After repairing the engine, all its systems must be restored to working condition. This also applies to the valve mechanism. With self-repair air tightness in the cylinders can be restored with the help of a roller cutter for valve seats. Also this tool is called countersink.

Content

- 1 Work the valve mechanism in the car

- 2 Choosing a tool for repair

- 3 Work

The work of the valve mechanism in the car

For each cylinder of the engine at least two valves are provided: intake and exhaust. Opening and closing them takes place in turn. When you open the intake - in the combustion chamber enters the fuel mixture. Then it closes, and the mixture burns. Exhaust fumes are removed when the exhaust valve is opened. Such cycles occur during the entire time the motor is running.

Valves work under adverse conditions. Aggressive environment almost constantly exposes them to various influences:

- mechanical;

- thermal;

- chemical;

- dynamic.

Manual chamfering

To ensure the most durable operation of the valve is made of high-alloyed durable steel. The composition of the alloy consists of chromium and nickel with a high percentage.

The valves consist of a guide rod and a working head, which has a flat or convex shape, and is also tulip-shaped. The tail part of the rod is made with a cylindrical or shaped groove that helps in fixing the spring.

Malfunctions in the operation of the mechanism are manifested in a decrease in the power output of the power plant. In addition, noticeable unstable operation of the engine at any speed. The most frequent breakdowns are:

- loose fit of the head to the body, after which a gap is formed that reduces the tightness of the system;

- the appearance of coke or soot blocking the complete closure of the valve, which also leads to depressurization.

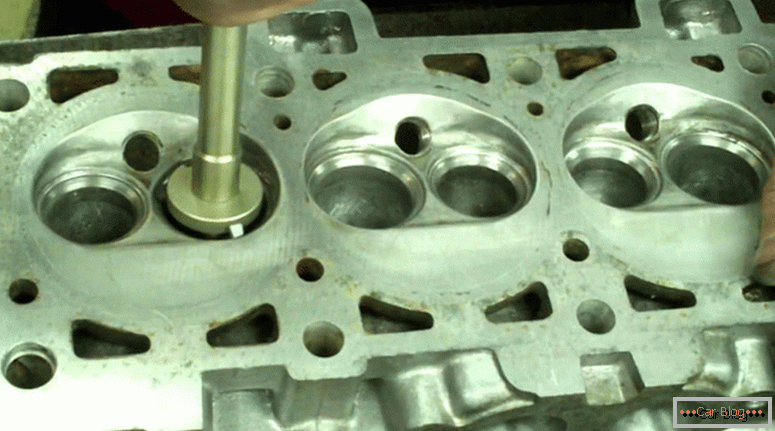

Body to be repaired

Signs of improper operation of the mechanism are smoke puffs from the exhaust pipe and an unnatural knock from the engine compartment with significant development on the rods.

Choosing a tool for repair

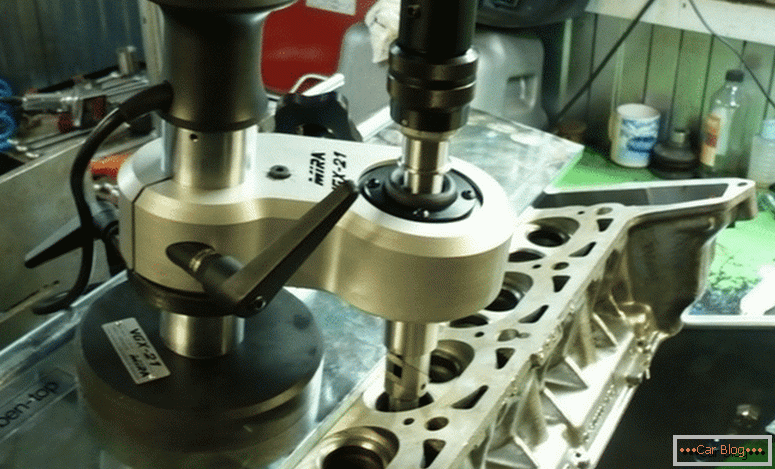

For repairs with a valve mechanism, a countersink or a roller cutter will be needed. These are the two names of the same device. Special kits for carrying out such operations are sold with structurally specified angles, but sometimes they require additional settings for a particular car. Before machining, you need to take measurements and verify the actual dimensions with the drawing ones.

See also: Evaluate the state of the engine by spark plugsThe cone is a steel cone with several carbide tipped cutters mounted on a conical surface. Along the axis of the cone is a hole for mounting the tool on the mandrel. It is necessary to pick up such countersinks on the working angle of the conical surface. It can be from 15 to 60 degrees.

Work

Put the cutting tool on the cylindrical mandrel. Next, we fix it and lower it with the axle into the hole for the valve stem. Thus, the working tool is centered with the axis of the holes.

Processing using the device

Rotate slowly, without strong pressure. Turn the tool clockwise, knives to the body of the body.

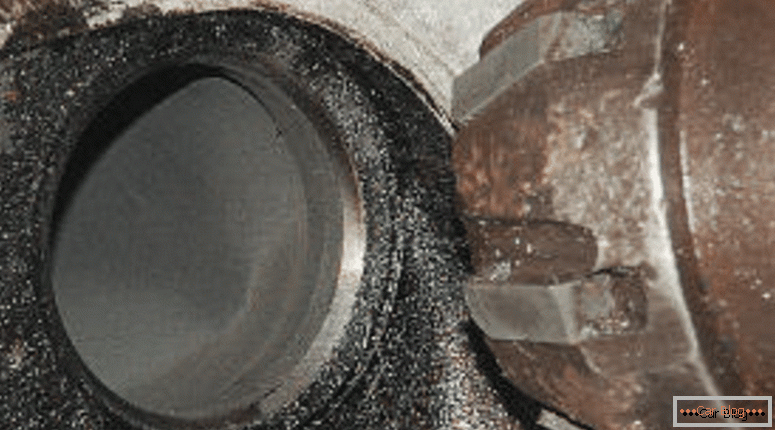

On the saddle engineers have provided three chamfers:

- top;

- working;

- bottom.

For each of them you need a separate tool with its own angle of inclination. The sequence of such operations can be selected independently, but it is desirable that the working chamfer should be last edited. So you can get rid of unnecessary burrs.

Formed chamfer should be at an angle that is specified in the technical documentation of the car. To identify the area of contact is grinding. It is necessary that the mating with the valve occurs over the entire surface of the chamfer, and not displaced in any direction along the axis. In this case, you will need to re-process the countersink.

When installing new valves, additional long lapping for mating is not required. If the valves are put old, it is necessary to abrade the surface of the seat and valve with an abrasive. The operation is performed manually within a few minutes. The result in the garage can be checked with a small amount of kerosene. It should not leak between ground surfaces when the system is closed.