The problem of any modern car is the lack of space in the trunk. With daily trips it is not so noticeable, but when you are going on a long journey or on vacation, the problem of placing luggage becomes a headache for many car owners. Car manufacturers are familiar with this problem, they are fighting for every cubic centimeter of trunk volume, but it is still not enough. In most cases, the problem is solved by installing an additional trunk on the roof of the car.

Content

- 1 A little about the car trunk

- 2 Preparatory stage

- 2.1 What to do the trunk

- 2.2 We make measurements

- 3 Getting Started

- 4 Advantages and disadvantages

A little about the car trunk

Homemade trunk is very convenient to install on rails

Recently, the trunk type "autobox" has become very popular. Its main advantages are the streamlined shape, which to a much lesser extent affects the aerodynamic performance of the car, as well as reliable protection of the luggage being carried from the influence of weather conditions.

Modern cars rarely go on sale with regular roof racks. However, the place to install them is still provided. The cost of devices for transportation, even from a little-known manufacturer, is quite high, not to mention well-known brands. Therefore, if you have to use the product several times a year, then you can make a roof rack on your roof with your own hands, having basic metalworking skills.

Preparatory stage

What to do the trunk

Material for the manufacture of the trunk should be quite light and at the same time durable. Ideal for this aluminum and its alloys. The material is lightweight, can withstand sufficient loads, does not corrode, but has a significant drawback at home it is quite difficult to work with. Therefore, most motorists prefer this work thin-walled steel profile. And the last option - the use of sheet "stainless steel". Often, it is preferred because of its strength and flexibility, while losing sight of the fact that a product made from such a material has a significantly greater weight than a similar one made from aluminum or a steel profile.

We make measurements

The bottom of the trunk is made in the form of a lattice for greater strength

Before starting work, you should make accurate measurements and draw up a drawing of the product. This will help determine the weight of the structure, approximately calculate the amount of materials needed, as well as calculate how much such a trunk will cost you. In the drawing it is better to immediately identify all the important elements of the future trunk - its frame, the number and location of jumpers, sides, as well as the bearing bottom of the structure.

To reduce the resistance of such a product, it is also possible to make its front part more streamlined. This will help to reduce fuel consumption during the trip.

Getting Started

The approximate scheme of the work is as follows:

- We cut the selected profile with a grinder, according to measurements made earlier.

- Then, using a welding machine, we connect the profile along the perimeter in order to obtain the frame of the future product.

- We strengthen the resulting frame with previously prepared longitudinal bridges. To make the structure even more rigid, we join the jumpers by welding several more rows of jumpers across them. As a result, we should get a grille, which will play the role of the bottom of the trunk.

- To reduce air resistance, a special arc of sheet metal and a profile is welded to the front of the air. This device will improve the aerodynamics of the product.

- Boards should not be made very high - 10 centimeters is enough. For ease of use, it is better to make them removable, threaded connections here are the best solution. In order to prevent the bearing frame from collapsing into it, a sleeve is usually welded into it, for which a pipe of the appropriate diameter is used.

- The upper crossbar is almost completely repeats the shape of the frame and connects with him racks.

- Collected trunk should be protected from environmental exposure. Under the influence of moisture, not only the trunk itself is corroded, but also the drops that drip from it leave for the car hard-to-remove dirty stains. Before painting, the trunk should be treated with a grinder at the welding sites, and the rust cleaned with emery cloth or treated with chemical converters. Before painting, the structure should be carefully primed and allowed to dry for 24 hours. When choosing paint should take into account the color and what the car is painted. For example, on a black car the salad-colored trunk will look like a misunderstanding. In most cases, for the trunk choose the same color and type of paint, which is painted the car itself. Many motorists for these purposes choose paint in special cans. They do not require sophisticated equipment for high-quality painting, resistant to the effects of precipitation and mechanical damage.

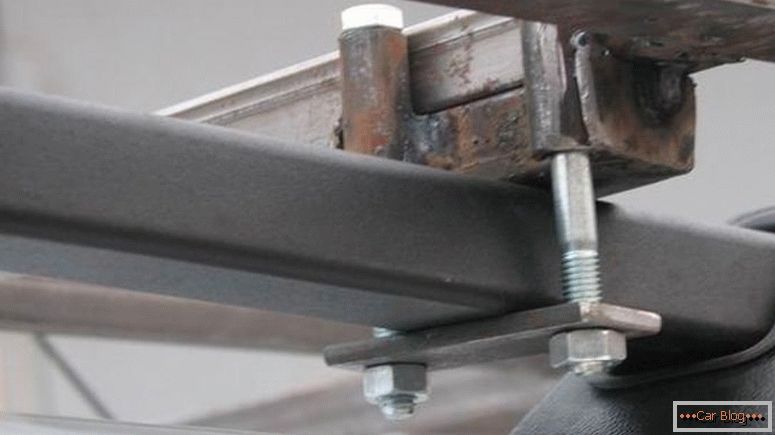

- Mounted a trunk in various ways. For cars equipped with roof rails problems with the installation of expeditionary trunk does not arise. In the case when rails are not provided, then, most likely, you will have to drill holes in the roof of the car. In fairness it should be noted that many manufacturers still leave special space for the installation of such devices.

Fastenings homemade trunk

Advantages and disadvantages

Mounted trunk rails with your own hands can be equipped with additional equipment. In front of the trunk, you can provide a mount for a fog of protivotumanok, which can be used on country roads. At the rear of the assembled structure, it is possible to provide a platform for mounting a fixed antenna for a radio receiver or a TV. To accommodate the shovel and hijack can be provided for mounting on the outer or inner side walls. With frequent driving on forest roads, it is possible to provide in the design fasteners for vetkotboinikov, protecting the paintwork and glazing of the car from damage.

The trunk mounted on the roof of the car can be equipped with additional equipment, for example, "foglights"

You should be aware that, along with the existing advantages, forwarding trunks also have a number of disadvantages that reduce the operational performance of the car and its safety. A car with a trunk installed increases fuel consumption due to increased aerodynamic drag. This becomes especially noticeable at speeds above 60 km / h. Airflows that form around the trunk, create additional noise in the cabin. An unevenly distributed load can lead to a deterioration in machine handling. But the biggest danger lies in the fact that the center of gravity of the car is shifted, and this can lead to the car tipping over when skidding or sharp turning at speed. Therefore, experts recommend that the trunk on the roof of the car to make removable and use it only when necessary.

See also: Connection diagram of the subwoofer and amplifier to the radio tape recorder