Car designers always strive to provide the driver with maximum visibility. To do this, reduced front struts are made around the windshield, rear-view mirrors are mounted, in which the “blind” zone almost goes away, and high-quality visibility is provided through the rear window.

To increase the transparency of the rear window helps filament heating built into the design. If for some reason heating does not work, what to do next we will tell in our article. Indeed, sometimes even on minor events noticed by the driver in time, safety on the road may depend.

Content

- 1 The working scheme of the heater

- 2 Total lack of heating

- 3 Partial working capacity of threads

- 4 Copper strip breaks on glass

- 5 Restoring the rear window heater

- 5.1 Using conductive glue

- 5.2 Alternative treatment options

- 5.3 Repair heater soft solder

- 6 Conclusion

The working scheme of the heater

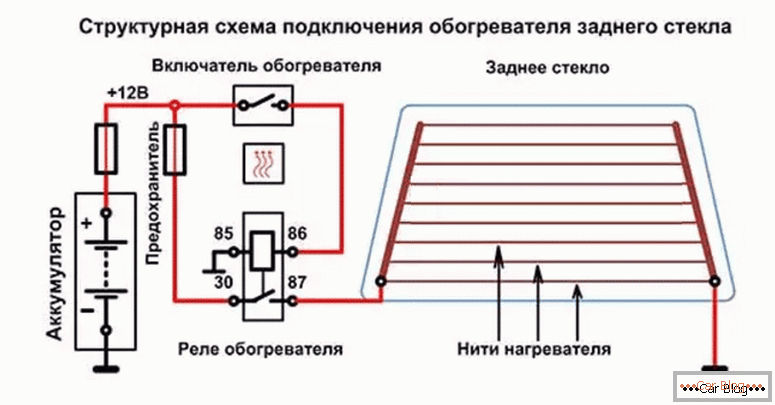

In order to properly repair the electrical wiring in this part of the car, you need to know how it works. In a typical embodiment, the positive wire is connected to the ignition system of the car through a fuse. The negative part is powered from the car body. One of the terminals of the heating grid is also powered by the car body.

Closing the contacts of the heating switch, voltage is supplied to the relay coil. This makes it possible to start the relay. Next, the voltage goes to the heating grid. In a parallel group of threads is heated due to the passage of voltage. Through the case the electrical circuit is closed at the negative terminal of the battery.

Total lack of heating

The efficiency of this element is calculated for a long period of operation of the machine. Therefore, repair of the rear window heating with their own hands or with the help of specialists is most often claimed when the car owner, for whatever reason, accidentally damages the heating filaments on his own.

You can often notice a fault even without additional equipment, since condensate is not removed at the point of contact breaking or the snow thaws for a long time.

You need to know that before repairing the rear window of a car, you need to turn on the “ignition” (key position “on”) for a few minutes, without heating it will not start.

There are models of cars, when you need to fully start the engine to start the glass heater. This algorithm saves the car owner from quickly discharging the battery, because in this case the battery can “sit down” in just a couple of hours.

The cause of the lack of current in the copper grid can be blown fuse. Replacing it in the unit with a guaranteed working, we will identify this fault. Also allowed is the option when the start of heating does not work after switching on due to the fault of the non-working button. Then none of the threads will warm up.

A signal to such faults can be the absence of light indication on the outer surface of the start button. Also, when the button is on, there is no heat with an inactive relay or problems of connecting contacts.

Partial thread performance

If the driver, who decided to check the rear window heating, is too slow, but the surface is thawing evenly, then the reason may not be in a hard frost. Perhaps the battery has a weak charge or the generator gives up little power.

However, most often the reason lies in bad connecting contacts. Oxidation could occur or a small mechanical break in the chain occurred. In this case, the voltage arrives, but with great resistance, which does not fully fully work out this node.

See also: Why the immobilizer does not see the key and what to do

Diagnosis is carried out with a voltmeter or multimeter. It is necessary to check the input voltage at the contacts of the heating grid and check the data with the voltage level on the battery. If the difference is more than 1 V, then a high probability is in weak contact.

Copper strip breaks on glass

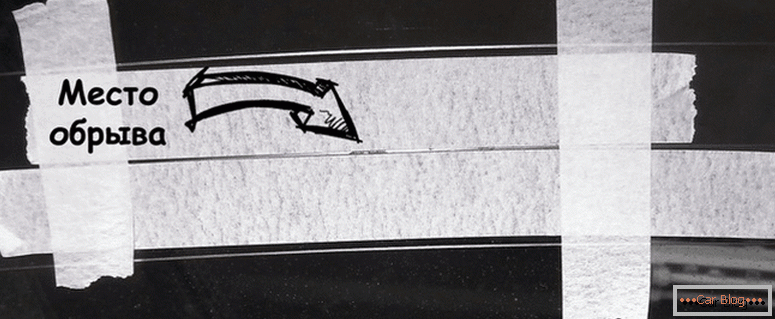

The most popular problem with heaters are the breaks of one or more threads. The horizontal cold strip with condensate will produce a problem level. Copper sprayed tracks are subject to rapid and easy rupture during mechanical impacts on the surface.

The problem is usually detected after transportation in cars of large or long cargo that can scratch glass with a hard end. Then, in the car, it is necessary to restore the rear window heating, since without it, visibility is significantly reduced during the cold season.

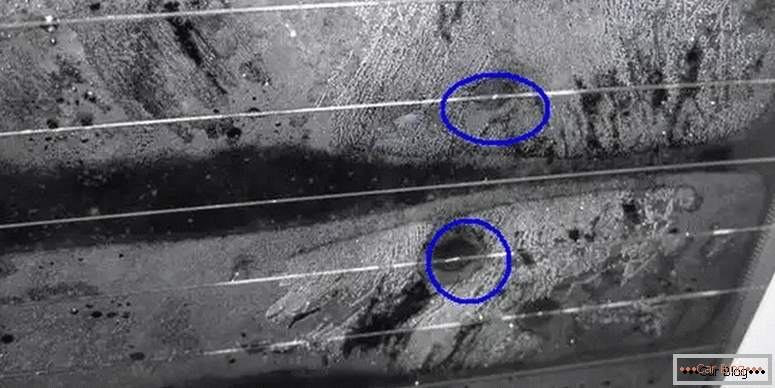

You can identify a problem track by bad warming up, but it is not always possible to determine the location of the gap without a special device. Also, several problem areas may have formed in the copper strip so that one of the devices will need to be detected:

- oometer;

- voltmeter;

- voltage indicator.

In the first two devices it is necessary to set up the display with a maximum voltage of 15 V. For the third one, it is enough to monitor the presence / absence of a light signal.

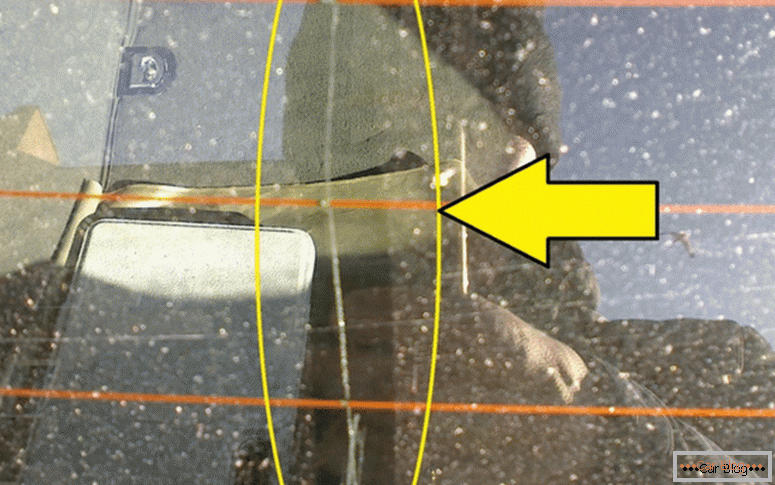

Before checking the operation of the heater, it is necessary to start the heating system. Now you need to check the voltage applied to the heater as a whole. For the operation, we put the indicator on the entry points of vertical tires located on both sides of the glass and interconnected by copper heating filaments. A properly working system should have a reading of 12 V. Deviation indicates problems with the supply of current to the heating point.

Next, measure the voltage on each thread. To do this, with one end touch the beginning of the track, and the second end of the tester touch its second side. There should also be readings at 12 V. If the device is fixed at 0 V, then the thread is torn. The point of break should be sought as follows:

- we fix one of the contacts at the beginning of the thread;

- we put the second contact on the opposite tire;

- the first remains motionless, and the second slowly we conduct horizontally along the thread;

- at the point where the voltage value appeared, you need to look for a break.

In this way, it is possible to detect breakages using an indicator light tester. Only instead of the appeared digital values the light signal will be noticeable.

You need to know that it is necessary to drive very carefully with metal objects, for example, a contact tester, on thin copper threads, so as not to damage the track surface.

Rear Window Heater Restoration

There are several ways to bring non-working heating threads back to life. For each car model, you can choose the most appropriate option.

Use conductive glue

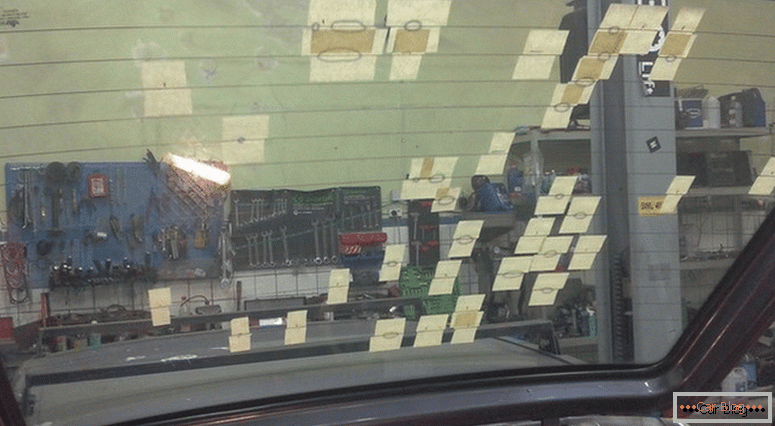

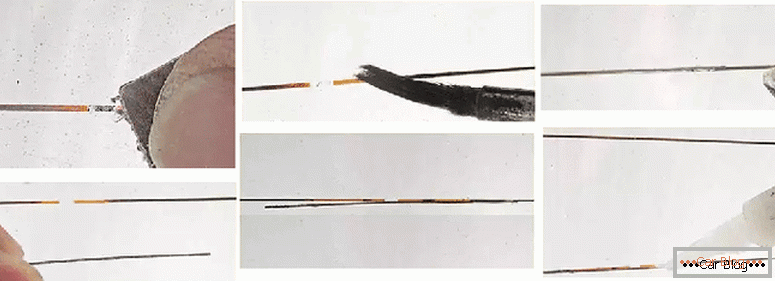

Having pulled out a gap, we will select the place of processing with the help of masking tape. To do this, glue the narrow strip over the thread, no farther than 1-2 mm. Repeat the operation under the thread. It is possible to limit the length of the treatment with the vertical adhesive strips.

See also: Diagram of the assembly unit VAZ-2110In the area of rupture with a syringe add a thin layer with conductive paste. After curing can be used. The drying process lasts 2-3 hours. At this time it is not necessary to include heating. The cost of repair will be about 10-15 dollars.

Also suitable for processing "Elecont". It is easier to buy than branded materials. Also isolate the place of treatment and apply the bottom layer. After waiting a little bit for drying, we fix a small piece of wire 0.3-0.4 mm in diameter at the site of the break. The ends must be tinned and protrude beyond the gap zone by 5-7 mm. Fix the wire with the second layer of conductive glue. The freeze also takes several hours.

Alternative processing options

Amateurs use a self-made mix of glue and brass sawdust mixed in equal proportions. However, the application of such material may not give the desired result. With the use of some flammable glue grades, such areas can ignite.

The method of using galvanic cooling of copper is also used, but the efficiency of such reproduction of the efficiency of the copper path in garage conditions is very low. The complexity of its high enough, and a successful result is not always guaranteed.

Repair heater soft solder

The reliability of such reanimation of copper tracks is confirmed by a large number of followers of this method. Financial costs are minimized, execution speed is high, and labor intensity is low.

To remove the insulating layer formed from oxidation in the zone of rupture, use a cloth moistened with acetone or alcohol.

You need to know that in no case can you clean the ends of the copper thread for soldering with emery paper, since a small layer of copper dusting will simply be mechanically wiped off the surface.

When the gap of the track is more than 7-10 mm, it is recommended to use inserts of copper wire 0.3-0.4 mm in diameter. Before starting work, this piece of wire must be tinned on both sides. On the track, tinning is not applied.

Effectively fix the cut will help the use of zinc chloride. They need to handle the ends between the gap track. We put copper wire on the plot and solder one end for a second with a twelve-volt soldering iron.

You need to know that if you shake a jumper soldered by one side, then it can easily fall off along with a new section of a copper thread, so you should handle it carefully.

The second side is also soldered for 1 s. The remaining flux and possible contamination are washed off with clean water. To save from mechanical damage, it is desirable to cover the treated area with heat-resistant glue, for example, “Moment” with cyanoarylate. It withstands heat up to 70S. This is quite enough for protection.

Conclusion

Properly repair the rear window can even do it yourself, without the involvement of specialists from the bus station. It is only necessary to stock up with high-quality and proven materials, which will be convenient for you to work with. Risk and apply dangerous repair options are not worth it, as possible damage may cost more than the saved resource.