Individuality for the car has always been valued highly enough. However, not always the desired result can be obtained quickly, efficiently and relatively inexpensively. For a stylish change in the appearance of your favorite car owners often use tuning body kits. Such decorations can not only isolate the car from the stream, but also to some extent protect it.

After all, for theft, it is unlikely that anyone will covet the conspicuous car. It is easy to see on the streets or parking lots. Therefore, attaching a purchased bumper or installing a spoiler with your own hands, the owner not only makes the car stylish, but also puts a kind of amulet on it.

Content

- 1 Why do you need it

- 2 Stepwise manufacturing algorithm

- 2.1 Foam spoiler

- 2.2 Foam rear wing

- 2.3 Gypsum spoiler

- 3 Conclusion

Why do you need it

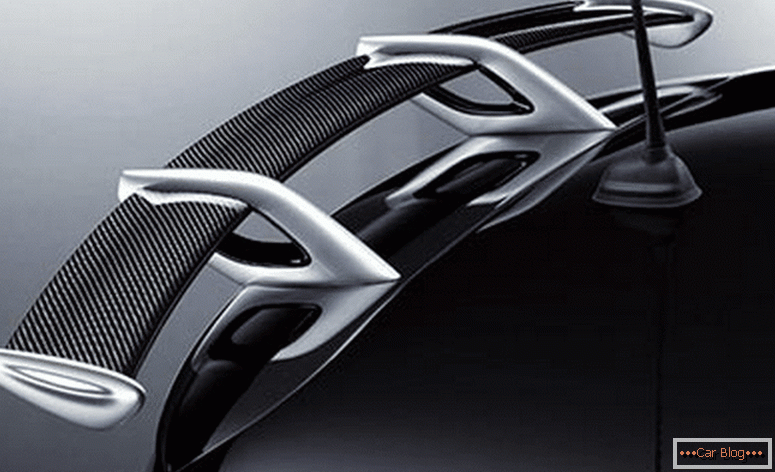

Spoiler mounted on the back of the car, also called the wing profile.

With proper installation and certain calculations, the body kit improves the aerodynamic properties of the machine.

It also helps to reduce fuel consumption slightly, by reducing air resistance, power is added.

Stepwise manufacturing algorithm

To shape the wing, you must make a matrix. It will initially outline the contours of the product. Then the stiffness of the whole future construction is given. At the next stage, the product is applied primer, paint and a layer of automotive varnish. After manufacturing, installation of the finished product is carried out.

Foam spoiler

We will step by step tell you how to make a spoiler with your own hands. One of the most common frameworks for such a body kit is a strip of galvanized iron. At both edges under 90 degrees make two L-shaped bend. On such "legs" in the future, the whole structure will be fixed.

-

- Step 1. Making a metal cork

-

- Step 2. Sticking foam

-

- Step 3. Apply Carbon Fiber

-

- Step 4. Paint and varnish

-

- Step 5. Install on car

After that, the metal "skeleton" should be clouded with foam "meat". White lightweight material without any problems is processed with any saw with a fine tooth and is polished with emery paper.

After preparing the matrix, you will need to fix it with carbon fiber.

It is advisable to apply at least three layers. This will provide high-quality texture and additional rigidity of the product. Between the laying of layers, it is desirable to make small pauses for the resin polymerization. In some cases, you can use an industrial dryer to speed up the process.

Installation of the signal LED backlight is performed at this stage.

So the wires will not be visible, they can be covered with layers of texture, and the LEDs easily embedded in any area.

See also: Why do I need a spoiler on the carAfter complete drying, the surface primer can be applied to impart adhesion properties. Irregularities need to be puttied. This stage forms the final surface. After it will only primer, applying several layers of paint and varnish.

Foam rear wing

To perform this operation, it is necessary to pre-close the upper part of the trunk with plastic wrap. After that, pour the prepared surface with polyurethane foam and wait for drying. Next, with the help of a sharply sharpened knife, we form the product. For finishing you need to work with sandpaper.

-

- Step 1. Zapenevaem basis

-

- Step 2. We cut out the workpiece

-

- Step 3. Apply Carbon Fiber

-

- Step 4. Put the LEDs

-

- Step 5. Sanding with sandpaper

-

- Step 6. Paint and polish

-

- Step 7. Installation on avtomombil

Stiffening is also performed using carbon fiber (fiberglass).

At the final stages, the tuning part is puttied, and then primed, painted and varnished.

Gypsum spoiler

Duplication of spoilers can be done using gypsum. To do this, you need the original tuning part. This spoiler is wrapped with film, and then laid in a foam box. Inside pours plaster solution and wait for solidification. Then gently get rid of the foam, sawing frozen gypsum so as not to damage the original product.

-

- Step 1. We make a casting mold

-

- Step 2. Lay the sample and fill it with plaster

-

- Step 3. Saw the form and remove the workpiece

-

- Step 4. Fill in the shape of the future spoiler and remove it after drying

After that we have a gypsum matrix. We put polyethylene in it as a gasket and pour a portion of gypsum. After opening the halves of the matrix after solidification, take out the workpiece. Further operations are carried out fine-tuning, reinforcement and painting.

Conclusion

In the manufacture of any of the proposed methods, it is necessary to ensure that the design has qualitative characteristics of rigidity.

See also: How to make the engine preheater itself

After all, during installation or further operation, a poor-quality tuning product can not only collapse by itself, but also cause damage to the machine, including someone else’s. Also, the mount should provide a secure fit and eliminate the loss of body kit.