The motor installed under the hood is considered to be the heart of any car. On the quality of his work depends largely on how the car will be operated. One of the main tasks is to maintain stable speed in different modes. If there is an imbalance of systems, then it is necessary to ensure synchronism of work.

Often, problems arise with the internal combustion engine not only while driving, but immediately after starting the ignition system. Turns begin to swim. Will require competent diagnosis. Прежде всего стоит определить, why swim idling speed, ведь причина может скрываться как в износе отдельных элементов, так и в банальном загрязнении.

Content

- 1 What is the mode XX

- 2 Popular causes of engine instability

- 3 Bringing the internal combustion engine to stable operation

What is the mode XX

When starting the engine starts idling. In this case, the car is standing still, a neutral gear is engaged at the gearbox, and the engine is operating with a minimum load, spending a small amount of fuel. This type of work is in demand in the following cases:

- ensuring the operation of the engine at neutral speed, when the car is not required to turn off due to a broken starter or dead battery;

- in the implementation of the warm-up of the motor in the winter;

- lubrication of the main elements of the engine is provided, because the operation of the oil pump directly depends on the engine turned on.

It should be borne in mind that, unlike starting on a hot one, a short time can fluctuate for a short time in an unheated motor, as the electronics provide for a start level of 2000 rpm, and a little later it lowers to standard values of 900–800 rev / min. Such a variability of the functioning of the injector may be perceived by some motorists wrong. In this case, the main task, which was invested in a similar algorithm, was associated with the improvement of environmental friendliness.

With cold internal combustion engines, the catalytic converter responsible for reducing the concentration of harmful emissions does not start up. In this case, due to the increase in speed, the system tends to quickly increase the operating temperature of the engine, bringing it to the desired operating mode. Bringing to the required level, the electronics reduces the number of revolutions.

At high speeds, the engine warms up more quickly, which significantly increases the fluidity of the lubricating fluid, allowing it to be distributed over all the desired surfaces. A normal phenomenon is considered to be a variant in which, after a brief set of high revolutions, a gradual decline and stable maintenance of small values. If, however, revolutions are floating on a warm engine within 500-1500 rpm with a constant sharp drop in the arrow, this is evidence of problems with the engine.

At high speeds, artificially supported after pressing the pedal, swimming can disappear, and when falling - everything returns. It is not worth the risk on such a machine, because it can stall at any intersection, causing an emergency.

Popular causes of engine instability

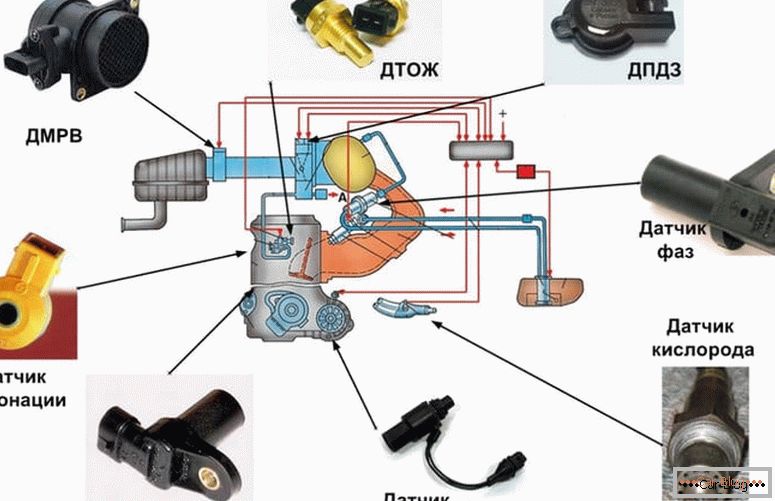

In addition to these reasons, there may be other factors that have a negative impact on the performance of the motor in the car. It is important to know that information is being collected from different sensors. It enters a specially installed electronic control unit. Based on the algorithms embedded in the electronics, the engine is controlled. Having understood which sensor is responsible for engine revolutions, it is possible to identify the causes of failure.

See also: What does the color of spark plugs meanIt is necessary to monitor the state (operability) in the following sensors:

- speed;

- idle move;

- throttle position;

- crankshaft position;

- air flow.

Based on this list, the most popular reasons for which rotations on a cold engine float are:

- for carburetor engines, a no-load valve, providing the necessary amount of fuel for the combustion chamber, may be a problem area;

- leads to trouble clogging in the air filter or significant soot on the candles;

- it is necessary to check the ignition coil or its winding, as insulation breakdown will occur;

- burned down gasket between the intake manifold and the cylinder block can cause a negative;

- high or low voltage wires suitable for the ignition coil.

A visual inspection of the engine compartment can help in the decision, because the physical deterioration of a fuel cell can create instability.

The more difficult problems of motor performance include the following factors:

- computer failed;

- сомнительная работоспособность датчика idle move;

- breakage of the camshaft sensor;

- dropped fuel pressure;

- ignition commutativity is lost;

- DFID does not function.

Usually such situations have to be resolved with the help of experienced specialists, because in the process of diagnostics it is often revealed that the reason lies in several breakdowns. Also, in order to check whether the speed due to the generator can float, it is necessary to fold the wires from it with a well-charged battery and look at the result. In the event that malfunctions remain, the culprit is not this appliance. Otherwise, it is necessary to conduct a thorough diagnosis.

Bringing the internal combustion engine to stable operation

After a thorough diagnosis and determine the reasons, it is necessary to begin to eliminate them. To do this, you must perform the following steps:

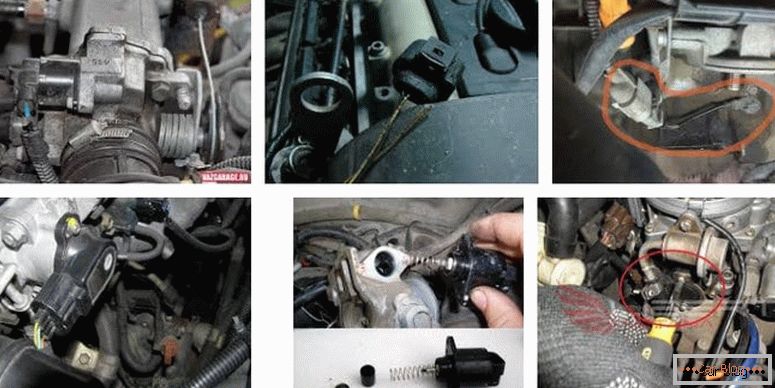

- After disconnecting the oil sump we clean the valve from accumulated oil contaminants. After dismantling, we wash the body part in kerosene beforehand, and dry it. If necessary, we carry out a complete replacement.

- We provide crankcase ventilation. While the engine is running, oil and fuel residues are burning. In the power block, an increased gas pressure is formed. It periodically reduces the system due to the built-in valves for pipes of complex geometry. Timely work on cleaning VCG minimizes fuel consumption, will balance the speed and will not allow excessive consumption of lubricating fluids.

- An important factor is the timely diagnosis of highways that supply air to the fuel mixture. Channels are checked for tightness visually or blown by a compressor (electric or manual). Unwanted cracks or holes can provide additional unrecorded air leakage, which leads to imbalance. To identify problem areas using WD-40. If there are cracks in the pipelines, then the lines are completely replaced, since such elements cannot be repaired.

- Pay attention to the throttle. It is flushed from the layers formed from the burnt oil. Reconfiguration after dismantling will be required. We unscrew the fastening bolts and disconnect the hoses, and we consider the valve itself for wear or mechanical damage. For cleaning, use a spray aerosol from fats and a special brush. After flushing all the planes set it back and set the adjusting clearances.

- If, after cleaning the throttle body, engine revs are floating, then the air flow sensor may fail, which cannot be eliminated by itself. It will only need to be replaced with a new one.

- A failed solenoid valve, located in the carburetor fuel supply system, is also capable of causing engine speed drops. With such a breakdown will need to be replaced. However, if this happened along the way, then a completely open suction will help to get to the nearest station.

- Clogged jets in the carburetor do not always need to be unscrewed. For their cleaning is required to use an aerosol agent. After this treatment, it is recommended to blow the canals with compressors, getting rid of possible residues of garbage.

- Removal of corrosive traces on the surface of the blades of the fuel pump is carried out using the XADO VeryLube. Any similar remedy from other manufacturers will do. The composition must be sprayed through the neck of the empty fuel tank immediately before full filling. When this occurs, the sedimentation of the substance on the desired surfaces, where the composition reacts with pollutants. Chemical neutralization is carried out by the method of adding engine oil. About 120–150 ml of liquid lubricant are added to the fuel tank for diesel fuel. After that, it settles on the metal blades, providing a protective film, blocking the appearance of corrosion centers.

A more complicated process is a flashing of the ECU, if circumstances so require. Failures may occur in the event of mechanical damage to the device or its individual components. However, according to statistics, this happens very rarely. It is preferable to make changes in the software part of the car should contact the specialized branded centers.