>

One of the main accessories that modern car needs is to protect the engine crankcase. The plate for the bottom of the engine compartment is not mandatory equipment, so many manufacturers either equip the car with an unreliable plastic sheet or leave the crankcase completely unprotected. At the same time, the risk of hitting an obstacle that is not in the driver’s field of view exists even in the city.

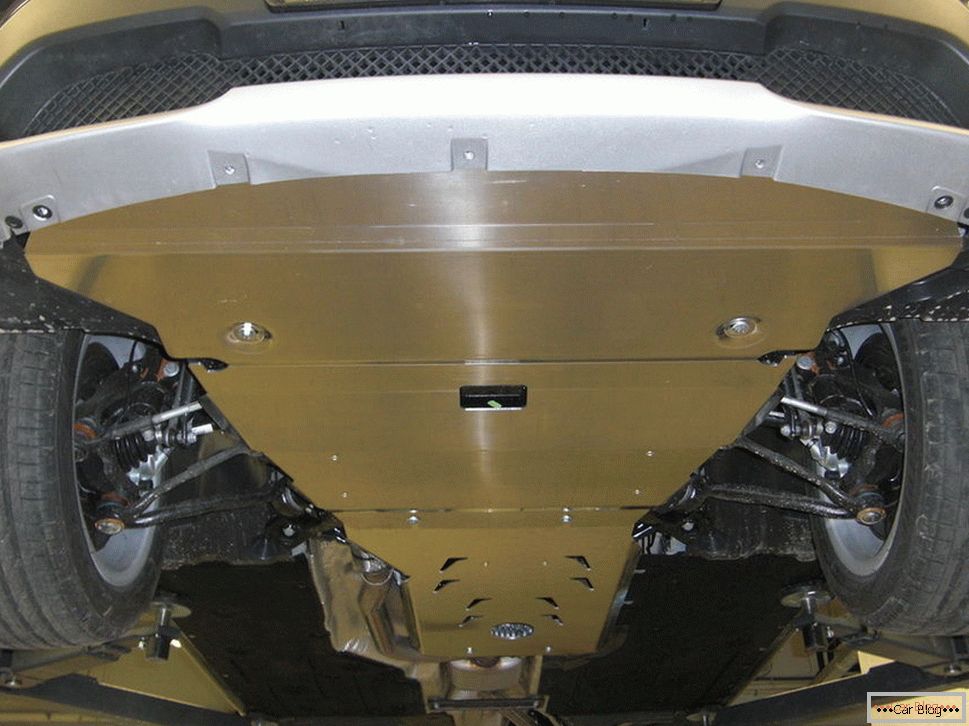

Automobile with engine crater protection installed

Protection of the crankcase saves the car engine from mechanical damage, such as stones, boards, fittings, as well as the damaging effects of dirt, sand and snow falling into the engine compartment. Particularly relevant plate to protect the crankcase on Russian roads - harsh weather conditions in conjunction with the features of the landscape can make the trip a real test of the car for durability.

Читать далее о как выбрать защиту картера двигателя-->Несмотря на всю важность пластины для защиты картера, к ней проявляют малую ответственность не только производители автомобилей, но и водители. Многие автолюбители не заменяют заводскую защиту либо вовсе отказываются от её установки. Такое поведение создаёт риск серьёзной поломки двигателя или коробки передач. Вышедшая из строя ходовая система не только отнимает время и средства на ремонт, но и может подвести водителя в критический момент на дороге.

What is a crankcase protection?

Protection of the engine compartment of the car - a sheet of metal or other durable material that has a special shape, suitable for a particular car. It is mounted on the bottom of the car, saving the suspension system from damage that may be caused by obstacles, dirt, dust and fluids on the road.

Most often, off-road vehicles, which often travel over rough terrain, need to protect the engine crankcase. Also in the plate need a machine with low ground clearance and those that are operated in harsh conditions. Full crankcase protection is different from that established by many manufacturers - it has high strength and reliability.

The protection of the engine crankcase does not apply state standards. Due to the lack of control over such an important part, many drivers refuse to install the plate for one reason or another. It also allows engineering companies to pack their cars with a weak and sometimes decorative plate.

Despite the fact that the purpose of the plate for the bottom of the engine compartment is clear and simple, the choice of protection requires knowledge of the differences of parts from a particular material. It is desirable that the plate meets a number of general requirements, as well as suitable for a particular car and the conditions in which it is operated.

Why crankcase protection?

Many owners, on whose cars the factory plate is installed or are completely absent, underestimate the importance of high-quality protection. Statistics show that even on a seemingly level road there is a risk of damaging the chassis. Repairing an engine or transmission costs a lot of money, but the systems can be protected by timely installing crankcase protection. Many understand the need for this part of the car only after they get into an unpleasant situation that could have been avoided.

The need to protect the crankcase of a car engine is due to the fact that it is subjected to a series of strength tests daily. Snow and rain, constantly falling on the bottom of the car, can cause the body to be covered with corrosion. As for the collision with an obstacle like a cobblestone, wooden or metal construction, a piece of ice or asphalt - such obstacles can not only entail serious waste, but also put the life of the driver and passengers at risk.

In addition to the function of the shield and the mudguard, the plate to protect the crankcase has another purpose. She protects the car from intruders. The hijacker who tries to get to the wiring under the hood of the car will face problems connecting the system to break the alarm. In addition, an attacker trying to disable the electronic control unit will have to twist the crankcase protection, which will allow the owner of the car to gain time.

Thus, the installation of high-quality and reliable plate to protect the crankcase allows the car owner to protect themselves from the waste of time and money, as well as damage to health, which may be caused by an emergency situation.

Types of crankcase protection material

In today's market there are many offers plates for the bottom of the engine compartment. Their main difference is the production material. Each species has its advantages and disadvantages. The choice between them is based on requirements and budget.

Steel

Steel crankcase protection elements are the most common. The reason for their popularity is good reliability, maintainability and affordable price. The steel plate is easy to repair, and a standard thickness of 2-3 millimeters allows you to protect the chassis from most of the obstacles on the road.

Steel crankcase protection for Volkswagen Passat B6

The disadvantages of steel elements include a tendency to corrosion. They quickly become covered with rust, which over time leads to serious defects. Even an anti-corrosion coating does not protect against this effect.

The life of the steel plate depends on driving style, frequency of travel, the quality of the road surface and the ambient temperature. On average, an element serves for three to four years.

Two-millimeter protection is suitable for all cars, while the three-millimeter one is designed for some off-road vehicles - it is heavier and more difficult to repair.

Aluminum

In addition to steel, there is also an aluminum crankcase protection engine. These two types of plates have nothing in common. First of all, aluminum protection costs about 4 times more than steel. Aluminum plates are usually 5 millimeters thick, but they are identical in weight to 2 mm steel plates.

This type of plate has several advantages in operation. The rigidity of aluminum allows you to perform the entire protective system as a single element - it is easy to remove and install. In addition, these plates do not create sparks on contact with any surface, which nullifies the flammability of their use.

Aluminum crankcase protection

The disadvantage of aluminum protection is its tendency to oxidation. Despite the fact that this type of corrosion does not affect the technical condition, the appearance of the plate deteriorates. Occasionally, the fastening of the sheet is oxidized, making it difficult to remove. Also, aluminum elements have a high cost.

Stainless steel

Analogue of steel plates, which is not subject to corrosion. As a rule, stainless steel protection is made by pieces, since the manufacturing process is complex and difficult. Plates of this material have a high cost.

Stainless steel motor crankcase protection

The benefits of stainless steel protection include an attractive appearance, corrosion resistance and high strength. Most often, these plates are installed on expensive SUVs  Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru .

adom.ru .

Titan

These plates combine the advantages of aluminum and stainless. Titanium is a light metal that is almost not susceptible to oxidation.

The disadvantage of titanium protection is its high price. It is reasonable to install it only on expensive cars. Titanium plates, like stainless, are made piece.

Titanium crankcase protection

Composite material

The engine crankcase protection of the composite is the second most popular plate type. The most common is fiberglass option. Production technology involves the connection of several layers of materials with different properties, the combination of which allows to achieve the desired properties.

Composite plates have high strength. In addition, the cost of elements of this type depends on the specific species, so you can choose the protection of any price category. Fiberglass will cost the least. More expensive - Kevlar.

Crankcase protection from composite material

The disadvantages of all composite plates are the possible toxicity with strong heating, as well as the price, which increases with increasing quality of protection. In addition, there are many defective composite plates on the mass market, since the technology for their production is rather complicated.

How to choose crankcase protection

First of all, you need to decide in what road and weather conditions, as well as in what driving style the plates will be used. Each driver will suit your type of protection material.

It is necessary to find out the desired plate thickness. This parameter depends on the material production and the purpose of the item. Thickness largely affects the degree of protection.

Also important is the weight of platinum. Too heavy sheets on light vehicles can lead to a significant decrease in dynamics.

Another important parameter is the quality that a particular manufacturer provides. It is recommended to purchase plates from reputable dealers, and install them from experienced craftsmen. In this case, the protection will be the most reliable.

The last parameter is the cost of the plate. Depending on the budget, the driver can count on different types and variations of the protection of the crankcase of the engine. It should be noted that one of the most popular types - plates of steel - have an affordable price.

Total

Protection plates for the engine crankcase are optional. However, installing a quality sheet on the bottom of the engine compartment can save the driver from wasting time and money, and most importantly - to protect health.

On the modern market there are many models available for any purpose and for any budget. The choice depends on the personal preferences of the driver. It is strongly recommended to consider the options yourself, as the images on the Internet or the journal do not convey all the details.