal elements with negative factors, which include such phenomena:

- moisture;

- ultraviolet;

- minor mechanical effects;

- oscillations, etc.

By applying the Raptor coating with their own hands, the car owner forms a strong polyurethane layer outside, taking care to prevent body defects for a long period. Such paint is not afraid of pollution, prolonged exposure to the sun, and even exposure to chemical reagents, which are used in large numbers by public service workers.

As a result of processing the surface is matte and slightly rough, like an orange peel. There is no gloss that does not interfere with the appearance of being aesthetic and original. After the work has been done, the machines are not polished, since this process will only damage the protection.

Features of the original appearance of the car

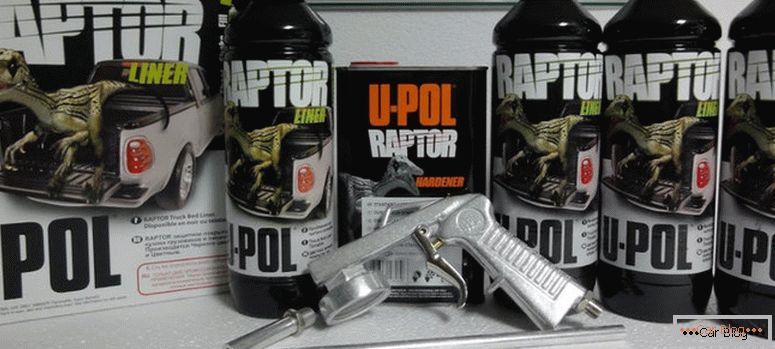

It should be borne in mind that the product from the company U-POL, which has the full name U-POL’S RAPTOR TRUCK BED LINER, was originally intended for processing work platforms of cargo compartments in pickups or trucks. However, the excellent characteristics of paint ensured its success in various industries, which sometimes do not even concern cars.

The material is a two-component composition that includes the paint base directly and the company hardener. The base is a polymer urethane solution, giving maximum strength to the product. With all the strength characteristics of a thin film in the form of an orange peel has a high degree of plasticity, which does not allow it to collapse with the possible resistance from impacts.

As a result, the user gets a surface that has a considerable number of positive parameters:

- the car has an original appearance, which is recognized in the traffic flow;

- the existing texture prevents corrosive foci from water, salts and active chemicals;

- the layer does not fade from sunlight;

- Raptor painting technology is available even to non-professional specialists in garage conditions, subject to the rules for handling the material;

- the layer resists abrasion with time and is not even damaged by scratching with branches;

- applied rough paint serves as an additional sound and vibration absorber when applied in the gift space and under the bottom;

- after blowing out of the cargo compartment floor with such paint, the resulting texture will become an obstacle to the sliding of all kinds of goods.

Staining with the Raptor is also carried out in places subject to active wear.

Preparatory operations

Before painting the machine with the Raptor, it is necessary to do some preparatory work. The importance of this stage is difficult to overestimate, because with poor-quality processing a new layer may not give the desired result.

See also: How to cook a semi-automatic bodyFirst of all, the base is cleaned almost to bare metal, paying particular attention to possible corrosion centers or places of peeling of old paint. Cleaning is carried out using grinders or drills and special forces. Drawing can be carried out over old paint after preliminary grinding.

If sanding paper with sanding paper is supposed to be used, then we recommend taking the material of type Р120-Р220. Sometimes you have to use and P80. These abrasives have larger grains than those commonly used in traditional prepainting.

Do not pay attention to small grooves after cleaning. Raptor thick consistency will hide such micro-irregularities. In this case, it will be safer to keep on such a body, filling the grooves. In problem areas it is worth applying a scotch-bright red in order to fully get rid of glossy areas.

Hard to reach areas may not be easily accessible for grinding. For such zones, the company-manufacturer of modern chemistry provides for the dispersion of the GRIP # 4 adhesive amplifier. It is offered under the name UNIVERSAL ADHESIONPROMOTER. Manufacturers recommend this composition as a preliminary basis for plastic, which eliminates the need for pre-grinding.

It is important to know that before applying the Raptor, the surface should be degreased and cleaned of small particles formed from grinding.

Experts do not recommend processing the “bare” metal body. It should be at least a layer of primer. The preferred material is ACID # 8, manufactured by U-POL. Etching primer is based on epoxy resins. After applying it is important to wait for the complete drying of the composition.

Acrylic one-component soil from cans during processing is not allowed. Also it is necessary to take into account that the paint will not hide large irregularities, therefore they will have to be puttied in advance and put in order by primers.

In order to paint the Raptor with a roller or sprayer, do not touch the unwanted areas, a masking tape is used. It blocks the open areas of the car, including glass, rubber, plastic, which are not intended for processing. Masking is removed no earlier than half an hour after the end.

Preparation of paint and varnish solutions

The main color tone for the Raptor is black. About half of the cars painted in this color. The company also offers in addition to BLACK, a tinted version of TINTABLE. To the latter, you must add the desired color component of the desired pigment.

It is important to know that when applying paint with a roller, it is necessary to purchase an appropriate kit called ROLL-ON RAPTOR.

Mixing is carried out in accordance with the instructions in a ratio of 3: 1 paint and hardener. For convenience, the packaging is performed in containers of 0.75 l (paint) and 0.25 l (hardener). It is not necessary to take for the process the usual solvents, as they will not give the necessary effect.

Stirring takes 2-3 minutes. Color fillers are added to the collated solutions in the ratio of 10% of the total volume.

See also: Local repair of chips and scratches on the car body: how to clean do it yourselfPainting process

It is not advisable to choose a protective anti-primer coating period when the ambient temperature is too hot or frosty. The best conditions will be 20With and humidity close to 60% and below.

When working in closed conditions, we recommend using a respiratory mask or moving the process to an open area. The main toxicity is not contained in the paint, but in the applied proprietary solvent manufactured using toxic isocyanates.

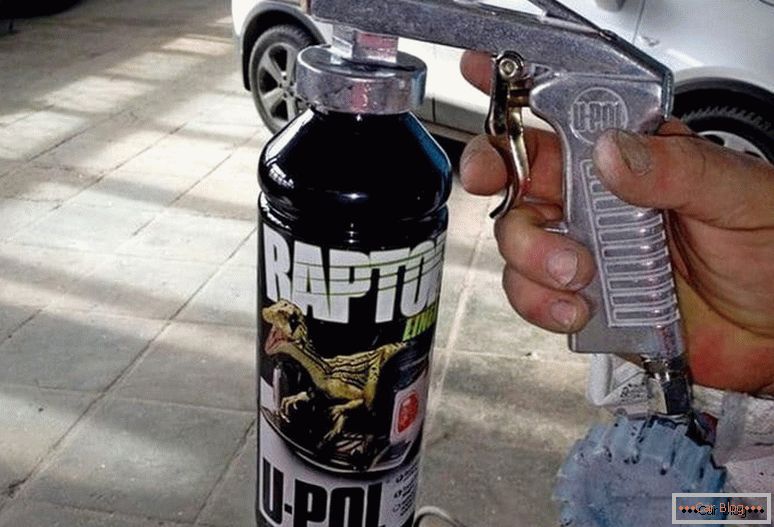

For spraying, it is common to use special Schutz pistols and HVLP spray guns. It is not forbidden to apply with a brush or rollers. If you have the opportunity and desire to get quality tools for work, then you should look for a spray nozzle with an adjustable nozzle RAPTOR PROFESSIONAL VARI-NOZZLE APPLICATION GUN, with which you will be able to create different texture.

After the workpiece is thoroughly mixed, we attach the bottles to the compressor dispenser. Depending on the preferences in the texture, adjust the pressure in the range of 2.5–5.0 atm. In the lower range, the texture of the pattern will be larger, and with an increase in atmospheres, the orange peel will become less prominent.

It is important to know that in addition to pressure, the amount of thinner and distance from the surface to be treated affect the texture. The farther the distance, the less prominent the result.

When adding a diluent to the finished solution, it is possible to influence the texture, in the direction of reducing its relief. Do not mix it more than 10%. The use of branded or universal acrylic composition. Classical solvents, for example, 647 or its analogues will reduce the durability of the result.

Experiment better on third-party surfaces, rather than on the car. Or you can choose the inner side, hidden from view. Spray interval select from 45 to 150 cm. Most often, experts work up to 55 cm.

All work with the finished composition must be completed no later than 60 minutes. When the interval between applying two layers reaches 5 hours or more, it is worth polishing a little foundation.

It is customary to impose 2-3 layers, no more. A sufficient interval between application is 60 minutes. When changing the bottle, it is important not to let the solution harden in the gun, but thoroughly rinse the instrument from the composition with a solvent or acetone.

Drying off-time takes no more than 60–70 minutes. Next, we expect 2–3 days for the train to “grab”, after which the machine can be carefully used in a non-extremal mode. However, full visible hardening occurs within 7–9 days.

In extreme mode, you can operate the car no earlier than in 3-4 weeks. Some experts speed up the drying process by raising the temperature to 60C. The use of infrared dryers is strictly not allowed. It is preferable to provide natural conditions for the solidification of the composition on the surface of the body.