Puncture tires almost any driver will be able to fix it yourself. This is especially true in the case of a problem spare wheel or simultaneous multiple puncture wheels. In his own garage for this should be a set for the repair of tubeless tires, which will come to the rescue of a competent car owner.

In addition, the driver will save money on repairs, he will be able to get rid of punctures on his own at any time, without the help of the repair company’s employees.

Content

- 1 Tire type determination

- 2 How to identify the puncture zone

- 3 Preparatory work

- 4 Repair

- 5 Dealing with other defects

- 6 Conclusion

Tire type determination

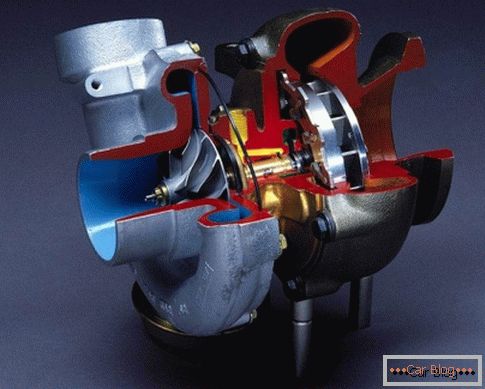

Before you repair, you must definitely decide on the type of rubber that is installed on the car. The difference between chamber and tubeless wheels is that secondly there is no additional element - a rubber chamber filled with air. Instead, there is a thin, not more than 3 mm thick airtight layer inside the tire.

It fills the pump or compressor during tire inflation. Restoring the integrity of this cavity is the main task of the process. Usually it takes about half an hour, and the cost of resuscitation practically does not exceed 200-400 rubles.

Tubeless tires can be of two types:

- self-adhesive;

- standard type.

For the first option, the minimum amount of air is weathered through the puncture. This type is the safest to drive on problem roads. For the second type, it will be necessary to plug the hole with a screw. This will allow you to reach the garage or the nearest repair shop.

With a repair kit, you can even repair a side cut of a tubeless tire. The advantages of operating this rubber are in the following positions:

- safety is higher than that of wheels with cameras;

- significantly less heat while driving;

- longer service life;

- less weight when compared with chamber counterparts.

Almost all cars manufactured over the last 5-6 years are equipped with this type of wheel rubber. Even in the behavior with a puncture, we can distinguish a tubeless wheel, which descends much slower than the chamber copies.

Before you repair the tubeless tires with your own hands, you need to make sure the type of wheel. It is customary to pay attention to the nipple. For chamber wheels, it will have a tapered or cylindrical appearance, while for tubeless wheels there will be a slight seal at the base with a visible collar. The latter is necessary for locking the air inside the cavity.

See also: How to determine tire wearIf the driver is not sure, then he may try to push the nipple inwards, if successfully tried, the wheel will be with the camera.

How to identify the puncture zone

Not every situation can immediately determine the point through which the wheel is lowered. This is due to the fact that air leaks occur in different zones:

- the air is vented through the nipple;

- fit to the sides is not tight enough;

- weak valve mounting;

- prolonged use of the wheels without additional pumping.

When mechanical damage occurs most often the surface is broken by metal pointed elements or broken glass. In order to detect leaks, a foamed soap solution or another similar mass is applied to suspicious zones, and the pumped wheel can be fully lowered into a container with water. A puncture will reveal itself with air bubbles.

If the application of the soap solution did not succeed, you can turn the wheel not a full turn and repeat the procedure, and then use the tubeless tire repair kit.

Preparatory work

Identified puncture or sticking stranger will fix it yourself. Difficulties may arise in repairing damage of more than 5 mm in diameter. Small punctures are repaired more easily.

You need to know that you can often eliminate the puncture without even removing the wheel from the seat.

The kit must include the following components:

- a device that expands the impulse;

- raw rubber band;

- auxiliary elements for the installation of the harness;

- special glue or paste for repair.

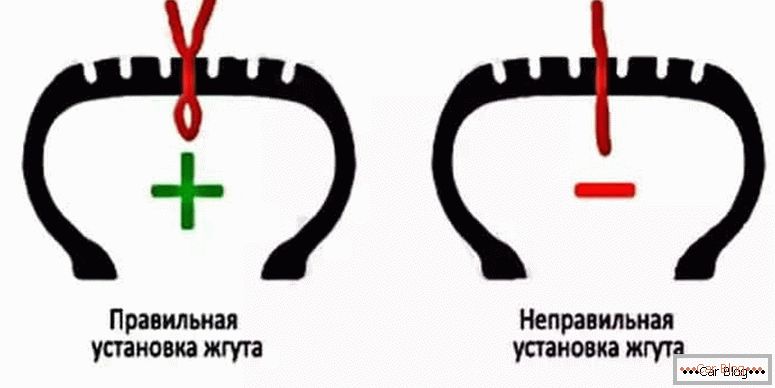

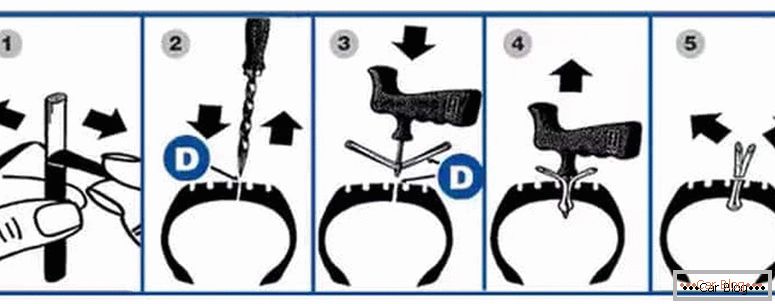

You will also need a sharp enough and durable knife that can process a reinforced plait that is problematic for cutting. When selecting the hole spreader, it is necessary to take into account that all the layers are sufficiently dense, and the working part of it must pass through all the layers. In the classic repair kits, its role is performed by a tapered file with a T-shaped handle. With this form, it is easier to overcome the resistance of rubber.

A device for inserting a harness is also an integral part of the kit. With the help of a special cut, fixation of the patch is carried out below. After removing the steel rod, the raw rubber band goes into the cavity and remains there. Most latok withstand many tens of thousands of kilometers.

Repair

After preparing the tools and identifying the puncture site, you can proceed to repair. First of all, the place of processing is pre-cleaned. Next, we determine whether it will be possible to patch up the problem area with the harnesses that are available, since it is possible to handle punctures up to 5 mm on our own.

You need to know that several harnesses will help you get to the service center when there is no possibility to call a tow truck, and the wheel has a significant puncture.

When working with the wheel pressure should be about 0.5 atmosphere. Such a parameter will provide sufficient flexibility to the rubber, removing excessive stresses. The puncture tool is placed with a T-shaped handle and scrolls several times and then removed. We repeat this operation two or three times.

See also: Is it possible to restore spikes on winter tires with your own hands

In the resulting space, we mount a special harness, which is smeared with special adhesive or special paste in advance. After that we give a little time to dry and inflate the tire to the working pressure. Apply a little soap solution to the treated area to check the quality of the patch. When air bubbles appear, the operation is repeated. Detailed work can be viewed on the video presented on the page. The excess "tails" of the rope are cut off with a sharp knife.

You need to know that the mass of the harness does not have a significant impact on the wheel balancing, so the ramp does not need additional operations.

Dealing with other defects

Carrying out repair work with tubeless tires is not only to eliminate pinpoint radial punctures, but also to get rid of other damages that interfere with normal driving. However, not all of them will be able to eliminate even in qualified tire enterprises.

Most often, such problems include lateral damage to the tire. This is usually the final sentence for the wheel. In non-critical cases, you can restore the slope and throw it in the trunk as a spare wheel. Before this, it is desirable to balance the wheels.

Side cuts often tear the cord, and after that it is difficult to predict the behavior of a car with such a wheel. Correct the situation can vulcanization with a patch from the inside. A well-established patch can last for many years.

For bending discs on the road, you can pre-align the sidewall with a hammer to get to the service station. On discs damaged by corrosion processes, a special sealant is used. The contact area with the disk is processed along the entire perimeter.

If for some reason the spool or nipple is damaged, it is necessary to replace them. Long ride with damaged will not succeed.

Conclusion

Even a novice driver can carry out a small repair of tubeless tires. Repair kit can be carried in the trunk. More serious impulses or large lateral cuts will have to be entrusted to specialists.