One of the elements of the automobile clutch is the release bearing. Thanks to the work of the entire unit, the rotation is transmitted from the power plant to the drive shaft of the gearbox. From the quality of the clutch depends on the smooth switching between the steps of the box, a reliable connection of the engine and transmission. By pressing on the clutch pedal, the driver almost instantly disconnects the engine and gearbox.

Content

- 1 Need for release bearing

- 2 Proper testing of the bearing

- 3 Conclusion

Need for release bearing

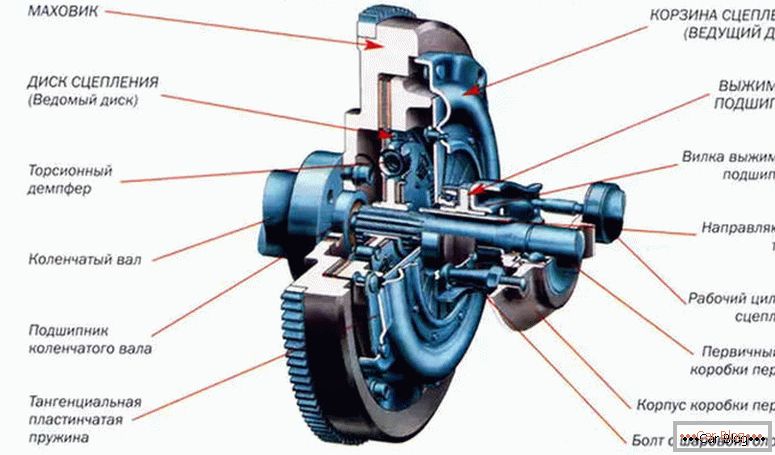

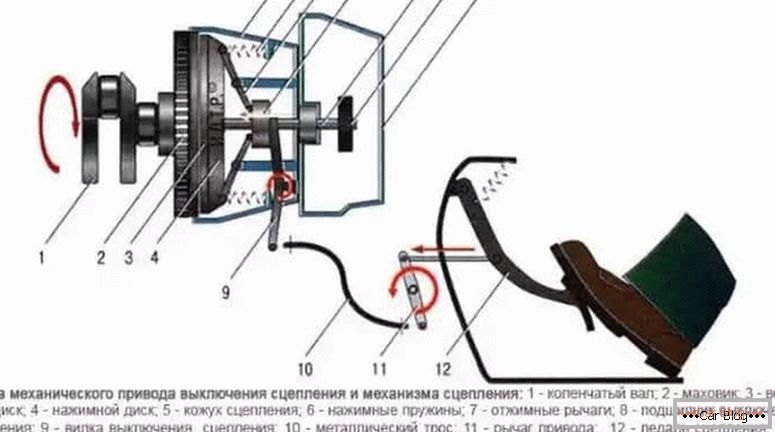

This part belongs to the most vulnerable of all components of the clutch basket. It is entrusted with the role of a working body for switching on / off the transmission of rotation. Engineers placed it in the center of the disk and rigidly tied to the pedal through the fork in the form of a rocker arm so that the entire load from pressing passes to it, transferring the force to the petals of the disks. Pushing the levers directly by the outer ring.

You need to know that by depressing the clutch pedal, the driver loads the release bearing. Frequent and prolonged retention of him in this position leads to the imminent failure of his.

The part is mounted on the guide of the drive shaft of the gearbox and freely moves there with the inner yoke along the axis. There are two types of construction:

- hydraulic;

- mechanical.

In the second case, classical roller or ball circuits of the device are used. The basis for such a detail is the mechanical interaction. When using hydraulics, the driver does not have to make great efforts while pressing.

There is no consensus about the optimal and universal design. Each clutch release bearing shows signs of malfunction in its own way, according to its design. Most cars equipped with a hydraulic unit. The domestic auto industry favors mechanics for its low cost and practicality.

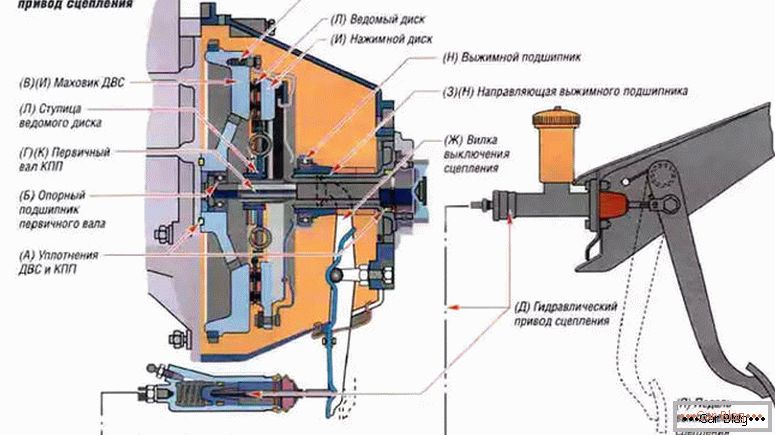

The hydraulic system performs the same functionality, but has a more complex device. For proper operation of this type, high pressure hydraulic fluid is used.

See also: How many liters of oil in the gearbox, and where it is pouredAt the heart of the design is a cylinder, several pistons, piston stops, hydraulic wiring, seals, anthers. While the motorist is pressing the pedal, the liquid goes under the piston face. Due to the high pressure there is a movement of the piston, which presses on the levers of inclusion, separating the driven and driving disc. When the driver releases the pedal, the fluid moves in the opposite direction and all hydraulic parts return to the primary position.

Чтобы понять, What is clutch release bearing, и из каких составных частей он собран, можно рассмотреть представленную схему.

Breakage of a mechanical or hydraulic unit makes it impossible to continue using the vehicle until the breakage is eliminated or the unit is completely replaced.

Proper testing of the bearing

In most car models, manufacturers install release bearings with a high degree of reliability. Due to this, during operation, their life is distributed over a large mileage, because it enters the work only if the clutch pedal is depressed.

A part is subjected to significant loads during a sharp start, the drive wheels slip, long journeys, for example, on a highway with poor quality coating.

Bearing breakage

The driver must notice the problem with the release bearing in time to carry out preventive work with the clutch. Specially provided diagnostic tools to identify its performance is not provided. It is possible to determine the damage by indirect signs that have differences for mechanical and hydraulic structures.

The obvious symptoms include these phenomena:

- during operation of the gearbox, noises are heard;

- unable to switch speeds freely;

- traction пробуксовывает.

First of all, the clearance of the fork and the stem of the working cylinder is controlled. Then we find out the condition and performance of the release bearing. We need to start the engine, squeeze the clutch, and then analyze the noise. Obvious knocks or whistles that appear during pressing and disappear after the pedal returns to the upper position indicate a bearing failure.

Identify the physical condition of the parts can be after dismantling the box. You will need to remove it simultaneously with the input shaft guide and the coupling.

During visual diagnostics, we determine the allowable backlash, jamming, damage to the body. A problem may occur after the production of a lubricant. In this case, we remove the contamination and fill the assembly with Litol or another suitable lubricant, and then return everything to its place. Need to check the smoothness and quality of rotation. After complete assembly, we check the performance on the engine.

See also: Which transmission is better: automatic or mechanic

Often found on the hydraulic design of such an indirect sign, as the failure of the pedal. This is due to the lack of tightness of the actuator and the piston on the bearing. Before dismantling the box, the driver must check the status of the working and main cylinders of the drive, and also monitor the entire hydraulic layout of the unit. You will need to look into the tank to control the level of liquid, as well as to ensure that there are no air traffic jams.

Conclusion

Motorists in the diagnosis of such problems with the clutch in most cases guided by hearing, vision and intuition. If you have doubts or lack of experience, you should consult with experts at the station.

With independent inspection of the bearing, it is desirable to use a 10 ... 20-fold magnifying glass to detect small cracks. If there are visible traces of overheating, wear, mechanical damage in the form of chips or grooves, the part must be replaced.

Independent work with a checkpoint must be carried out on a flyover or a lift. The car should be as securely fixed as possible, not allowing kickbacks. To perform such operations in the garage will need outside help.