There are a number of reasons why the throttle valve is contaminated with all sorts of sediments. The main reason is the oily dust, which penetrates through the ventilation pipe of the crankcase gases from under the valve cover. Oil is deposited on all internal surfaces of the damper, thereby attracting motor dirt. It is impossible to prevent or stop the process of contamination of the throttle valve.

Absolutely in all engines crankcase gases are not immediately released into the environment, but penetrate first into the air system for a more environmentally friendly engines. Crankcase gases could easily pass through the throttle valve without causing damage to the engine, but oil mist is always paired with them. The entire dirty mass of gases is attracted by the oil, while it is deposited on the surfaces of the node, forming a dense coating that must be cleaned for normal operation of the throttle.

Signs of needing to clean the flap

As the deposits accumulate on the throttle, the engine will let you know that it is time to apply the necessary measures. These "symptoms" include:

- - uncertain start of the engine, often not on the first attempt;

- - revolutions at idle noticeably float;

- - The car starts to twitch at low speed (up to 15 km / h);

- - when shifting gears while driving, revolutions can fall rather slowly, and can too dramatically. It happens that the motor stalls at all;

- - a failure in turns around 1000 rpm.

Removing and cleaning the throttle

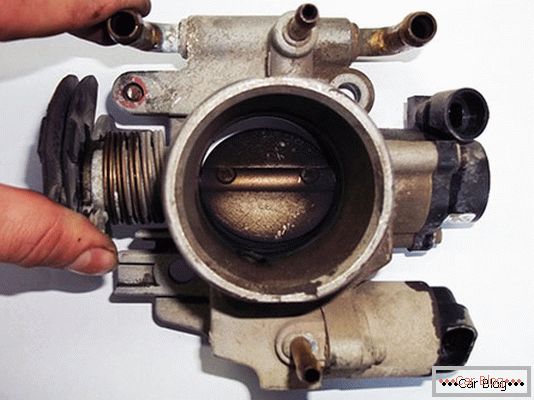

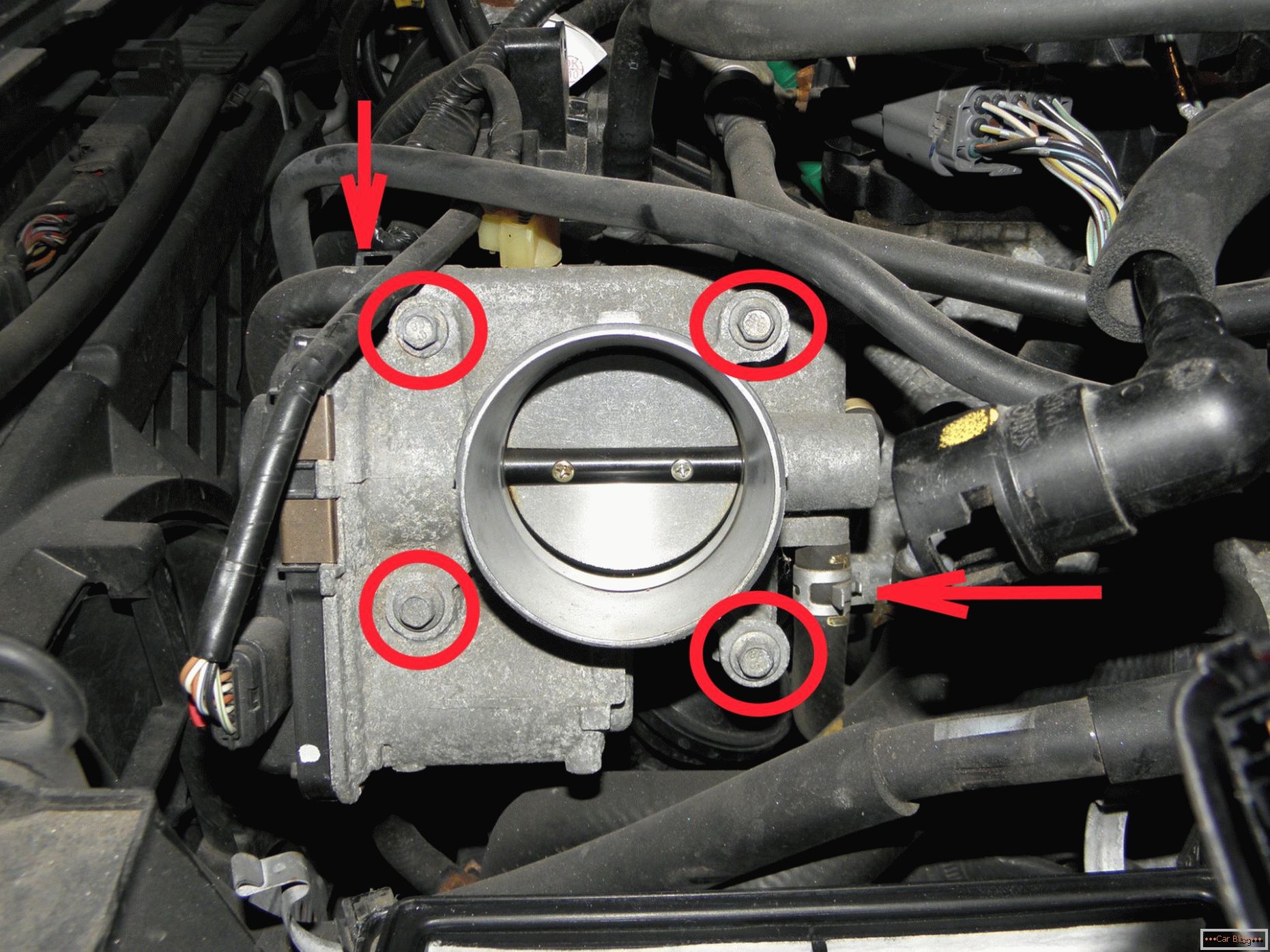

Cleaning the throttle valve is possible only after removing it. Before removal, it is necessary to disconnect the corrugation of the duct and disconnect the wire chip from the idle relay. The next point is to disconnect all hoses that fit the damper. To prevent anything from pouring out of them, you can plug them, for example, with old spark plugs. After that, remove the cable from the mechanical drive.

Read also: Hybrid motor on Toyota car - Is the purchase profitable?After disconnecting all the elements, you can begin its immediate removal. On different engines, it is mounted on two or four bolts, or studs with nuts. Then it is necessary to remove the flap position sensor and the idle speed regulator from the throttle assembly. After that, you can proceed to its immediate cleaning.

Flushing

The throttle valve is flushed with special cleaning agents for injectors or carburetors. The composition is quite aggressive, so you need to clean very carefully. Spray such an aerosol should be on all surfaces and in all channels. If the throttle has a fairly large layer of soot, spray these places and let stand for a couple of minutes. Thereby you will give an opportunity to the cleaning agent to a maximum of corrosive carbon.

Be prepared to achieve the desired result, you will need to carry out such an operation several times. Particular attention should be paid to the channel inside which the needle of the IAC moves (idle speed regulator), and the crankcase ventilation channel. In these places the greatest amount of sediment accumulates. The ventilation channel should be cleaned with a steel needle, after which, start cleaning with an aerosol. Regulator idling requires no less attention to clean it. Since the needle can “accumulate” so much on the surface that it will simply start to wedge.

Before reinstalling the throttle assembly, it is necessary to pay attention to the condition of the gasket. If it has minor damage, do not rush to look for a new one. It will be enough to walk on it with a small layer of sealant. Be careful that the sealant does not enter the throttle chamber. The installation of the valve is in the reverse order. After the entire assembly, it may be necessary (often very rarely) to adjust the throttle. Or rather, the tension of the cable, which could weaken over time.

See also: Oil pump and its malfunctionsIf clearing did not help

It happens that cleaning the throttle did not help. The engine still does not keep steady turns. This suggests that there are obvious hidden defects in the flap. The cause may be a malfunction of the throttle position sensor or the IAC.

Here are some symptoms that may suggest a sensor failure:

- - difficulty starting the engine;

- - increased fuel consumption;

- - loss of power during acceleration.

Repair sensor throttle useless, it is preferable to buy a new one. You can check the suitability of the sensor with a multimeter, or deliberately replace the old one - the working one. Signs indicating a malfunction of the idling regulator are as follows:

- - increased fuel consumption;

- - when you release the gas pedal at neutral speed, the speed drops very slowly, sometimes there may be a delay of 10 - 15 seconds, or the fall occurs too quickly, until the motor stops.

Of course, you can remove the valve again, and try to more thoroughly wash out the IAC, if this time did not help either, it means that the malfunction has become fatal and needs to be replaced.