>

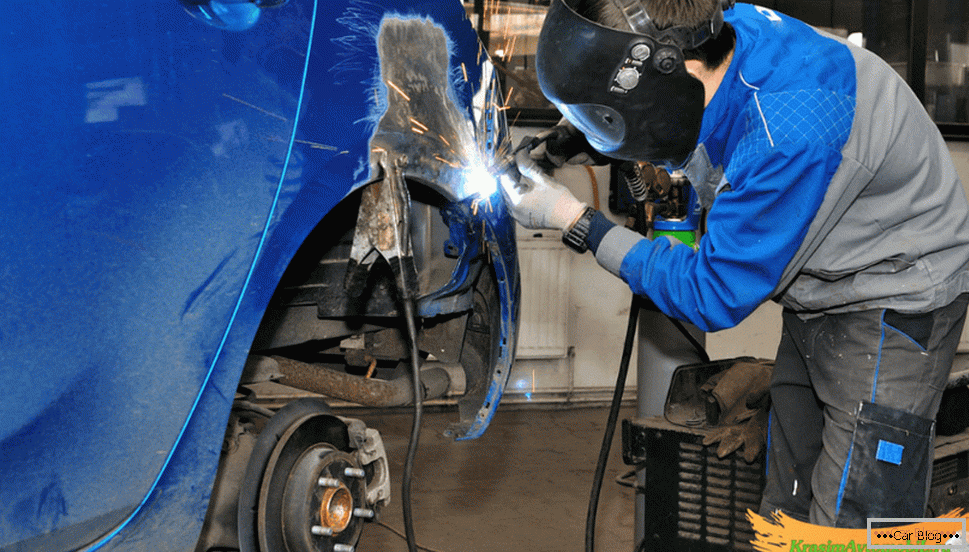

The car body, as the carrier part, requires constant care, periodic repair. Often it is necessary to carry out such repair activities as welding a car. If necessary, it is necessary to weld a necessary element onto the body, a patch, to draw out a dent. Most often, the parts in which moisture accumulates are spoiled: rapids, wheel wings, boot floor, bottom. They rust, corrode, then deform and collapse, and need to be repaired by welding. Many car owners prefer to do it for the sake of cost savings. However, there are many nuances that are important to consider. Let's try to consider which type of welding is better for a car body, the most economical, practical, efficient.

What is required for welding

You have decided to weld your car yourself, without contacting service points, which means you need to prepare:

Читать далее о выборе сварки для кузова автомобиля-->

- welding machine;

- electrodes or special wire depending on the type of equipment;

- protective equipment: mask, gloves;

- electrical network that can withstand the load required for welding.

Selection of welding equipment

AC device

Car owners often choose welding equipment with a working principle based on alternating current. But it is not suitable for work on the body for several reasons:

- welding seams of low quality;

- there are problems with getting the right places by the electrode due to the bulkiness of the equipment;

- with a similar apparatus they boil iron with a thickness greater than that on the body: sometimes 1 mm is burned through, it is better to boil it with a thickness over 6 mm;

- rather complicated tool.

An alternating current apparatus is recommended when simple welding work of a car is expected, such as brewing a burst frame.

Carbon dioxide semiautomatic

This is the most common equipment, successfully used for self-repair of the car. Welding on it is carried out by means of wire entering the work zone. A semiautomatic device is better than the above described equipment for several points:

- welding works are available at 0.8–6 mm of iron thickness;

- seam neat;

- good quality;

- you can use argon, then it will turn out to carry out welding work on non-ferrous metal;

- less experience required: no need to maintain a constant arc;

- material consumption, metal deformation of the car below.

When semi-automatic welding wire is fed into the work area. It serves as an electrode when welding iron at high speed. Metal melts without burning, the elements are securely fastened. The seam obtained after welding with a carbon dioxide apparatus is externally and mechanically very high quality.

The lack of semi-automatic - large size and weight, which led to stationarity of work.

Inverter

Car welding with an inverter is available even to those who have not had work experience. This device is more practical when welding events want to speed up. It uses high-frequency currents - up to 2 thousand Hz. Advantages of the inverter:

- compactness;

- high speed welding;

- an inverter can be boiled at a lower voltage in the network;

- ease of use;

- good quality seams with an inverter even for beginners.

Cons of choosing this device when welding a car:

- expensive;

- welding of metal no more than 3 mm thick;

- extrasensitive.

Of course, in case of damage to the body is better to replace, which is quite expensive. It is also recommended to contact specialists. To save budget  Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru is quite possible to perform welding work on the body yourself, the main thing here is to assess the needs and complexity of the repair, and then watch the video tutorials with tips. With an inverter, even a novice car owner can easily cope with the required volume of activities, other equipment requires skills and handling experience. Choose the option that will be best suited to you, having considered all the pros and cons of different options.

adom.ru is quite possible to perform welding work on the body yourself, the main thing here is to assess the needs and complexity of the repair, and then watch the video tutorials with tips. With an inverter, even a novice car owner can easily cope with the required volume of activities, other equipment requires skills and handling experience. Choose the option that will be best suited to you, having considered all the pros and cons of different options.