In modern cars, manufacturers install a large number of all kinds of electronic equipment. Special attention is paid to sensors. Information from them flows into the head unit (electronic control unit), where data is analyzed, and then commands are sent to the actuators.

One of the most popular sensors is DFID, what it is, we will describe further. On how it functions correctly, depends on the performance of the vehicle. It is important to timely diagnose it with the help of available tools.

Content

- 1 What is DFID responsible for?

- 2 Location

- 3 How it works

- 4 Health Monitoring

What is DFID responsible for?

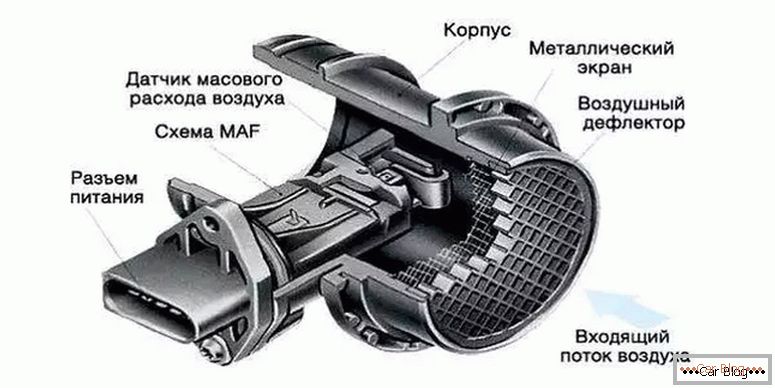

This abbreviation stands for mass air flow sensor. In foreign literature, one can often find its English-language analogue Mass Air Flow Sensor or the abbreviation MAF.

What is DFID in a car? The main functionality of this device is to control the amount of clean air sent to the working area of the engine. This mass penetrates into the cylinders to form a fuel-air mixture. The quality of the working mass (it will be depleted or enriched) depends on how much oxygen enters the engine.

Finding out what the DFID influences, it is worth considering that adjusting the amount of air penetrating into the engine will be able to influence the load on the power plant. The engine will work lighter or harder.

It is necessary to know that problems with the air flow sensor will soon lead to the preparation of a mixture with an incorrect proportional ratio, and this extremely negatively affects the operation of the engine.

Location

To monitor the status of the device, you need to know its place of installation under the hood. Therefore, motorists are often interested in where the mass air flow sensor is located. Manufacturers of cars often put it behind the air filter in the corresponding pipe.

This arrangement allows you to work with clean air without inclusions of dust or other solid contaminating elements. Otherwise, such particles will destroy the device. To create a smooth operation, you need to timely change the dirty filter in the car.

See also: What is the ECU in the car, where isIt should be borne in mind that in certain models of vehicles, the sensor mounting elements have a symmetrical arrangement. The device in such a situation can be fixed in a randomly erroneous way. To prevent this from happening, manufacturers put a special arrow in the form of an arrow on the outside of the case. It indicates the correct direction of air movement.

How does it work

It must be borne in mind that many years have passed since the invention of the first air flow sensors. They were improved and modernized by manufacturers. In this regard, how DFID works depends on its release time.

- Scapular type. Such devices did not lose their relevance until the 80s of the last century. Visually, they are similar to the throttle. A variable resistor shaft was equipped with one or more blades. Moving along the nozzle air flow provided them with rotation. The resistor was under voltage reference. Information about the voltage change came to the head unit. Meet such a complete set can, for example, on the old "three" BMW. The operation of this node was not always absolutely stable, which often led to failures.

- A more technologically advanced control option is air pressure monitoring. According to the classical laws of physics, it is known that during an increase in the rate of gas flow through a pipe, the pressure value drops. Individual manufacturers installed an air flow sensor based on volumetric consumption. The disadvantage of the models was an incorrect value of the oxygen level in the gas-air mixture. This is due to the fact that with increasing temperature the density of the gas decreases, which ensures a decrease in the amount of oxygen in the volume. Based on this practice, a special device, an intercooler, is installed in certain diesel cars. It is necessary to reduce the temperature of the incoming air, which leads to oxygen enrichment and increased power characteristics.

- Anemometric type. These designs are typical for cars produced since the 90s. The theoretical general scheme implied the presence of two devices in the complete set: a thread for heating from refractory materials and a temperature sensor. This type of air flow sensor worked quite simply. The ECU sent a small current to the filament, which led to its heating to a fixed temperature. The set value was controlled by the sensor. When the car was moving and the driver pressed the gas pedal, there was an increase in the speed of air movement in the working port. Thus the cooling of the filament occurred. Electronics increased the current given on a thread, for maintenance of temperature. One option for modifying the design is to use a plate instead of a thread.

- The novelties are WWWR with platinum plates. Based on the cost of this device, the presence of precious metals there can be believed. Platinum-plated silicon bases can be used. So far they have not had time to gain wide popularity.

The principle of operation of modern devices implies a self-cleaning technique. This process occurs when starting the calcination mode of refractory elements. High-temperature heating is provided (sometimes up to 1000WITH). During this time, dirt and oily growths are removed from the surface.

Health monitoring

The car owner can independently by indirect signs monitor the operation of the sensor. When identifying problem symptoms need to take action. Hazardous characteristics include:

- lack of stable operation of the power plant;

- the presence of power failures while holding the gas pedal;

- the engine starts unstable, which often manifests itself in cars with a diesel engine;

- if the engine speed is floating, then this is also a characteristic symptom.

It must be borne in mind that some brands of cars may not start at all if the air flow sensor breaks. If the problem happened on the way, then we recommend to temporarily fold it away from the connector, breaking the circuit with the computer.