The most intensively used elements in the cabin are the steering wheel and pedals. The state of the latter is not so noticeable to the driver and passengers, but the steering wheel should always cause pleasant tactile sensations. Pushing the steering wheel with your own hands will help to give it a personality and a stylish look.

In addition to aesthetic perception, the “steering wheel” should be securely fixed in the hand so that the driver could react to road surprises in time. Therefore, it is necessary to choose high-quality, tight-fitting material, eliminating slippage or other troubles.

Content

- 1 Selection of materials for tuning

- 2 Required materials and tools

- 3 Skin steering wheel do it yourself

The choice of materials for tuning

As a material, it is desirable to use soft skin with perforation. It is better fixed by hand and has a good coefficient of friction. Before you trim the steering wheel with your own hands, you need to choose the color and texture of the material. The cost of the material and its compatibility with the rest of the decor in the car depends on it. It would hardly be appropriate to have a black steering wheel in a chic beige interior.

Leather sheath on the steering wheel

Buying upholstery fabric, you need to choose it with the ability to purchase, if necessary, another piece. When the firmware can happen different situations, as well as when cutting the canvas. It is advisable to stock up on the possibility of adjustments so that you can properly restore the skin on the steering wheel or create a new pattern.

Required materials and tools

Ensuring quality results can be achieved with the following components:

- High quality upholstery material;

- Babina synthetic durable threads of the desired color;

- Steel hardened needles for skin, with a material hardness up to 45-50 HRC;

- A pair of thimbles to push the needle;

- Roll of construction tape;

- A3 format cardboard for pattern making;

- 10 m roll of cling film;

- Marker with a thick rod;

- Nail scissors or sharply sharpened knife;

- Two-component skin glue or epoxy;

- Hair dryer for drying powerful home or industrial.

-

- Step 1. Form the pattern for braid

-

- Step 2. Try on the stitched workpiece on the steering wheel

-

- Step 4. We sew upholstery on the steering wheel

-

- Step 5. Fasten decor and buttons

Skin steering wheel do it yourself

Determine the number and shape of blanks for the material can only be experienced. For this you need to create a pattern. Automotive enterprises producing mass-produced products receive a ready-made pattern from engineers and designers. With self-repair, we will use detours.

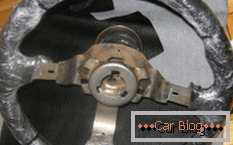

Initially, you need to make a cast from the surface of the “donut”, and then, dividing it into separate components, to form patterns for the finished product.

Food film will serve as the basis for the frame. She wrapped all the surfaces where the steering wheel skin. The next layer is formed with the help of molar scotch. It should be very tightly envelop all the required areas. No swelling or sagging should be allowed. All cuts will adversely affect the fixation of the upholstery fabric.

Marker markup for separation the resulting billet. Connecting seams will run along the marked bands. It is advisable to cut them so that they were not visible. Each part is numbered in a certain order and draw up a diagram of the future assembly. Cut with a scissor or knife pattern along the established lines.

Having removed all parts of the workpiece from the wheel, they need to be straightened with the help of a weakly heated iron (do not forget to save tape and film) or stack something heavy (weights, a bucket of water, a cupboard). The straightened elements are transferred to the cardboard, not forgetting to add an allowance of 4-5 mm to the seam, and also to remove 2-3 mm along the connection around the rim, considering that the measurement was carried out along a larger diameter.

Stitching upholstery on the steering wheel

Experienced specialists, who not the first time do such an operation, can skin the steering wheel with their own hands without gluing parts, but for beginners it is preferable use epoxy resins or glue. So the measurement and manufacturing errors are being concealed a little.

During car trimming with an airbag, care must be taken to prevent unauthorized operation. For convenience, you can fully dismantle the wheel and do the firmware from any side in convenient conditions.

See also: Why windows get fogged up in the carThe new upholstery is practically laced over the stitched machine in advance at the edge of the holes. They can be pierced with an awl on their own, but it is better to entrust this painstaking work with a sewing needle on the machine.

Experienced masters pre-moisten the skin in warm water. So it becomes more elastic. After drying, the material fits more closely to the surface by reducing the size.

After completing the firmware from all sides, and drying the surface with a hairdryer, you need to let the glue dry, and only then return the steering wheel to its place. After that, you can put the buttons, decor, pillow into place. Fans of self tuning often with such an operation mounted steering wheel heating.