There is a ball bearing on any cars - both on front-wheel drive with MacPherson-type suspension, and on rear-wheel drive ones. This is an element of the suspension, through which the front wheel hub is rotated relative to the body. For example, in the old classic-class vases, there are two ball bearings - on the upper and lower arms. Between them there is a hub, to which the tie rods are attached. The look of this part is quite simple - the lower part is made in the form of a thick washer of steel with a thickening of a spherical shape in the center. Inside, this thickening is hollow, so a tip is placed there during the manufacture of the support. On the one hand, it has the shape of a ball, on the other - a cone and threads on the edge.

А теперь постарайтесь представить неприятную картину – шаровая опора разлетается на две части. Что тогда произойдет? Ничего хорошего, так как колесо будет стоять не четко вертикально, а под углом к поверхности и упираться в кузов. И если вам кто-то вдруг расскажет историю, что после того, как распалась шаровая опора, он доехал благополучно до места ремонта, то не верьте этому человеку. Поможет только услуга эвакуатора или замена узла в полевых условиях. Если есть, конечно, он в запасе или в пределах видимости находится магазин с автозапчастями. Но чтобы не попасть в такую неприятность, необходимо следить за состоянием подвески и своевременно выявлять недочеты. Очень важно знать, how to check the ball bearing самостоятельно.

First signs of breakage

The appearance of the ball bearing of the car

When driving a car, you hear a slight crunch or a light tapping - this is the first sign of a malfunction. It is especially noticeable when cornering. Very often, too easy steering or increased play accompanied by a knock. The main thing - not to be confused with the failure of the CV joints, because when the steering wheel is turned all the way out at the beginning of the movement, they also emit a nasty crunch. If you believe the books, the ball bearings are eternal (provided that they always have lubricant, and operation takes place in normal conditions). Perhaps this mode of operation - it is lying on the counter in the store.

See also: How to change the front shock absorbers with your own handsIn fact, during operation, the integrity of the anther is broken. Rubber, from which it is made, is constantly under the influence of dirt and water. Over time, the surface of the anther dries out, it becomes covered with microcracks, which then turn into full-fledged holes. And then the small particles get inside the ball, gradually breaking the metal. In the end, you will hear unpleasant crunches and tapping. In fact, nothing more is needed to get the ball out of order, it is enough to keep dirt and dust. And the result of such a breakdown is an increase in the backlash and the probability of jamming. In the latter case, it will not work to turn the steering wheel, no matter how much effort you put on it.

The initial ball check can be carried out almost with “bare hands”

Diagnose footing

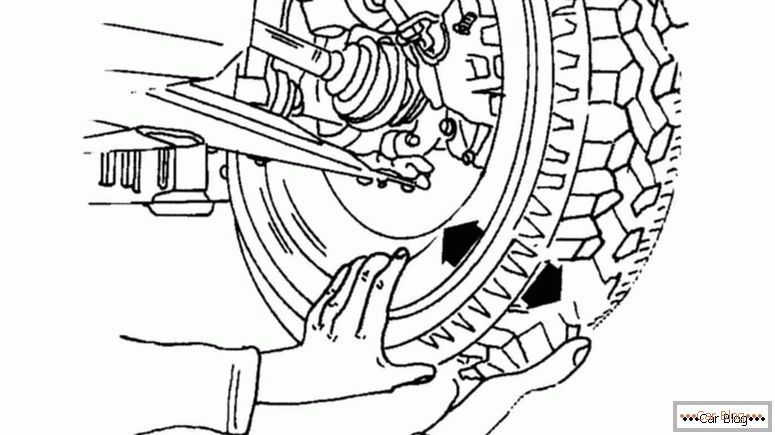

There are two ways to check - visual and mechanical. In the first case, only a survey. In its process, you identify cracks and holes on the anther, assess the condition. If there is damage, it is necessary to replace the rubber boot. More complete information about the condition of the suspension can only give a diagnosis by mechanical means. For this it is necessary to use a pit, a lift or a flyover. First, try to pull the wheel with your hands, taking it by the top and bottom. For a more accurate diagnosis, you will need the help of the mount - install it between the hub and the suspension arm. If there is any play, you will immediately feel it.

The consequences of the failure of a ball bearing, especially at speed, can be very deplorable.

It is possible to remove the hub from the ball of the ball bearing and check the play. If there are problems, then the finger will easily rotate around its axis and from side to side. In this case, it is best to replace, and do not try to use old anthers on the new part. Replacing and checking the ball bearing is simple, no one should have difficulties. But if you have never encountered such a procedure, then it is better to visit the service station for the first time or ask an experienced friend to help. Carefully look at how this work is done, what tools and fixtures should be used. But the next time it will be possible to do this thing yourself.

See also: Replacing the front wheel bearing