Modern internal combustion engines are necessarily equipped with cooling systems. The most progressive is the fluid type. This is due to the fact that in the engine block the temperature can reach 1800-2000C. At the same time, only part of the heat is transferred to useful work, and the remaining unclaimed thermal energy must be removed to the atmosphere.

To ensure the correct heat removal and performance of individual components of the system, it is necessary to know the structure of the engine cooling radiator and other elements included in this process. If you do not support them in working position, then this can quickly affect the failure of the power plant, and also entail costly repair of the motor.

Content

- 1 system operation

- 2 Variety of designs

- 3 Current system

- 4 Design and function of the engine cooling system radiator

- 5 The presence of a thermostat

- 6 Security Measures

System operation

A significant increase in temperature in the cylinders of the motor can lead to geometric deformation of parts, burnout of lubricants and distortion of technological gaps established by the manufacturer. As a result, such events contribute to a significant increase in wear of the mating products. Increased risk of sticking or sticking.

It is important to know that an overheated engine contributes to a reduction in the filling ratio of the cylinders of all types of power plants, and for gasoline engines the negative effect is in the form of a decrease in detonation combustion of the air-fuel mixture.

Supercooling of the power plant is also undesirable. Too cold an internal combustion engine loses its power quality due to heat loss, because the following processes occur:

- grease becomes too viscous;

- increased friction;

- a certain amount of fuel is condensed, removing part of the lubricant from the side internal surfaces;

- due to sulfur compounds appear pockets of corrosion.

The principle of operation of the engine cooling radiator is to maintain the most advantageous thermal mode for installation. It is important to understand.

Variety of designs

In vehicles with internal combustion engines there are such types of cooling as:

- air;

- liquid based;

- combined.

The first type is considered obsolete. It was used on the old "Zaporozhtsy", the noise from which was heard for many kilometers. The cylinder block was made ribbed (increased recoil area), and the air flow from the fan was directed to it.

Liquid systems are used on all modern engines. Special solutions are used as circulating liquids, for example, antifreeze with a low freezing point.

In combined wiring systems, the installed fan is supplemented. It starts automatically.

Liquid systems are open when the circulation provides access to the external environment through the use of a vapor tube. A closed circuit does not involve communication with the environment, which allows the pressure to be kept above atmospheric pressure inside. The second type by increasing the pressure increases the temperature of boiling. As a result, the liquid can reach 110-120WITH.

There are three most popular options for moving a coolant:

- Forced. The design involves a pump that forcibly drives antifreeze through pipes.

- Thermosyphon The movement of coolant is carried out due to the difference in the density of antifreeze, located inside the radiator and the one that is in the channels of the shirt. In the process of work, the warm mass from the motor goes to the upper area, moving to the radiator tank. Everything cools down there, its density coefficient increases, which allows it to move down to the inlet nozzles of the engine jacket.

- Mixed (combined). In more overheated elements, for example, the cylinder head reduces the temperature by force using a pump, and the shirt of the motor works in thermosyphon mode.

Current system

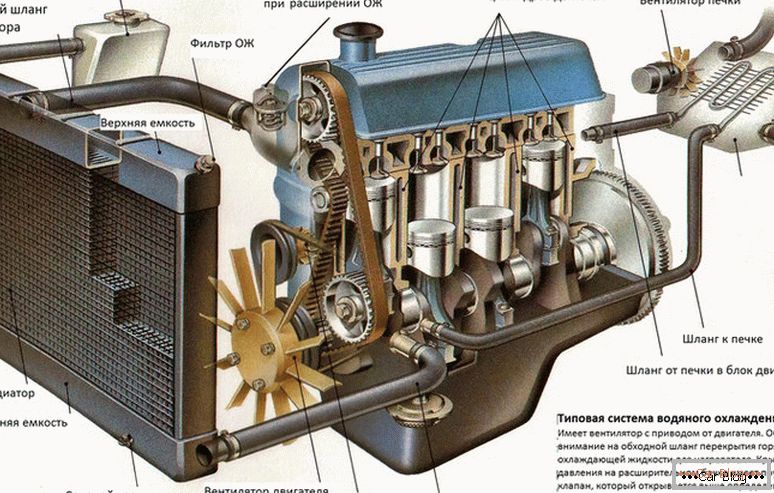

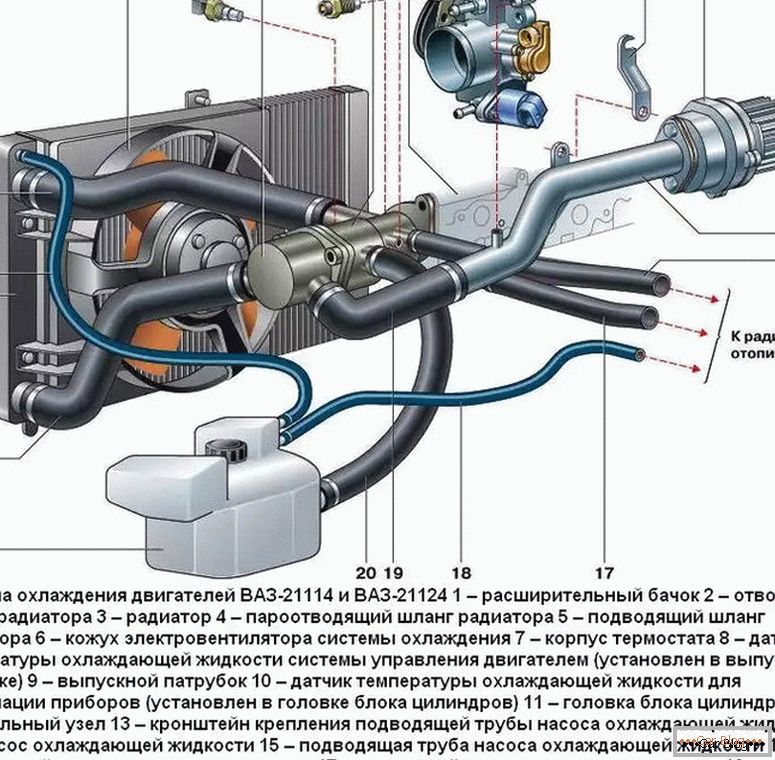

The overwhelming majority of domestic and foreign cooling systems seem to be closed, where liquids are forced to move. Their main elements are:

- cooling radiator;

- branch pipes and connecting hoses;

- shirt (technological channels of the block);

- water pump;

- multi-fan;

- thermostat.

During operation of the power plant, the antifreeze in the channels of the jacket receives heat from the engine. Then it moves along the available channels to the radiator to cool down, and returns back through the other channels. A pump located in the system helps the movement, and a large fan behind the radiator contributes to cooling. The intensity of work is corrected by the built-in thermostat and timely autostart / auto-stop of the fan.

Topping up the required amount of antifreeze through a special neck in the radiator. This can also be done through the expansion tank. As a rule, about 6–12 liters of antifreeze fit in modern systems. It will be possible to replace it after a complete drain, unscrewing the cover on the unit or at the bottom of the radiator tank..

Design and function of the engine cooling system radiator

Excessive radiator heat is removed to the surrounding space. This is facilitated by its special design. The main elements of the product are:

- top tank;

- lower tank;

- core;

- fasteners.

The most popular materials for the manufacture of radiators are:

- copper;

- aluminum;

- copper alloys;

- alloys based on aluminum.

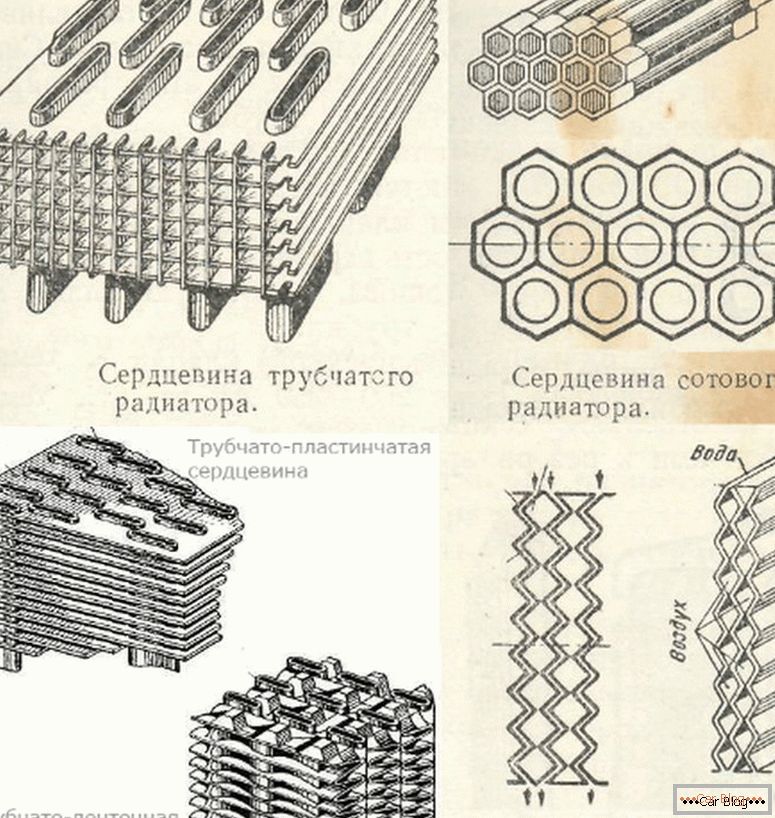

The core of the product is made in different forms. There is a tubular type, it is a plate variant, and also comes in a cellular form. Most often you can find a tubular structure. Inside are vertical tubes with a cross section in the form of an oval or circle. They are passed through rows of thin plates mounted horizontally. They are soldered to both tanks.

It is important to know! The presence of plates not only contributes to increasing the rigidity of the structure, but also has a significant positive effect on heat transfer.

Oval tubes are preferred. They have increased cooling surface, and this contributes to rapid heat transfer. Also, if undesirable liquid freezing occurs, the oval is only deformed, and the circle is able to break, depressurizing the system.

Lamellar variants of execution meet less often. In them, the coolant moves along the volume, which is formed by two figure plates soldered to each other. The lower end part and the upper part are connected to the tanks. The cooling air moves along the outer part of the plates. To increase the cooling surface, the plates are made of corrugated. Thus, it is possible to quickly cool down than with tubular counterparts.

However, there are more disadvantages with plates. They are manifested in rapid pollution, the need for a larger number of welded areas, the use of more thorough care.

Honeycomb core structures suggest the presence of horizontal round tubes for air, which are washed outside by antifreeze. To ensure a comfortable soldering of such systems, the tubes are flared at the ends to a hexagonal shape. This format provides a larger than analogous cooling surface.

The upper part of the barrel, located above, is equipped with a soldered neck. Outside, it is closed with a special stopper with a steam valve. Also to the tank fits a small pipe that needs to be connected with a flexible hose. Through it coolant is supplied.

In the lower tank there is a discharge pipe with a flexible hose. For high-quality fixation used screw clamps. This design allows you to have a small offset of the unit relative to the cooler.

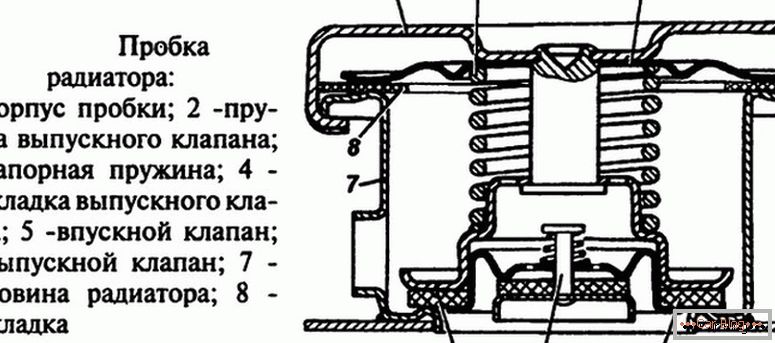

See also: Can I mix red and green antifreezeCork helps to isolate the system from the external environment. Its design contains the following elements:

- metal case;

- steam valve;

- air valve;

- blocking spring.

With a possible boiling of the cooling system increases the level of pressure inside all tanks. Upon reaching a certain critical value, which is set by the manufacturer, the steam valve opens, and the excess pressure is released into the atmosphere. This is a normal event.

Otherwise, the air valve is activated. After the vehicle stops, the liquid is cooled, during which the steam condenses and the pressure in the system drops below atmospheric. The inlet valve from the radiator cap helps to avoid squeezing the tubes inwards. After opening, it lets in some air inwards, providing a balance of internal and external pressure.

The expansion tank helps to compensate for the required working volume of antifreeze. It should keep the liquid in the amount set by the manufacturer. It is important to monitor the level of fluid in the expansion tank.

In certain models of radiators there is no filler nozzle. Add antifreeze to the required volume then through the expansion tank. The control of occupancy is carried out only on a cold motor.

The presence of a thermostat

An important role in the system is also assigned to the thermostat. It helps to quickly pick up the desired temperature of the engine and maintain it during the operation of the power plant.

Most often, they are mounted in a cylinder head cooling jacket along the path of fluid circulation from the unit to the upper radiator tank. The following types of thermostats are used, which differ in the type of filler:

- with solid filler;

- with liquid filler.

In the first situation, a small small capacity tank is embedded inside the element, the inside of which is filled with filler is a mass of ceresin and copper powder. The upper part is sealed with a lid and separated from the container by a special diaphragm. In the upper part there is a rod, affecting the built-in valve.

To an elevated temperature, the contents of the tank are in solid form, and the valve is closed. During the heating of the motor, the contents of the cavity melt, with an increase in volume, acting on the special diaphragm, rod and opens the valve.

In the second situation, the thermostat kit includes the original form of a brass cylinder, body, stem and double valve. Inside the cavity there is a volume of liquid that boils at 72-74WITH. На холодном движке клапан закрыт, и тосол двигается по меньшему кругу. При нагреве обеспечивается расширение, и открытие клапана.

Security measures

The driver must monitor the temperature from his seat. For this, he has a special scale with an arrow that should be in the middle position. Also, when the threshold value is exceeded, the corresponding indicator light on the instrument panel lights up.

Movement with a significant excess of the set temperature is not allowed. We need to stop and wait for the cooling fluid. It is forbidden to open the lid on the radiator when the engine is hot, so as not to get burned by steam. Topping up is necessary to carry out only after complete cooling of the motor.

Without the required amount of antifreeze, you cannot continue driving. It is necessary to call a tow truck or tow a car to a service station so as not to jam the engine. We recommend to carry with you a container with several liters of antifreeze, the quality of which corresponds to the season of the year.