The body of steel is today the most popular and sold body in the automotive industry.

Steel body

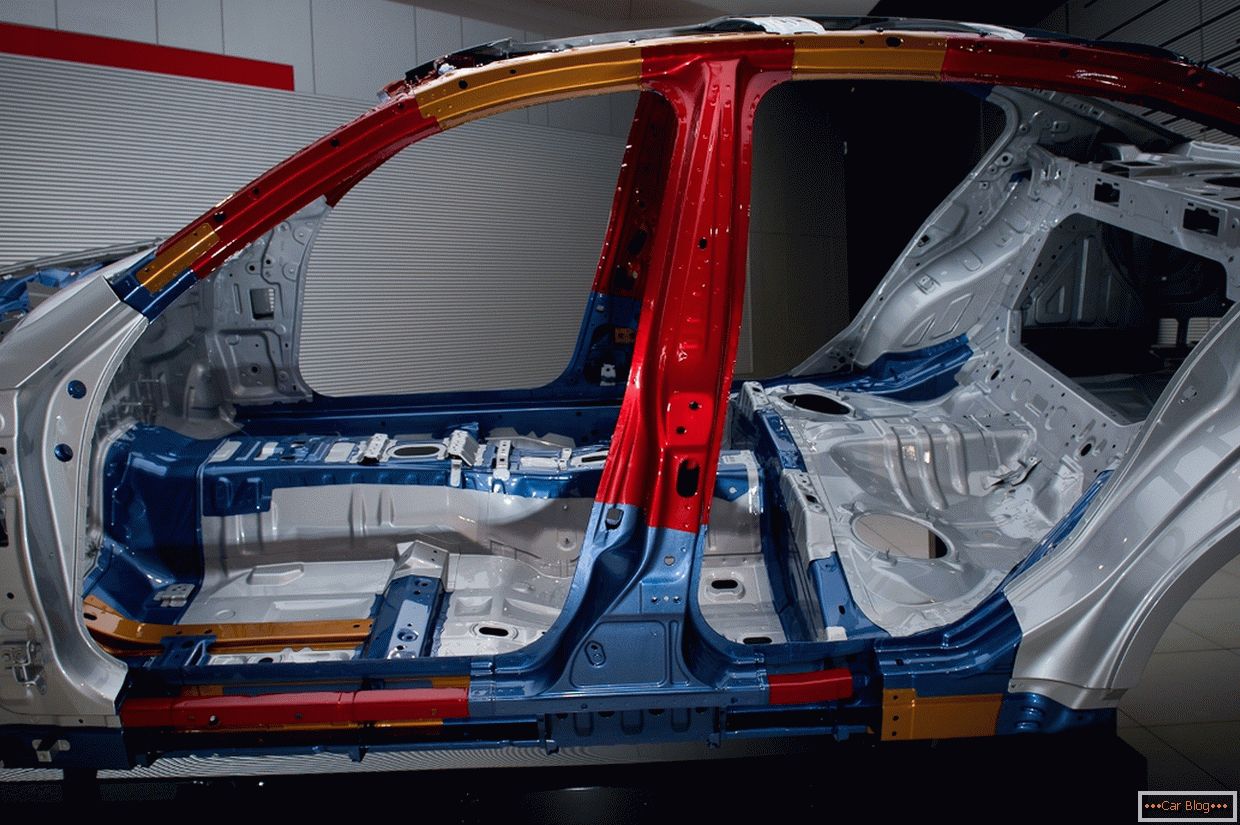

But the steel body can be of various alloys. For example, the body of sheet steel, has excellent plasticity. Such steel allows you to produce from yourself, most of the external parts, and like plastic, can apply various forms. High-strength steel has a hefty energy and excellent strength, so this type of steel is used in the production of power body parts. It remains profitable yet that in the entire history of the automotive industry, the auto industry managed to simplify and debug the skill of steel bodies, and this, in turn, makes them rather inexpensive.

With all its advantages, of course, there are also disadvantages. Steel is not lightweight, and like no other alloy is quite susceptible to corrosion. As much as possible to avoid the rusting process, methods of galvanizing steel body parts help.

Composite body

There is another version of the body - composite. This is the so-called "hybrid" composition derived from several compounds together. Optimal qualities of such a body are achieved by combining all the best qualities of different components. Composite materials, the most durable, of them can make the largest and most solid parts, which of course facilitates the production itself. Composite material includes, for example, carbon fiber, which is used in production most often.

For example, carcasses for supercars are made from carbon fiber. The disadvantages of this material can rightly be called - the complexity of its use in large-scale automotive industry. It is not uncommon to need manual labor, in turn, which will lead to higher prices for the car. Another drawback is the almost 100% inability to recover parts after deformation in accidents.

See also: The choice of studded and non-studded winter tires