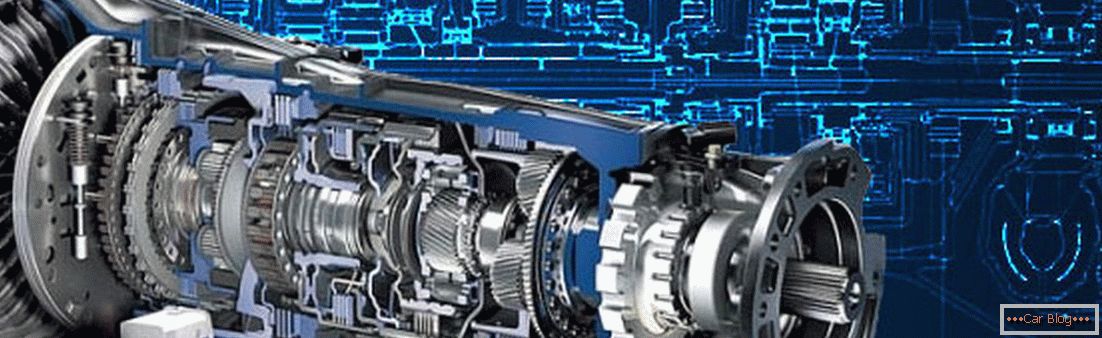

The basic elements in any automatic transmission are always the same:

The role of the clutch performs the torque converter. Rotational motion on the wheels is transmitted through it. The main task of the torque converter to ensure the rotation of the wheels of the car without jolts and pauses.

Hydrotransformer consists of large wheels with blades that are completely immersed in the hydrotransformer oil. Due to the oil flow and pressure, the rotational movement is transmitted to the wheels of the car. For high-quality and smooth change of torque, meets the reactor, which is located in the torque converter.

cross section transformer

Planetary gear, which contains a set of speeds. It is alternately locking and unlocking gears, determining the desired choice of gear ratio.

The set of brakes and clutches is responsible for the successful smooth transition between gears and gear shifting.

The control unit (hydraulic unit) - controls the automatic transmission. It consists of an electronic unit in which the automatic transmission control process takes place, taking into account all sensors that collect all information about the correct operation of the box (speed, mode selection).

The principle of the automatic transmission

When the engine is started, oil is supplied to the torque converter, and the pressure increases many times over. The pumping wheel begins to move, while the turbine and the reactor are stationary. When you turn on the speed and supply of the fuel mixture to the combustion chambers, the pump wheel starts to rotate much faster. At the same time, the oil flows start spinning the turbine wheel.

The torque of the turbine wheel begins to transmit torque to the wheels. When the desired speed is reached, the turbine and pumping wheels begin to rotate at the same speed, the flow of oil enters the reactor from the other side (the movement begins to go only in one direction), as a result of which the reactor starts to rotate. The system goes into hydraulic clutch mode.

If the resistance to the wheels increases (moving uphill), the reactor stops rotating and begins to enrich the pumping wheel with torque. Shift occurs when a certain speed is reached. The electronic control unit gives the command, after which the friction clutches and the brake band begin to brake the downshift, and the hung gear starts to be accelerated through the valve with the help of the created pressure in the oil, thereby switching gears without losing power.

See also: Three main reasons for the automatic switching of the box in emergency modeWhen reducing the speed or stopping the car, the pressure in the system decreases, resulting in a reverse gear shift. On a non-working engine, the torque converter is not under pressure, so starting the car with a “pusher” will not work.

Conventional modes of automatic transmission

- Р - parking, when the car is on a flat horizontal surface, the parking brake is optional.

- N is neutral. At neutral speed you can tow a car.

- L - (D2, D3) - movement on low gears (2nd gear or 3rd gear).

- D - city - highway mode, switching from first to last transmission.

- R - reverse.

- S - sport mode. Engine performance at maximum speed.

In addition, on some automatic transmissions there is an Overdrive button that prohibits shifting to a higher gear when overtaking. Button Snow - involves moving off on a slippery surface with 2 or 3 gears, while bypassing the process of slipping. ShiftLock (button or key) - unlocking the selector when the engine fails or the battery is seated, for further transportation of the vehicle.

Features of a car with automatic transmission

Everyone knows of course that the automatic gearbox is much more complicated in its structure, unlike the manual transmission. Therefore, the repair of such a box is much more complicated and requires large investments. As a rule, even an experienced driver can easily see the initial stage of automatic transmission malfunction. This will be indicated by “kicks” and pauses when changing gears. One of the speeds or even reverse, may generally disappear. In more serious cases, cars simply will not budge.

See also: The reasons for the inclusion of emergency mode automatic transmissionAuto Diagnosis

It will be quite difficult to figure out what the problem is with your own strength. In the initial period, you can see the oil level, and visually determine what condition it is in. If the oil has a rather dark and sometimes black color or contains metal chips or fragments in its composition, this indicates internal damage to parts or wear on the automatic transmission. Initially, you can change the oil in the box, it will certainly solve most problems.

Of course, this problem will be solved much faster and more professionally at the service station Diagnoses can reveal a number of problems. Electronic gearbox control elements (computer, sensors) could fail, after which the automatic transmission will not function normally. Removal and installation of automatic transmission is one of the most difficult jobs in car repairs. Cost, removal, repair and installation of automatic transmission, can be compared with the purchase of a contractual transmission.

Automatic operation

First, you should always monitor the level and color of oil in the gearbox. Timely change it as required by the characteristics of the automatic transmission. Be sure to fill exactly the oil, which the manufacturer claims. For example, in Honda's cars, only its own oil is applicable; if you pour something else, the box is likely to fail.

In the cold season, starting the engine, be sure to let the box be enriched with thickened oil. To do this, warm up the engine, turn on the gear and stand on the brake for at least a minute, then you can get under way. Do not allow the machine to slip or constant sudden braking. In modern cars, automatic boxes are pretty reliable. Following these small rules, the automatic transmission will serve you for a very long time.