During the application of the aggressive method of driving there is an active wear of the systems and mechanisms of the car. It is important to control in this case the production of elements responsible for safety, in many respects this relates to the braking system. In addition to the wear of the friction linings, there is an erasure of the metal disk with which they are in contact. This means that the responsible driver must know how to remove the brake disc from the hub to replace it.

Content

- 1 Need to replace discs

- 2 Preparatory operations

- 3 Replacement process

- 4 Final operations

Need to replace discs

The regulated period, which is set by the manufacturers to replace the disc, is not always available for car owners. In most cases, this parameter is controlled by the operating time for each car. Replacement is carried out in identifying negative indirect signs. The main problem symptoms are:

- strong creak while pressing the brake pedal;

- lengthened pedal during pressing, the appearance of failures;

- a noticeable decrease in brake fluid, which can be seen in the level in the expansion tank;

- pressing the brake pedal, the driver feels that the car is being led to the side or a beating occurs.

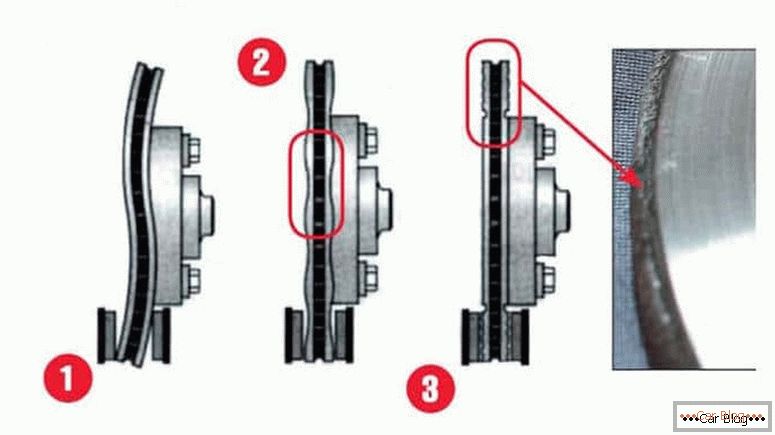

If such signs appear, a diagnostic inspection should be performed. It is advisable to monitor at each wheel in order to have a complete understanding of the state of the brake system. In many cases it will be enough to replace the pads. However, if there are obvious signs of production on the metal surface or the thickness is below the limiting parameter, then you will need to remove the brake disc to replace it or partially restore it.

Preparatory operations

You can dismantle the old drive and install a new one yourself, even in garage conditions. First you need to buy suitable for a particular car model wheels. This should be done carefully, as sometimes even the year of production of the same car affects the installed parts.

To stop the choice on any particular manufacturer of these parts is based on the driving style of the car. Required characteristics for a driver applying an active style with frequent use of a brake pedal or for a driver who spends most of his time on a country road will be different.

It is accepted to divide TD on classical (regular) and sports (strengthened):

- In the classical construction, malleable cast iron is machined to the desired dimensions. Non-ventilated and ventilated items are available. In the first case, the basis is a single disc, next to which a caliper with brake pads is installed. In the second case, a dual system of disks separated by edges is used. Due to the air between them, the unit is ventilated. Popular brands engaged in the manufacture of these parts are ATE, Zimmerman, Bosh.

- By production of the strengthened disks more strong brands of cast iron or the high-alloyed stainless steel are used. These elements provide longer service life at elevated loads while driving. Famous brands in this area offer more expensive products. Most often in auto shops you can find brands such as Brembo, DBA, EBC.

It is necessary to replace the brake discs with a pair on the axle on both sides.

This will ensure proper operation of the entire brake system. Even if one of the sides after a visual inspection is in a satisfactory condition, and the second is significantly worn out, it is recommended to change both disks. If you carry out dismantling work on the one hand, the inconsistency will lead to loss of exchange rate stability. The rule applies to both the front and rear axle.

See also: Diagnostics of the brake system of the car on the standTo carry out installation and dismantling work, you will need the following tools:

- car jack (mechanical, hydraulic, pneumatic);

- structur;

- a hammer with a wooden attachment (a rubber or wooden mallet is allowed), in some cases a reverse hammer is used;

- a set of wrenches and screwdrivers;

- rust treatment fluids (WD-40 or equivalent);

- brake fluid, if necessary, pumping the brakes;

- clean rags and personal protective equipment (work gloves, goggles, etc.);

- brush for metal or power tools with a special nozzle;

- torque wrench.

If the operation is performed on all wheels, then it is customary to change the wheels alternately on each axle.

Replacement process

The repair machine is installed on a straight, flat surface. Jack lift the necessary side and remove the wheel. In the open space free disk for dismantling. Squeeze the piston working cylinder to remove the caliper. Pre-loosen the fastening bolts on it.

It is not necessary to disconnect the hydraulic tubes of the brake system; it is enough to push the knot aside and pull it up with a wire to any beam or thrust. Brake pads unclench and block them with a clamp.

In separate designs of the assembly, the support frame interferes with disassembly. It is enough to unscrew its fasteners and get rid of the interference. In most cases, the mounting bolt clings to and prevents removal from the hub. To weaken it, use VD-40 or brake fluid. Some machines have a pair of such bolts.

Freed from the problematic hardware, you need to remove stuck brake disc. Here you can also use pre-special liquids for corrosion zones. Then you need to apply one of the proven methods:

- Wooden knockout on the back side. This should be done with short sharp blows in order not to create problems.

- A wooden or rubber mallet knock reverse plane. This method is more humane with respect to parts than using a heavier metal hammer.

- Apply reverse hammer. To do this, you need to buy or borrow this relatively rare, but effective tool.

- You can use the puller. However, it is worth feeling the effort not to break the tool or the disk, because in some cases more durable pullers can damage the strongly stuck part. Then you can forget about the restoration of the latter.

Having got rid of the old disk, we clean the surface of dirt in the form of scale or dust. To do this, use a brush for metal or a nozzle for power tools. Later we clean the surface with special fluids. If you do not clean, the new part may sit on the surface with a large beating, which will lead to undesirable consequences.

Applying reverse hammer

We install the restored or new brake disk on an empty seat. Bolts for fastening need to tighten with a force of 20 Nm, in what the torque wrench will help. The caliper will require increased effort, which should be in the range of 100 ... 120 Nm. Do not over-tighten the fasteners so as not to get a radial runout of the hub. Assembly of the remaining elements of the node is carried out in the reverse order of disassembly. Be sure to monitor the position of the hoses so that they are in place.

Final operations

The assembled assembly must be checked for valid runout. For this purpose, the micrometer is mounted on the fixed part, and the disk is rotated. Each car model has a valid beat value. The indicator can usually be found in the vehicle manual.

For high-quality brake discs beating should not be more than 0.05 mm.

Having established into place a wheel, we lower a jack the lifted car. Several times press on the brake from the cabin. At this time, the pads are in contact with the disc. If necessary, pumping the brakes or setting the parking brake.