>

The importance of maintaining the brake system in good working condition is understood by all drivers, but when it comes to choosing brake pads, the desire to save often leads to disastrous results. Poor-quality products, which literally flooded the market, do not provide a reduction in stopping distance to standard indicators. And even the deterioration of feedback between pressing the brake pedal and the actual braking can not be called the most negative consequence of a wrong choice. Bad pads are capable of literally a month to erase the drums and discs to such a state that it would require expensive repair of brake mechanisms.

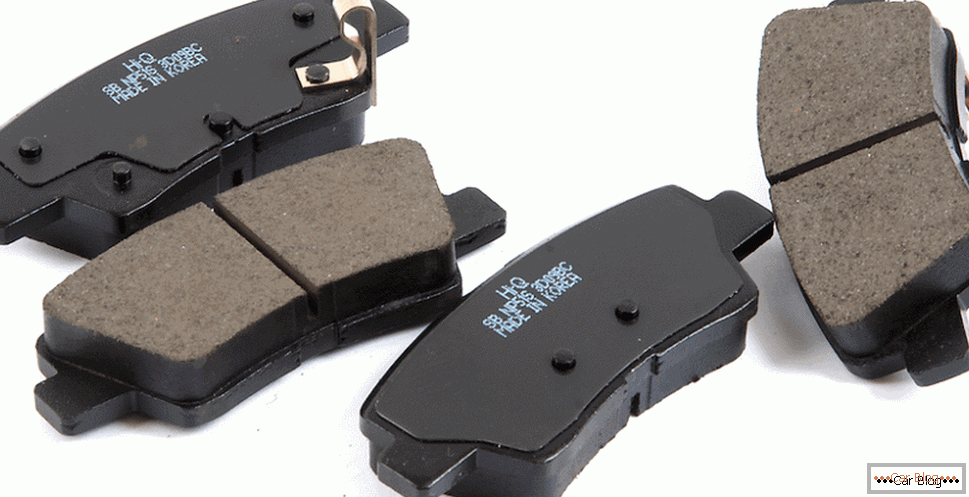

When choosing pads avoid counterfeit products.

The right choice for the VAZ family of cars is especially relevant, since it is the one that is most affected by counterfeit products.

But before advising the best brake pads on the VAZ-2110 and other modifications of the domestic car brand, we consider it necessary to describe what these products are and what are the main criteria that should guide their choice.

Brake pad classification

There are two main criteria that are taken as a basis for the classification of pads: the material of manufacture and the method of their fixation.

According to the first parameter, the brake pads are divided into:

- organic;

- metal;

- from ceramics;

- semi-metallic.

Consider the advantages and disadvantages of each of the above varieties.

Organic brake pads

This type of pad is characterized by a multicomponent composition - they are made from Kevlar with the addition of rubber, glass, high-temperature resins and carbon materials. The advantages of such products - their softness and low noise when braking. However, the organic pad has enough disadvantages: low wear resistance, deterioration of adhesion and an increase in the braking distance when moisture gets on the pads. From the point of view of ecology, despite the name, these products are also difficult to call ideal, and their ability to form large quantities of dust leads to the rapid clogging of the ventilation holes in the brake discs and their overheating.

Metal pads

The composition of this type of pad is again displayed in the title with a certain degree of conditionality: it is similar to organic products, but with the addition of metal components, which are usually steel or copper. Due to this, the wear resistance of such pads is higher, which improves braking efficiency. Their other advantage is the ability to significantly improve heat transfer, which is especially important for drivers who prefer aggressive driving style. However, the metal brake pads are far from ideal indicators in terms of wear rate, and they are more expensive than organic ones.

Ceramic pads

The most common variety. Despite the fact that their cost is the highest, in all other respects they are undoubted leaders. The composition of the upper friction layer is a mixture of non-ferrous metals, a small amount of iron and ceramic fibers. Such products are much less afraid of water ingress, tolerate increased thermal loads, are characterized by excellent braking properties.

They have the ability to warm up not as intensively as other varieties, they do not wear the brake discs so much and practically do not emit fine dust, keeping the ventilation holes in working condition.

Ceramic brake pads are not very hot

Semi Metal Brake Pads

The composition of the pads of this type is characterized by different content of metallic impurities - within 30 - 60% (as a rule, it is copper or steel). The remaining components are various inorganic materials and graphite. Typically, the semimetallic pads include a special friction modifier that promotes better bonding of the other components.

This type of product boasts good heat dissipation, but otherwise they have the same drawbacks as other pads, with the exception of ceramic ones: they wear out quickly, are noisy when braking, do not tolerate negative temperatures, increasing the braking distance in winter.

In general, it should be noted that the requirements imposed on the material for manufacturing brake pads are contradictory in many respects, so manufacturers tend to find a reasonable compromise between such characteristics as heat resistance, wear resistance, ability to retain their properties when moisture enters and so on.

It is no secret that sudden braking is the increased friction between the brake disc / drum and the friction surface of the pad, resulting in the release of a huge amount of heat. Low-quality products with a sharp rise in temperature are covered with a slippery glassy crust, which significantly reduces the braking efficiency. The addition of special fillers that increase the thermal conductivity of the friction material, facilitating the rapid transfer of heat to the substrate, usually reduces the wear resistance of the product.

When choosing brake pads for VAZ-2107, 2110, 2112 and other models, give preference to ceramic products with reinforcement, as they have the least effect on brake discs. Pads made using non-ferrous metal chips are a little inferior to them.

According to the type of fixation to the metal plate, the pads are of two types: riveted and glued. Despite the apparent fundamental difference between these fasteners, in fact, their performance characteristics are approximately equal.

Glued pads

Friction linings are fixed on a metal base with a special adhesive composition with deep penetrating characteristics. The advantage of glued pads is the possibility of their use until almost complete wear, which increases the resource, but at the same time carries the risk of damage to the brake disc, so for this type of products it is important to monitor their condition and change them in time, preventing full wear.

riveted pads

The reliability of the riveted connection in this case is comparable to the adhesive, and the resource of such pads is somewhat less. But the driver can determine the degree of wear by purely external signs - by the characteristic creak, which is made by rivets rubbing against the disk. Looking into the brake mechanism in this case is not required.

Important parameters when choosing brake pads

When choosing brake pads for Kalina and other VAZ models, it is necessary to take into account that the problem of the existence of fakes currently remains topical, which is largely due to the imperfection of current legislation. Therefore, such purchases are recommended to make in company stores that are not interested in the supply of products of dubious quality. On the contrary, small outlets are practically not responsible for poor-quality products, attracting buyers with low prices and many other marketing gimmicks.

So, what you need to pay attention in the first place:

- certificate availability - the packaging of the pads must contain a mark of conformity of the proposed product to the ECE criteria (marking - 90R / R90);

- an external examination of the friction layer can also provide an invaluable service: the presence of foreign substances on it should cause suspicion, although the presence of such minor defects as small chips, cracks, dents or bulges are permissible;

- Pay attention to the metal base - it should be smooth, without visible bends, even microscopic detachment of the friction material should be absent;

- Pay attention to the indicator of the operating temperature of the acquired shoes - the higher the value, the better the braking efficiency. For most VAZ models, this figure is in the range of 280 - 350 ° C. At the same time, it does not make sense to overpay for expensive products that can withstand temperatures of 800 ° C or more.

Marking

An experienced motorist can be told about the quality of the pads as an external inspection, and product labeling. Most motorists on the last factor do not pay attention, and completely in vain. So, one of the most important indicators of braking efficiency is the coefficient of friction, denoted by two Latin letters, which correspond to certain numerical indicators

The first symbol indicates the average coefficient of the block when it is heated, the second - after complete cooling.

Table of values of the friction coefficient (the larger the value, the more efficient the braking and the higher the wear of the pads):

- C - less than 0.15;

- D - CT equal to 0.15 - 0.25;

- E - the value of the coefficient lies within 0.25 - 0.35;

- F - coefficient of friction is 0.35 - 0.45;

- G - AI = 0.45 - 0.55m;

- H - the coefficient of friction is 0.55 - 0.8.

Unfortunately, not all products present in the domestic market have this labeling.

In addition to the friction coefficient, the marking may include the following information:

- compliance with the EU certificate (we have already talked about it, it is designated by the symbols 90R or R90, followed by the approval number);

- catalog number HEXEN;

- designation of the production batch;

- WVA number defining the pads geometry.

Here you can find out the country in which the product was manufactured:

- E1 corresponds to Germany;

- E2 points to France;

- E3 is Italy;

- E11 denotes a manufacturer from the UK.

Brake pad rating for VAZ

As a rule, many automotive parts and mechanisms are tested on special stands. No exception and details of the brake system. According to the results of bench tests and reviews of motorists, the best brake pads for the VAZ (2110, 2112, 2115, 2117, that is, for almost all families, including the "classics") TOP-10 has the following appearance:

ТИИР

Established pads for the WHA

The pads of this oldest domestic manufacturer of friction products are regular for VAZ vehicles (TIIR-206, TIRR-240, TIIR-260). Do not contain asbestos, have high braking efficiency, stability of friction characteristics, are able to maintain their properties when heated to 700 ° C and subsequent cooling. Wear resistance is not the highest, but the pads have a minimal effect on the braking mechanisms. The products use an adhesive method of fastening the friction material to the base, which is distinguished by high reliability - there were no cases of detachment under normal driving conditions. However, for drivers who prefer aggressive driving style, TIIR products will not be the best choice, because when overheated, they become ineffective due to glazing of the upper layer.

ATE

Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru ATE products may be the best choice among others.

adom.ru ATE products may be the best choice among others.

If the price factor for you is not deciding what is the de facto standard in relation to the brake system, then products under the ATE brand may be truly the best choice. These are the best brake pads (rear and front) for the Kalina, Priora, Samara, Samara 2 families, characterized by soft but effective braking, quiet operation, and the ability not to lose their performance over the entire life cycle (until critical wear).

The use of innovative materials and technologies, as well as time-tested formulations for the manufacture of friction materials (with the inclusion of non-ferrous metals - nickel, titanium, chromium), make this German ceramic product a luxury class. The huge model range allows you to choose pads for almost all VAZ models. Their only drawback is the high cost, but driving safety, as they say, is priceless. It is necessary to be afraid of fakes, therefore it is necessary to buy ATE pads in company or large automobile shops.

STS

Products meet European quality standards.

Despite the fact that it is a domestic manufacturer, the company actively cooperates with German brands specializing in friction products. This allows STS to produce brake pads, which are not inferior in quality to imported ones, but cost much less. The company's products fully comply with European standards in this area, which allows it to be installed on domestic cars, as well as on KIA and Renault cars assembled in Russia as part of joint production.

Differ in quite good wear resistance, rather high resource.

Dafmi

You can detect the presence of squeaks in the pads of this brand.

At cost, the brake pads of this brand are slightly more expensive than the original ones, but their wear resistance is noticeably higher. According to numerous tests, they are also not a suitable choice for lovers of sudden and frequent braking, since overheating may experience an increase in the thickness of the friction part, threatening to peel it from the base. Many consumers note the presence of squeaks on undeveloped pads, which eventually cease.

In general, these products can be recommended to those drivers who prefer a quiet ride and do not often like to replace them.

Allied Nippon

Quality pads made in Japan

Can Japanese products be of poor quality? The overwhelming majority of domestic motorists have no doubts about this. A good example of quality is the brake pads from the world-renowned Allied Nippon company. Although the concern specializes in the production of various auto parts, special attention is paid to the friction division here. Many models are optimized for VAZ products. The original production technology of the friction lining involves the use of ferrocarbon - a modern material of mineral origin, which allows to increase the durability of the pads with a quite acceptable heat transfer rate. If you ask yourself what kind of brake pads should be put on Grant or Kalina, then the best answer to it will be Allied Nippon products. In any case, the ragged driving rhythm characteristic of megacities, it can withstand better than most competitors. Of course, you have to pay for good quality. If you have no problems with finances, Japanese shoes will definitely be a good choice.

ROSDOT

These pads have durable characteristics.

Another domestic manufacturer of brake pads has a rather extensive assortment capable of covering the needs of almost the entire modern AvtoVAZ model range. At a reasonable price, this product has quite decent wear-resistant characteristics, good heat dissipation, low noise (due to the use of original Italian mastic with anti-noise properties).

Among the advantages of RosDOT products are the absence of harmful substances (lead, asbestos, copper) in the composition of the friction material, which allows them to comply with the EU Directive on Safety 2000/53.

TRW

Pads with good braking performance

Specialists of the British company Lucas in their friction materials have focused on providing excellent braking performance - according to this indicator, TRW pads are considered among the best. Of course, this is done at the expense of quick wear. In case of late replacement there is a risk of damage to the surface of the brake disc. The price of products under this brand is quite adequate, the quality can not be called even average, so it is not surprising that the TRW / Lucas brand is present in the assortment of most auto shops.

The model range is distinguished by a large variety, without problems, you can pick up the front and rear brake pads on the VAZ 2107 - 2114. The brand’s popularity also has a downside - too many counterfeit products, so you should buy pads only from trusted and reliable sellers.

Ferodo

Good British brand

The British brand, well-known to Russian motorists, assessed the needs of the domestic market by adapting the value of their products to our realities without loss of quality. Possessing decent wear resistance and an impressive resource, these pads provide quite effective braking even with long-term holding of the brake pedal in the depressed state. At the same time, the noise characteristics of friction clutches also do not cause any complaints, and a rather extensive model range allows you to easily select products for any VAZ model.

MarKon

Good braking performance at a very affordable price is the main advantage of MarKon products. Of course, such pads will have to be changed more often, but this disadvantage is partially compensated by a good indicator of heat removal, which somewhat increases the life of friction clutches.

Democratic value pads

Another disadvantage of the products of this brand is a direct consequence of the insufficient strength of the material - they gather dust, clogging the ventilation openings of the disks.

New pads emit squeaks, mainly due to a slight discrepancy between the pads and VAZ discs, but after grinding, the squeaks disappear. It should be noted and their maintainability, however, only in the factory or close to the factory.

EzATI

Many experts agree that in terms of cost and quality of the product of the Egoryevsky plant of auto parts are considered the best choice for domestic cars.

Brake pads for the entire AvtoVAZ model range - from classics to Lada Kalina and Priory - in many characteristics are not inferior to the best foreign analogues. Possessing good braking performance, they, according to the manufacturer, have a resource in the region of 45 thousand kilometers. Many users who prefer a quiet style of driving, confirm this data.

The main disadvantage of this brand is considered to be a small assortment that makes it difficult to select discs for foreign cars.