Most drivers do not know firsthand what a manual transmission is. Very often you can hear the abbreviated name of the manual transmission or the common people - the mechanics. This box is a complex mechanism that converts mechanical energy into motion. Thanks to her, the car can change the speed and direction of its movement, as well as torques and force.

Types and types of mechanical box

There is a classification of manual transmission. Consider all the details. According to the method of gearing boxes can be divided into:

- gear cylindrical gears. They have such advantages as reliable operation, long service life. In turn, they can be chevron, oblique and straight-toothed. Spur teeth are easy to manufacture, but deliver a lot of noise when working. All this leads to rapid wear. Splined gears are particularly smooth when switching, low noise and high performance. Chevron gears are especially smooth at work;

- bevel gears. They intersect the axis of the input and output shaft, which allows you to change the direction of the kinetic energy;

- worm Possess low efficiency, but high gear ratio;

- wave. High abrasion resistant gear;

- chain;

- screw.

By friction, the manual gearbox is: belt and friction.

Purpose Manual

Manual transmission is designed to change the torque. It owes its name to the mechanical method of shifting gears. This box according to the classification refers to the step, as changes occur in steps. A step, in turn, denotes a pair of gears. Each such pair has its own gear ratio.

For the manual transmission is characterized by the following number of stages:

- 4-speed manual transmission

- 5-speed manual transmission

- 6-speed manual transmission

- above.

Widespread 5-speed gearbox, which is installed on almost all VAZs, even tuned VAZ 2109 is also mechanics. Each manual transmission has its own design. The most common two-and three-shaft gearbox. The latter is most often used in rear-wheel drive cars, and the first is on front-wheel drive boxes. Each of them has significant differences.

The device and the principle of the three-shaft manual transmission

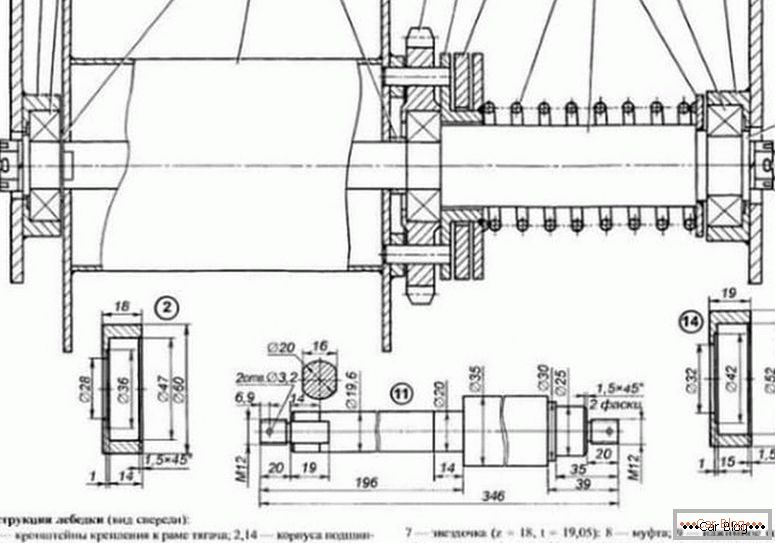

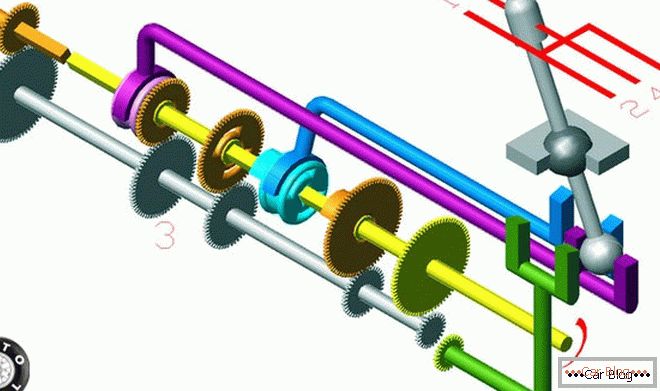

In its composition such a manual transmission has the following components. These are the drive shaft and its gear, the intermediate shaft and its gears, the shaft and its gears, the gearbox synchronizer, the mechanism for switching and the housing are driven.

This transmission works as follows. When the lever is in the neutral position, no torque is transmitted. As soon as the lever starts to move, the synchronizer coupling starts moving. Gearbox synchronizer allows you to synchronize the speed of the driven shaft and its gear. As soon as the desired value is reached, the clutch and gear teeth engage and freeze.

The transmission of torque to the engine begins, and then from it to the drive wheels of the car. In this case, the gear ratio is equal to the specified number. This box can also realize the reverse. This is achieved by using an intermediate shaft and its gear, the movement of which occurs in the opposite direction. This gear has a separate axis.

The device and the principle of the two-shaft manual transmission

This gearbox has the following design. It consists of such elements as the drive shaft and gear, the driven shaft and gear, the synchronizer coupling, the differential and the main gear, as well as the housing and the mechanism for implementing the shift.

Recommended article: The device of the car is not as complicated as it seems.

The principle of operation of a manual transmission is simple and in many respects similar to the work of a three-shaft gearbox. A distinctive feature is the work of the mechanism for the implementation of the gear shift. The lever with such a box can move up and down. When the lever starts to move across, the force goes to the cable. And he transmits the action to the cable of the choice of the desired transfer. There is a rotation around the axis and the choice of a given transfer.

If the lever then moves along, the force goes to the gear cable and then to the gear lever. This lever moves the rod horizontally, and the corresponding fork moves the desired synchronizer sleeve. The clutch, in turn, blocks the movement of gears. Thus, there is a transmission of torque through the engine to the driving wheels of the car.

Pros cars with manual transmission

A car equipped with manual transmission, has its advantages:

- there is an economical fuel consumption;

- the car picks up speed faster at the beginning of the movement;

- This gearbox will appeal to sports enthusiasts;

- allows braking on the transmission.

However, it should be borne in mind that mechanics are more difficult to control and require certain skills. When working smoothly with the clutch, the car will also go. Requires the greatest skills starting off. Here you need to skillfully use the clutch and gas. But the owners of serious tuned sixes are not soaring about this.

And here is a visual video of how the manual transmission works: