Modern cars are a complex set of various parts and mechanisms; therefore, it is problematic to maintain the proper state of the components. But worst of all, when at the critical moment the car suddenly fails.

Therefore, before the next departure, it is necessary to conduct a thorough technical inspection of important systems. The most familiar is to check the condition and level of engine oil, tire pressure, coolant level. Also do not forget to check the alternator belt, namely the degree of tension.

The generator should work properly and produce the required voltage for the normal functioning of the car’s electrical systems. Performance depends on the speed of rotation of the pulley, so the serviceability of a belt drive is very important. The mere presence of a belt will not be enough for the normal operation of the generator, it must have a certain level of tension. Only in this case you can really not worry about the power supply of the car.

Content

- 1 Importance of setting

- 2 How to tension the alternator belt

- 3 How to tighten the alternator belt using the adjusting bolt

The importance of setting

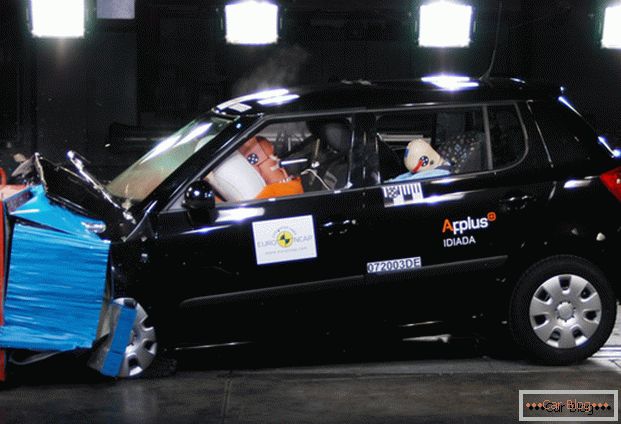

To check the tension of the alternator belt, you need to press on it with your finger

The belt transmits rotational motion from the crankshaft to the generator. It is made from very durable elastic reinforced rubber. It connects two (or more) pulleys, the rotation speed of which is several thousand revolutions per minute. In such conditions, it is important that the belt is as close as possible to the corresponding groove of the pulley. This will prevent possible slippage. The weak tension of the alternator belt is often accompanied by a characteristic whistle from the engine compartment. Belt tension can be:

- insufficient;

- excessive;

- optimal.

When the belt is weakly tensioned, it can slip, and this reduces the efficiency of the generator. Also, slippage of the belt causes its premature wear. Strongly tensioned belt contributes to the failure of the generator bearings.

The correctness of the tension adjustment can be checked by pushing the middle of the belt between the two pulleys.

See also: How to revive a car batteryHow to tension the alternator belt

The generator is mounted on the engine in such a way that it can rotate in a certain range relative to the axis of the mounting bolt. The position of the generator is fixed by an arcuate bar with a special slot and nut. The optimal tension of the alternator belt is performed while observing the following sequence of actions:

- First you need to unscrew the nut, which is on the bar.

- Using a mounting spatula or other suitable tool, press the generator.

- Then tighten the nut back on the bar.

- Now you can check the belt tension and if you need to repeat the whole process.

How to tighten the alternator belt using the adjusting bolt

The easiest way to consider the tension of the belt with the adjusting bolt

The most progressive, convenient and practical method is bolt tension leveling. To perform this procedure qualitatively, you must adhere to the following algorithm:

- Tighten the nuts of the lower and upper levels of the generator mounting is required to loosen.

- The adjusting bolt rotates strictly clockwise. Then you need to take the generator from the main unit, while controlling the degree of tension of the belt mechanism.

- At the end of the nut mounting the generator must be properly tightened.

Regardless of the chosen adjustment system, after performing the whole procedure, using a special key, 2-3 turns of the shaft should be carried out, and then again check the tension. Also, the measurement will need to be carried out after a short trip.