Winter time is quite problematic for car maintenance. During this period, lubricants, technical fluids and fuels have a higher viscosity due to a decrease in ambient temperature. To bring them to the optimum state, it is recommended to use the engine preheater 220V.

This practice will reduce the power load on the mating structural elements. The engine will start faster and the active wear of parts will also decrease. Installing a 220V engine heater is recommended from the time when the ambient temperature drops to +10C. The presence of an additional heating unit will allow the engine to start up already warmed up.

Content

- 1 General information

- 2 Choosing the right product.

- 3 The presence of a pump in the machine

- 4 Without built-in pump

- 5 Installation method on passenger cars

general information

The effective electric heating of the engine in winter is based on an increase in the temperature of the coolant (antifreeze) that circulates through the technical channels of the cylinder block. Installed additional equipment reliably copes with its task, ensuring high-quality operation of internal combustion engines for different types of transport:

- passenger cars;

- trucks of various modifications;

- bus fleet.

Manufacturers offer designs of their models, which can be equipped with an electric pomp, or do not have a similar node in a cheaper version. In any case, this equipment needs to be connected to a household electrical outlet. Often it is used in indoor paid parking lots or in a personal garage. Less often, open parking spaces have remote stationary racks with sockets.

Products manufactured by popular manufacturers have a high degree of protection. They can be left on all night or day and not be afraid of any accidents. WITHThe modern car engine heater 220V is equipped with an automatic node for switching off the heating when the set temperature condition is reached. As soon as the working fluid cools again to the threshold level, the device starts up again.

Choosing the right product

Before you install a 220V engine heater, you need to determine its parameters. To navigate in this situation, you need the presence / absence of the pump and the power characteristics of a particular product. The latter are selected in accordance with the volume of the motor. Common to all designs are such advantages:

- saves fuel that is spent on heating without a heater;

- high degree of fire safety;

- simple operation;

- compactness.

Even the largest built-in copies with modest dimensions weigh only a couple of kilograms.

The presence of a pump in the machine

Models with heaters by electropumps allow the fluid to run through the channels during the heating process. Such functionality provides higher efficiency of thermal equipment. At the same time there is a saving of time to achieve the specified parameters.

After switching on to the power grid, the heating element built into the heater body begins to warm up. At the same time, the electric pump starts, sending warm antifreeze to the channels through the outlet. A cool liquid flows from the cylinder block through the inlet to the heating element. Thus, the flow is carried out along a closed loop.

See also: Isofix fastening system in the car: photo

It is important to know that the thermostat is provided in the design of the preheater, which periodically turns off / on the circulation and heating, keeping the temperature of the liquid in the specified range.

Usually at +70With double-sided models of heaters takes about 30-50 minutes. The exact time depends on the ambient temperature and external weather factors, which include the presence of wind in the open parking, precipitation, etc. In the garage or box conditions, the car warms up faster. After that, the car is ready for operation.

The advantages of pump design are the following factors:

- less time spent on heating than non-bombs;

- the temperature increase occurs with the entire motor more evenly, since the channels cover the entire unit;

- no thermal distortions during the initial cycle are allowed.

The disadvantages of these products are the following features:

- the additional power of the device is spent on moving the liquid, so for most models this parameter cannot be lower than 1.5 kW, otherwise it will not be possible to bring the liquid to the desired operating mode;

- the presence of a circulating pump increases the cost of the product, and also increases the likelihood of its failure due to the presence of an additional node;

- the appliance consumes more energy, which affects operating costs;

- Some models require the connection of a pump to an additional 12 V supply, for example, from a battery.

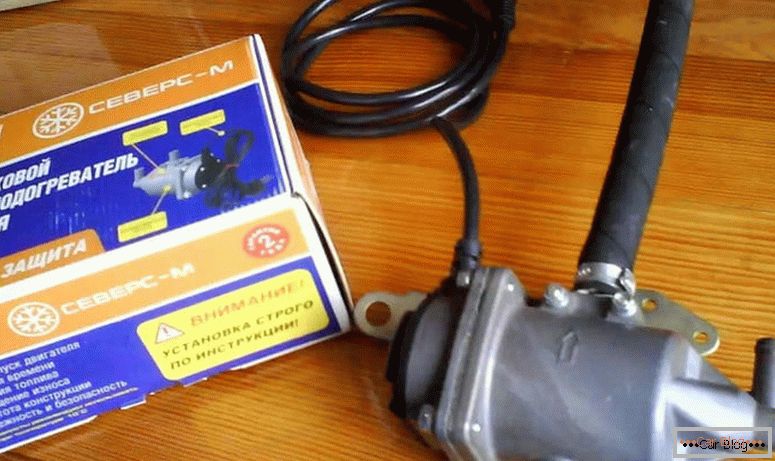

A popular model of this type is the Severs + device. It is offered to buyers in a two-kilowatt modification. The device comes complete with a universal mounting kit. Attached is a detailed written briefing and important details for joining the motor. Characteristics of the device:

- dimensions of the finished assembly 86x86x180 mm;

- cord to connect 150 cm;

- power is 2 kW;

- consumed current 220 V 50 Hz;

- external coating anodized protective aluminum;

- built-in thermostat, triggered at 80WITH;

- shutdown occurs at 140WITH;

- sealed enclosure prevents penetration of the heated fluid to the electrical components.

The device is certified and meets all electrical safety requirements.

Design features:

- horizontal type of installation does not allow the penetration of antifreeze to the electrical part, increasing the safety of operation;

- built-in ball valve forms a flow for the circulation of fluid through the heating element in the right direction;

- the thermostat keeps the liquid in the desired mode;

- thermal switch is an additional protection against possible malfunction of the thermostat.

We recommend choosing models with a bumper connector. This feature allows you to quickly connect the equipment without opening the hood. The plug is usually in such a situation attached behind the grille or in the area of the bumper.

See also: How to install parking sensors yourselfWithout built-in pump

Покупателям доступен heating the cooling system before starting the engine 220V в комплектации без электропомпы. Он является более распространенным типом данного оборудования. Такие агрегаты не нуждаются в дополнительном обслуживании, но при этом обладают высокой степенью надежности.

The advantages of bespomovy models include factors:

- stable performance in all conditions;

- Connect exclusively to a household outlet;

- simplicity of installation of the device to the block of cylinders;

- reduced power consumption by the device.

The disadvantages of this scheme are:

- the circulation is carried out solely due to the temperature difference, passing mainly in a small circle;

- it takes a longer time to warm up;

- you need to carefully choose the model, as there are poor-quality copies.

An example of such models is the production of Hotstart series CB, CL, SB, SL. They are in demand in cars with diesel engines of high power. The body is made of durable aluminum alloy, die-cast. Connect devices from a network of 220 V or 380 V.

Installation method on passenger cars

Installation of preheater engine 220V is carried out at the bottom of the cylinder block. In this part there is a screw plug. In VAZ models, it is convenient to use the area around the Langeron, where a beam is attached to it. Most mounting kits have special brackets.

Important! You must first drain the coolant, as the system will be depressurized.

The body of the heater has a pointing arrow indicating the point of entry of the liquid into it. This pipe must be connected to the outer jacket of the power plant. From this hole, the antifreeze will pass into the channels of the unit, and then move to the upper nozzle that goes to the pump from the radiator.

The kits have a special fitting. It must be screwed in place of the drain threaded screw (plug). The top branch pipe is cut and divided with the help of a tee. It is important not to confuse the direction of fluid flow, since the technological angle of inclination allows the antifreeze to move freely through the updated system of channels.

After all the pipes are mounted, we pour antifreeze into the system and monitor the tightness of the joints and the sealing of clamps. We test the heating of the installed thermosystem.

Mounted engine liquid heaters are more profitable devices, compared to stationary bulky models. They are also more economical in energy consumption and have a lower price tag. The wide distribution of such equipment proved its effectiveness in the operation of cars of different classes.